DC

ELECTRICAL

SYSTEM

DESCRIPTION

The

DC

Circuit functions to start, operate and stop the

gener~

ator's engine. The circuit

is

best understood

by

reviewing the

DC

ELECTRICAL

SYSTEM

WIRING

DIAGRAMS.

The

engine's

DC wiring

is

designed with three simple basic

circuits:

preheat, slart, and

run

or stop.

Engine

12-Volt

Control

Circuit

The engine has a ] 2 volt DC electrical control circuit that

is

shown in the wiring diagrams. Refer

to

these diagrams when

troubleshooting or when servicing the DC electrical system

on the engine.

A

CAUTION:

To

avoid

damage

to

the

battery

charg-

ing

circuit,

never

shut

0"

the

engine

battery

switch

while

the

engine

is

running.

Shut

off

the

engine

battery

switch,

however,

to

avoid

electrical

shorts

when

working

on

the

engine's

electrical

circuit.

CHARGING

SYSTEM

The charging system consists

of

an alternator, a voltage

regulator, an engine DC wiring harness,

an

engjne~mounted

DC

circuit breaker, a battery and connecting wires. Because

of

the use

of

integrated circuits (IC's) the electronic voltage

regulator is very compact and

is

mounted internally

or

on the

back

of

the alternator.

ALTERNATOR

TROUBLESHOOnNG

If you suspect that

the

alternator

is

not

producing enough

voltage

to

charge the engine's battery, check the following:

A

WARNING:

A

failed

aftemator

can

become

very

hot.

Do

not

touch

until

the

alternator

has

cooled

down.

o

Make

certain your alternator

is

securely mounted.

o Check the drive belts for proper tension.,

o Inspect for loose

or

disconnected wires at the alternator.

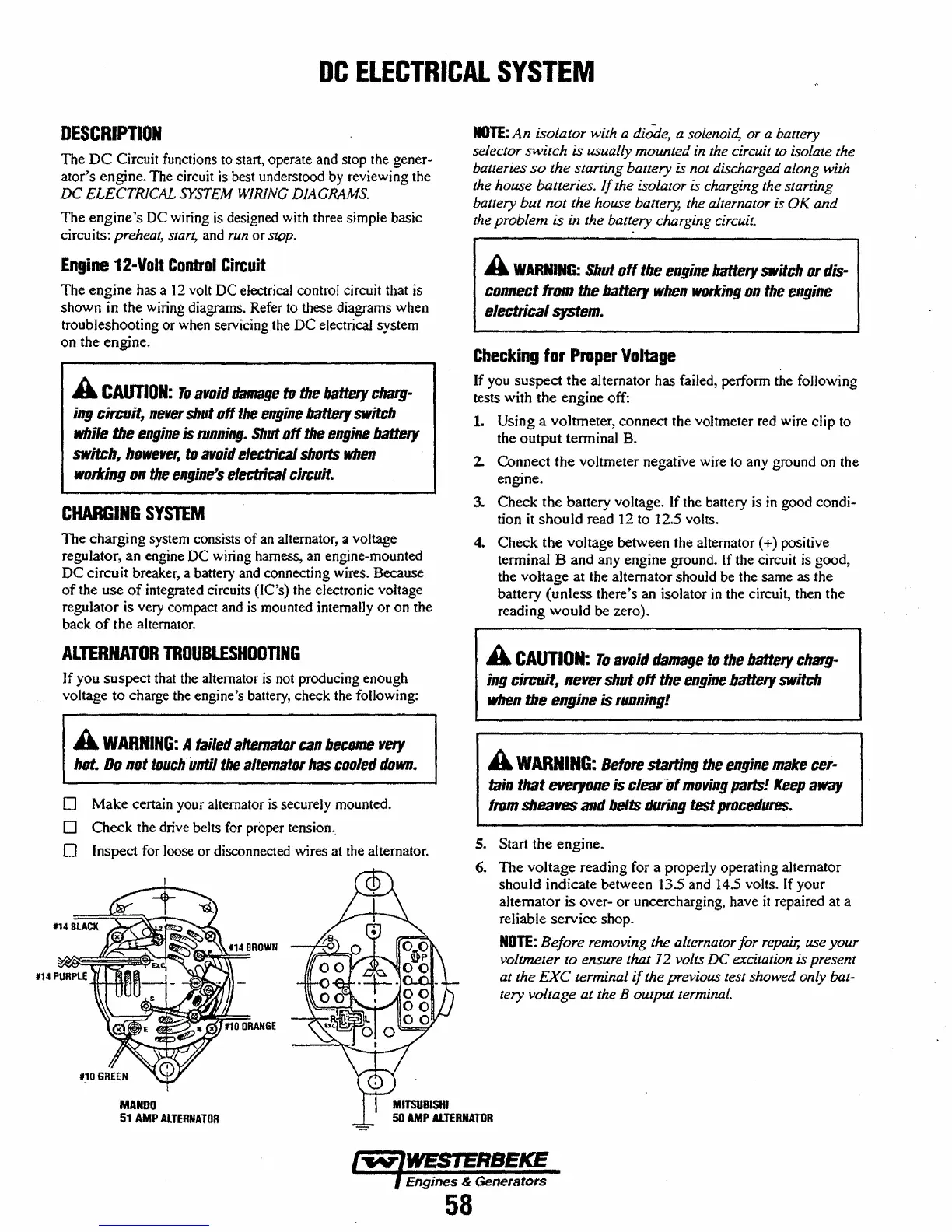

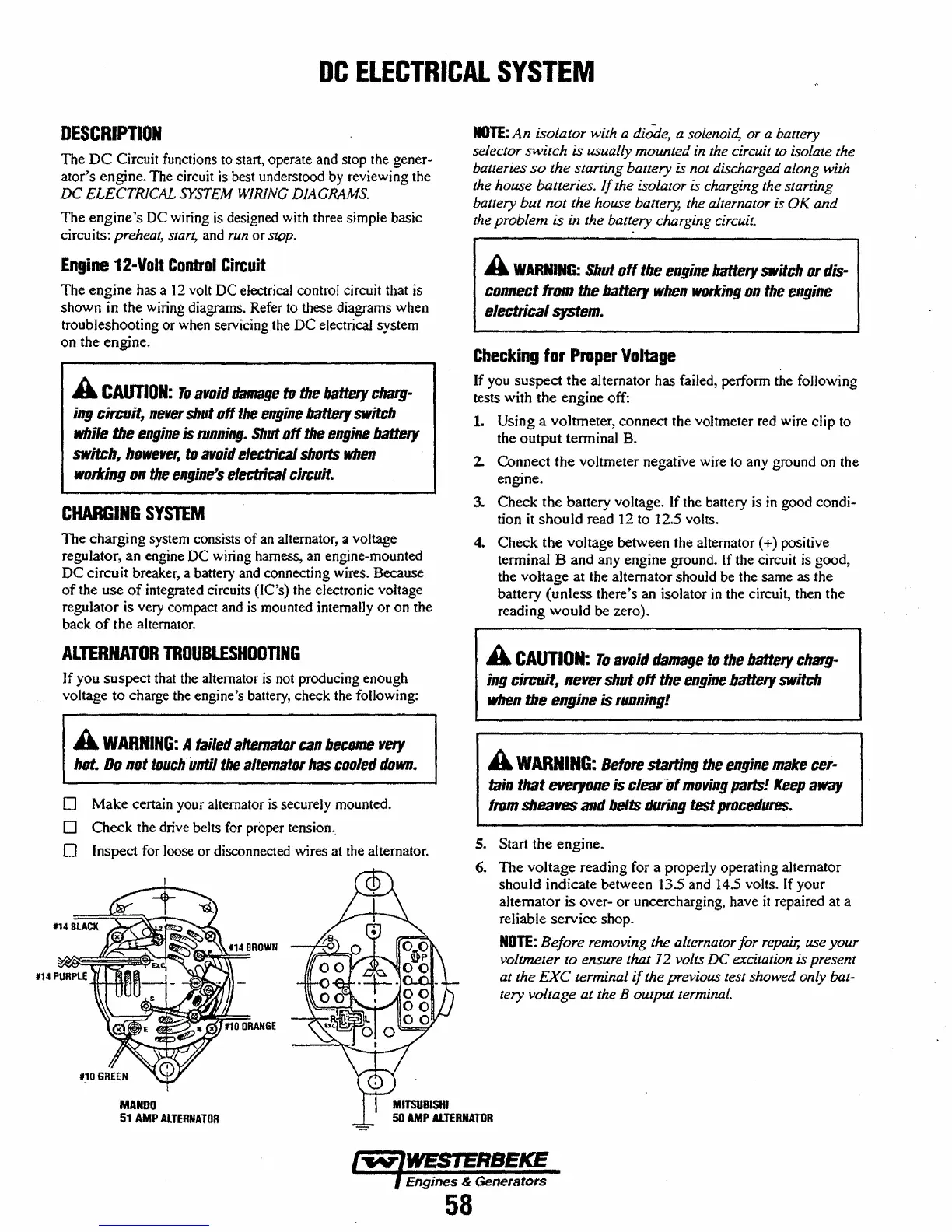

MANDO

51

AMP

AlTERNATOR

NOTE:

An

isolator with a diode, a solenoid, or a ballery

selector switch

is usually mounted

in

the circuit to isolate the

balleries

so

the

starling battery is not discharged along with

the house batteries.

If

the isolator is charging the starting

battery

but

not

the house battery, the alternator is

OK

and

the problem

is in lhe battery charging circuit.

A

WARNING:

Shut

off

the

engine

battery

switch

or

dis-

connect

from

the

battery

when

working

on

the

engine

electrical

system.

Checking

for

Proper

Voltage

If you suspect

the

alternator has failed, perform the folJowing

tests with the engine off:

1. Using a voltmeter, connect the

voltmeter red wire clip to

the

output

terminal B.

2. Connect

the

voltmeter negative wire to any ground on the

engine.

3. Check the battery voltage. If the battery is

in

good

condi~

tion

it

should

read

]2

to 12.5 volts.

4.

Check the voltage between the alternator (+) positive

terminal B and any engine ground. If the circuit

is

good,

the voltage at the alternator should be the same as the

battery (unless there's an isolator

in

the circuit, then the

reading

would

be zero).

A

CAUTION:

To

avoid

damage

to

the

battery

chalg

..

ing

citeuit,

never

shut

off

the

engine

battery

switch

when

the

engine

is

running!

A

WARNING:

Before

stalfing

the

engine

make

cel-

fain

that

everyone

is clealof

moving

parts!

Keep

away

from

sheaves

and

belts

during

test

procedures.

5. Start the engine.

6. The voltage reading for a properly operating alternator

should indicate between

13.5 and

14.5

volts. If your

alternator is over-

or

uncercharging, have

it

repaired at a

reliable service shop.

NOTE:

Before

removing the alternator for

repair,

use

your

voltmeter to ensure

that]

2 volts

DC

excitation is present

at the

EXC

lerminal

if

the previous test showed only bat-

tery vollage at the B oUlput terminal.

Engines & Generators

58

Loading...

Loading...