CYLINDER

BLOCK

SERVICE

DISASSEMBLY

1. For removal

of

a the cylinder head and related parts, refer

to

DISASSEMBLY under CYLINDER HEAD SERVICE.

2. For removal

of

the water pump and electrical equipment,

refer to their respective sections.

3. Pull off the push rods, then pull out the tappets upward.

4. Remove the fuel filter.

5. Loosen the crankshaft pulley nut, then take off the pulley

and washer.

6. Loosen the flywheel mounting bolts and remove the fly-

wheel.

7.

Remove the back plate and rear oil seal case.

8. Remove the lube oil pump gear bearing housing. Remove

the gear case, but first

it

is

necessary to remove the tie-

rod located

at

the right front (beside the injection pump)

of

the cylinder block and to remove the stopper spring

and tie-rod from the injection pump's fuel rack.

A

CAUTION:

Be

sure

tD

separate

the

injection

pump

rack

from

the

tie-rod

before

removing

the

gear

case.

The

front

plate

is

bolted

to

the

cylinder

block

frDm

inside

the

gear

case;

therefore,

be

care-

ful

nDt

tD

drive

Dut

the

gear

case

tDgether

with

the

front

plate.

Also,

be

careful

not

to

damage

the

dowel

pins.

9. Remove the fuel injection pump.

10. Remove the governor weight bolts. Remove the weights.

11. Remove the pump camshaft bolt.

12. Remove the oil filter and the oil pump assembly. Then

pull out the injection pump camshaft.

13. Remove the gears. Then remove the front plate.

14. Remove the camshaft.

15. Turn the engine upside down. Remove the oil pan and oil

screen.

16. Remove the nuts from the big end

of

each connecting rod

and remove the cap. Push the piston and connecting rod

assembly upward out

of

the cylinder block. Keep

Hie

removed parts in order for each cylinder. When pushing

out the piston and connecting rod assembly, put a

wooden block against the cap mating surface

of

the rod

so as not to damage the metal surface.

17. When separating the piston from the connecting rod, use

the following procedures. Keep the disassembled parts

in

order for each set. Take care to prevent confusion, espe-

cially for each set

of

piston and wrist pin.

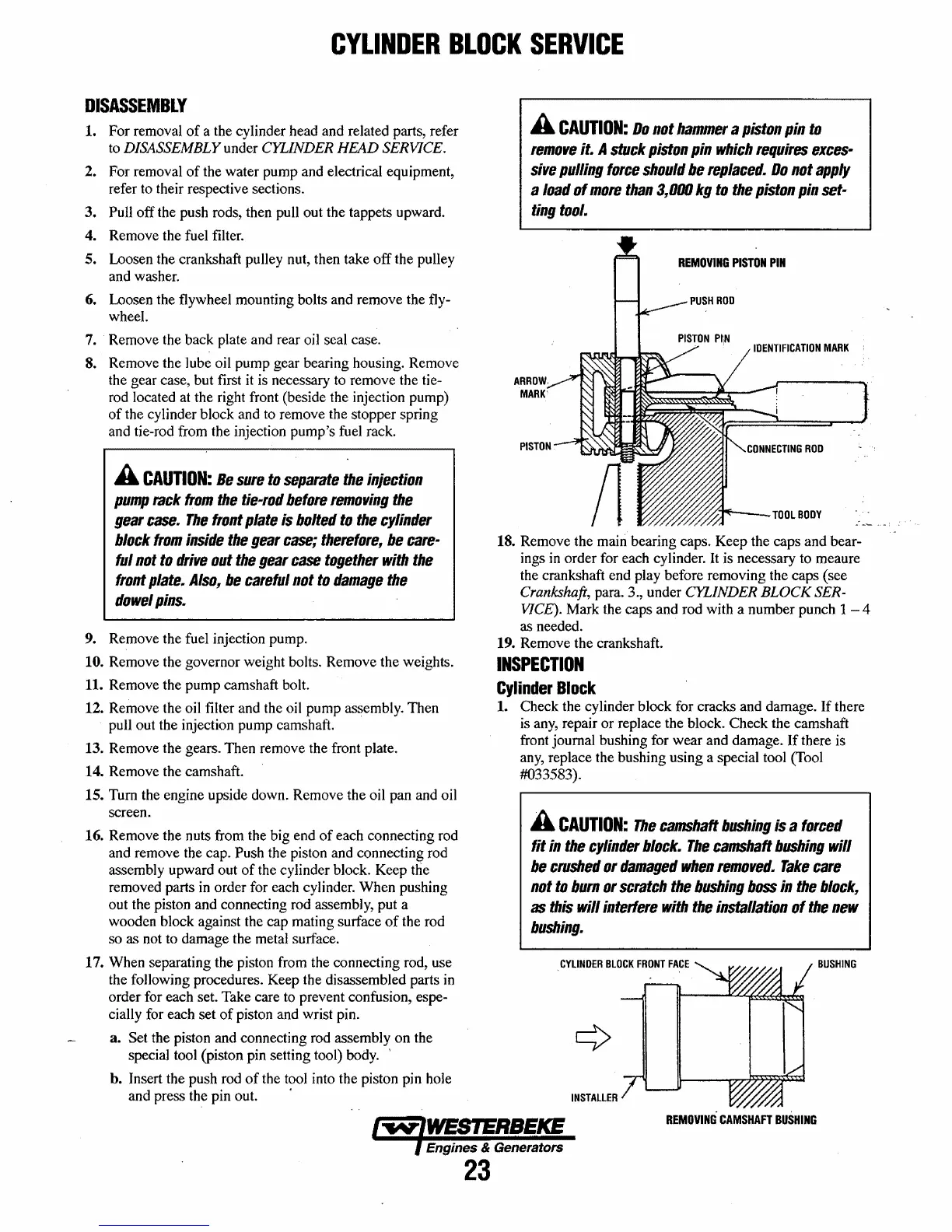

a. Set the piston and connecting rod assembly on the

special tool (piston pin setting tool) body. '

h. Insert the push rod

of

the tool into the piston pin hole

and press the pin out. .

A

CAUTION:

Do

not

hammer

a

piston

pin

tD

remDve

it. A

stuck

piston

pin

which

requires

exces-

sive

pulling

force

should

be

replaced.

Do

not

apply

a

IDad

of

mDre

than

3,000

kg

tD

the

pistDn

pin

set-

ting

tool.

REMOVING

PISTON

PIN

IDENTIFICATION

MARK

"///'//./~~---TOOL

BODY

18. Remove the main bearing caps. Keep the caps and bear-

ings

in

order for each cylinder. It is necessary to meaure

the crankshaft end play before removing the caps (see

Crankshaft, para. 3., under CYLINDER

BLOCK

SER-

VICE). Mark the caps and rod with a number punch 1 4

as needed.

19. Remove the crankshaft.

INSPECTION

Cylinder

Block

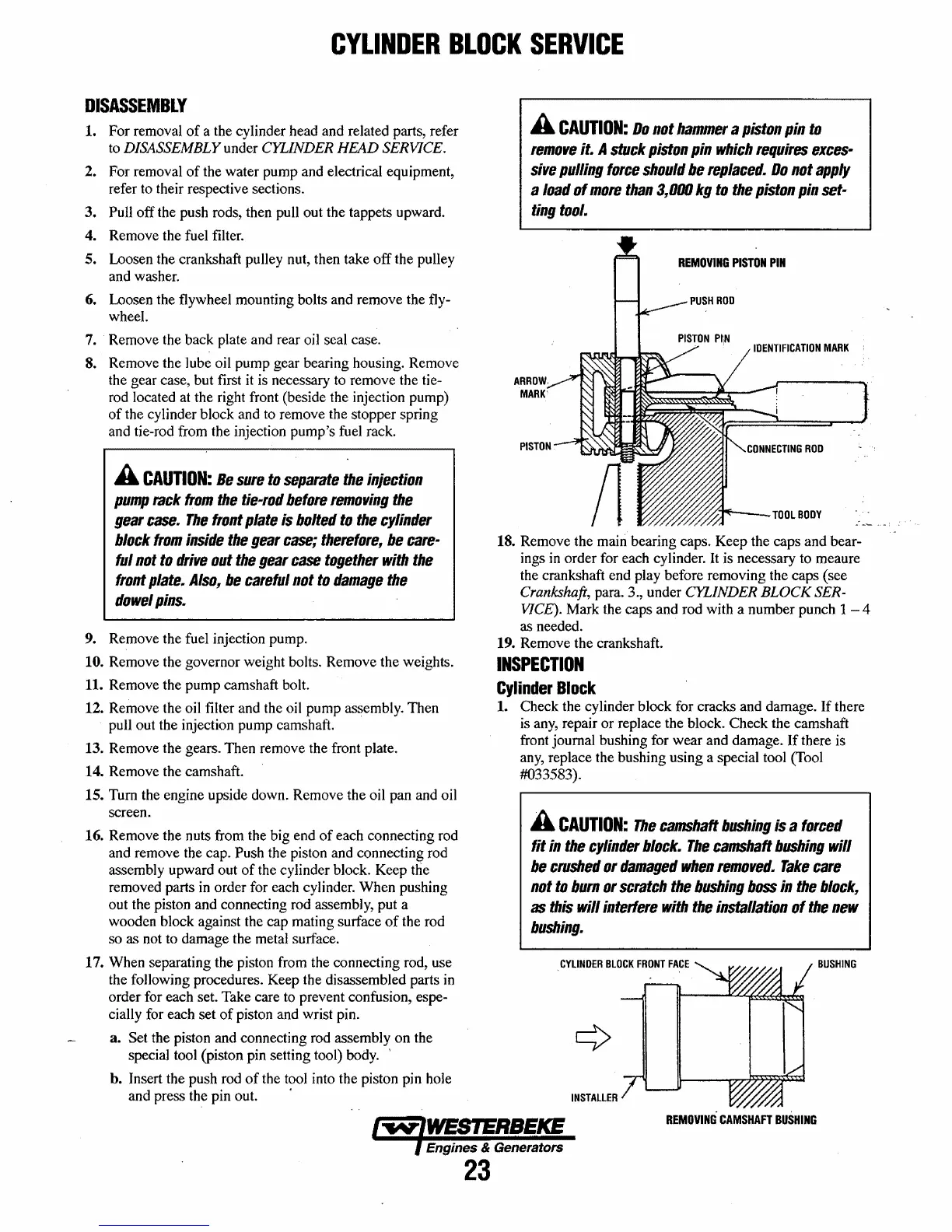

1. Check the cylinder block for cracks and damage. If there

is

any, repair or replace the block. Check the camshaft

front journal bushing for wear and damage.

If

there is

any,

replace the bushing using a special tool (Tool

#033583).

A

CAUTION:

The

camshaff

bushing

is a

fDrced

fit

in

the

cylinder

block.

The

camshaff

bushing

will

be

crushed

or

damaged

when

removed.

Take

care

not

to

burn

or

scratch

the

bushing

boss

in

the

block,

as

this

will

interfere

with

the

installation

of

the

new

bushing.

BUSHING

REMOVING

CAMSHAFT

BUSHING

Engines & Generators

23

Loading...

Loading...