STARTER/SOLENOID

SERVICE

STARTER

INSPECTION

Solenoid

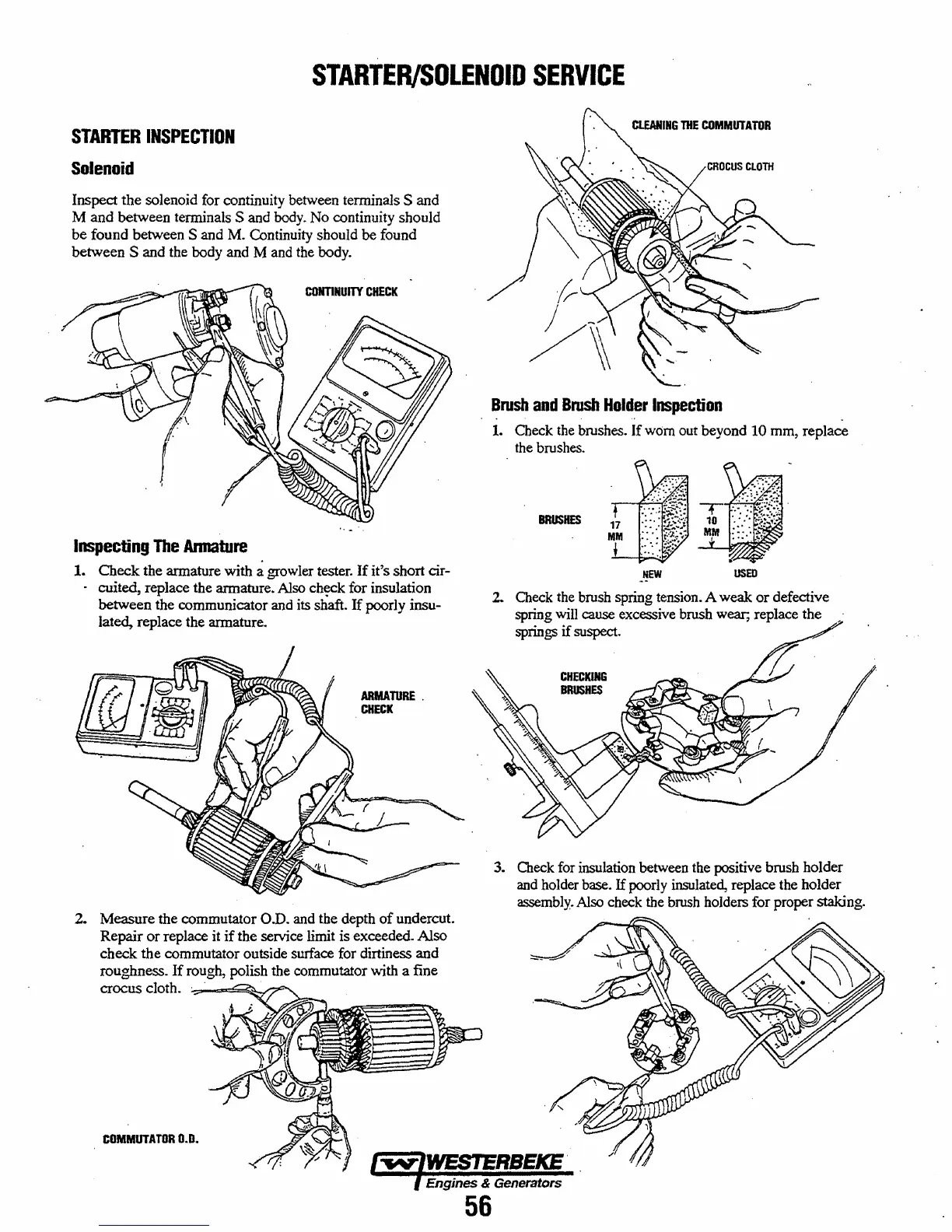

Inspect the solenoid for continuity between terminals S and

M and between terminals

S and

body.

No

continuity should

be found between

Sand

M. Continuity should be found

between

S and the body and M

and

the

body.

COmNUITY

CHECK

......

'

Inspecting

The

Annature

1. Check the armature with

~

growler tester.

If

it's short

dr-

. cuited, replace the armature. Also

ch~ck

for insulation

between the communicator

and

its

shaft. If poorly insu-

lated, replace the armature.

ARMATURE.

CHECK

2. Measure the commutator

0.0.

and

the depth

of

undercut.

Repair or replace

it

if the service limit

is

exceeded.

Also

check the commutator outside surface for dirtiness and

roughness.

If

rough, polish

the

commutator

with

a fine

crocus cloth.

COMMUTATOR

O.D.

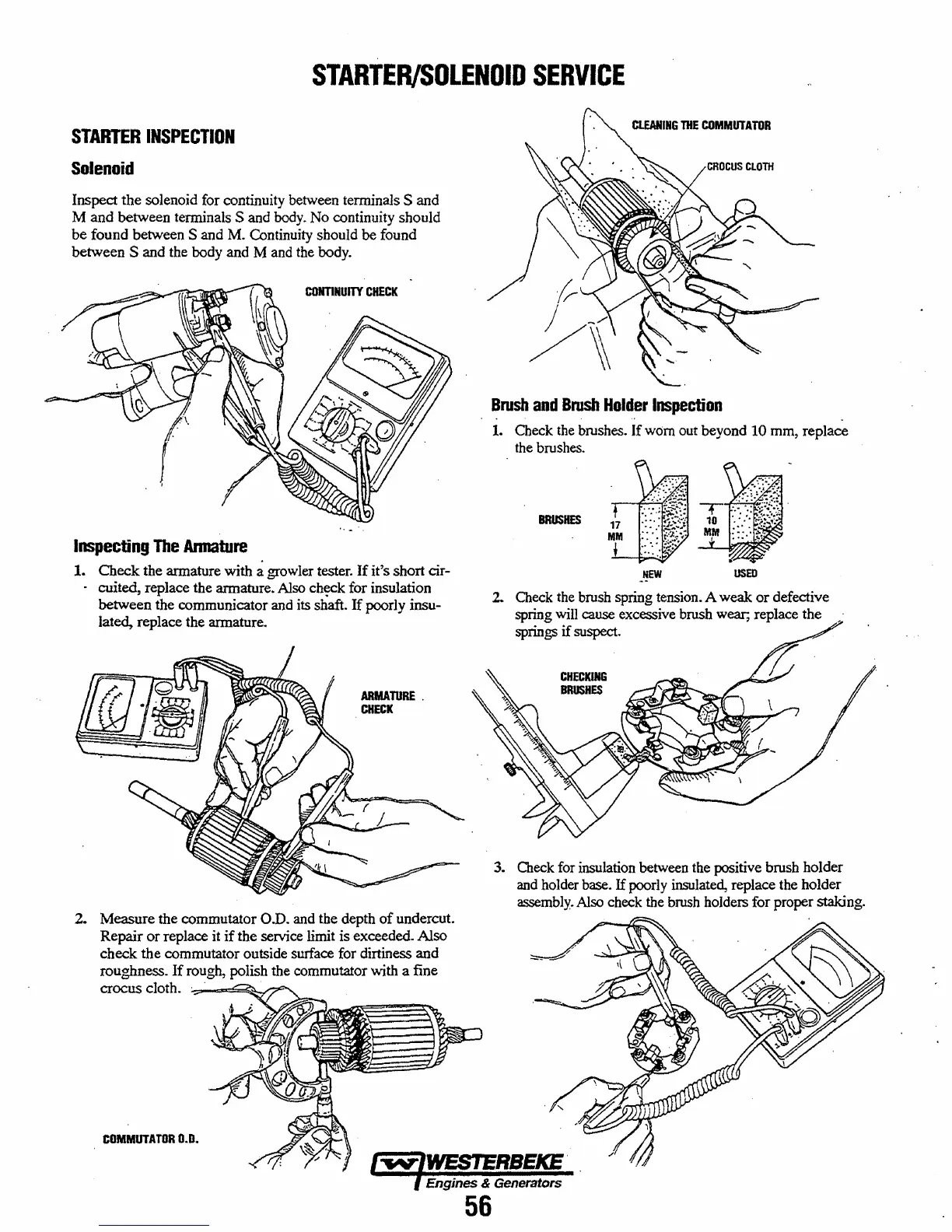

CLEANING

THE

COMMUTATOR

Brush

and

Brush

Holder Inspection

1.

Check

the

brushes. If

worn

out

beyond 10

mm,

replace

the

brushes.

BRUSHES

_~EW

USED

2.

Check

the

brush

spring tension. A weak or defective

spring

will

cause excessive

brush

wear; replace the

springs

if

suspect.

3.

Check

for

insulation

between

the

positive brush holder

and

holder

base.

If

poorly

insulated,

replace the holder

assembly.

Also

check

the

brush

holders for proper staking.

Engines & Generators

56

Loading...

Loading...