CYLINDER

BLOCK

SERVICE

Connecting

Rod

1. Using a connecting rod aligner, check each connecting

rod for bending and distortion. If necessary, correct or

replace the rod.

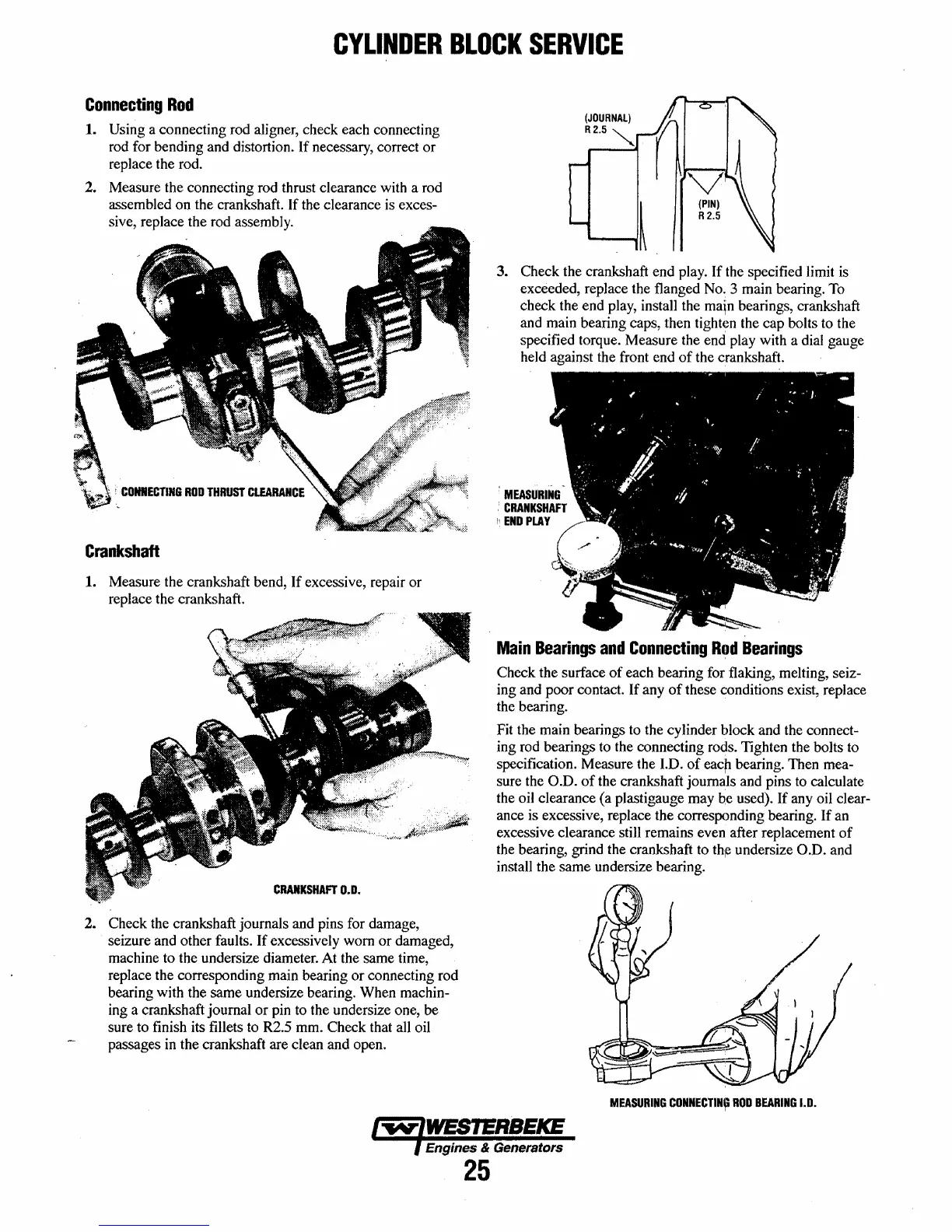

2. Measure the connecting rod thrust clearance with a rod

assembled on the crankshaft. If the clearance is exces-

sive, replace the rod assembly.

!

CONNECTING

ROD

THRUST

CWRANCE

Crankshaft

1. Measure the crankshaft bend, If excessive, repair or

replace the crankshaft.

CRANKSHAFT

0.0.

2. Check the crankshaft journals and pins for damage,

seizure and other faults.

If

excessively worn or damaged,

machine to the undersize diameter. At the same time,

replace the corresponding main bearing or connecting rod

bearing with the same undersize bearing. When machin-

ing a crankshaft journal

or

pin to the undersize one, be

sure to finish its fillets to R2.S mm. Check that all oil

passages in the crankshaft are clean and open.

(JOURNAL)

R2.5~

(PIN)

R

2.5

3. Check the crankshaft end play. If the specified limit

is

exceeded, replace the flanged No

..

3 main bearing.

To

check the end play, install the

ma~n

bearings, crankshaft

and main bearing caps, then tighten the cap bolts to the

specified torque. Measure the end play with a dial gauge

held against the front end

of

the crankshaft.

Main

Bearings

and

Connecting

R"d

Bearings

Check the surface

of

each bearing for flaking, melting, seiz-

ing and poor contact. If any

of

these conditions exist, replace

the bearing.

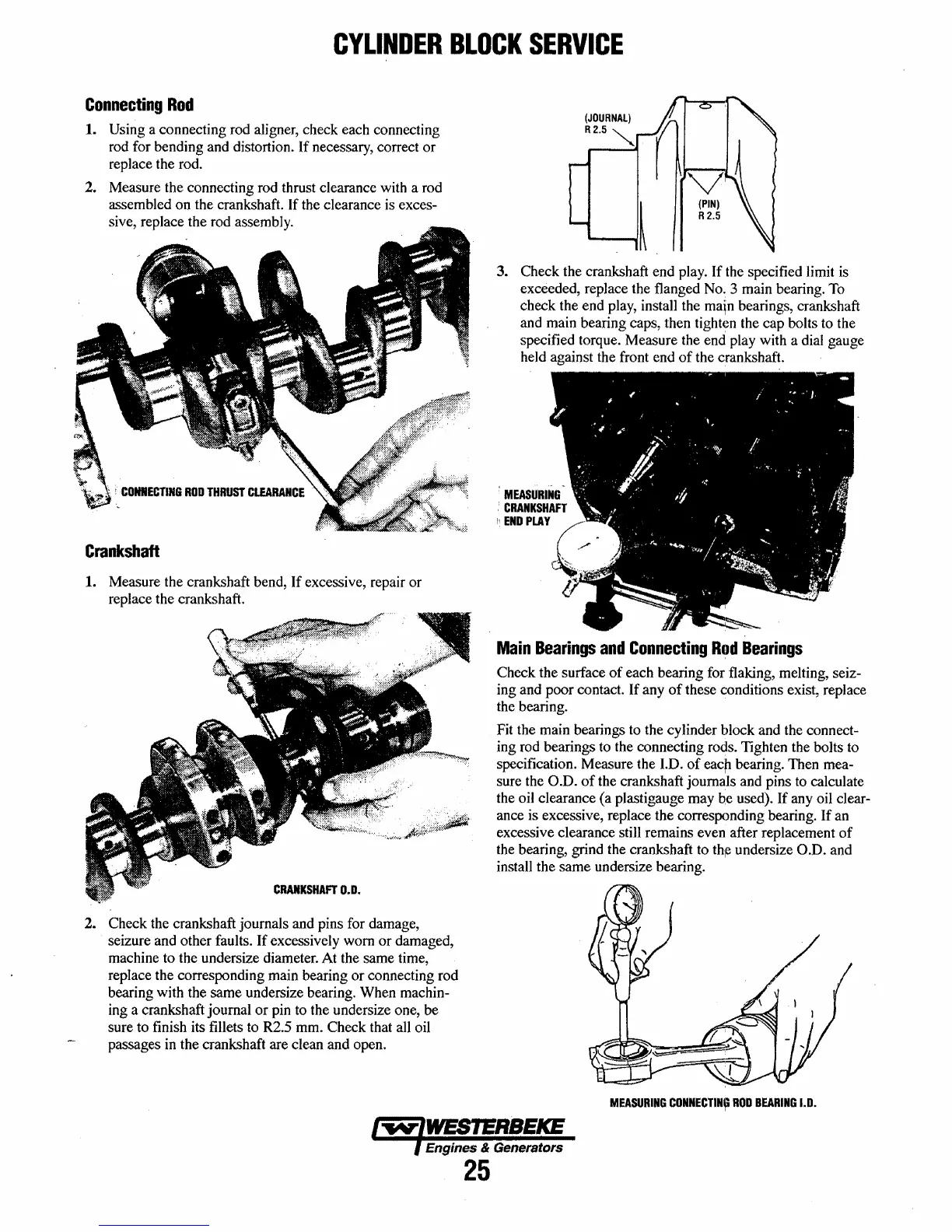

Fit the main bearings to the cylinder block and the connect-

ing rod bearings to the connecting rods. Tighten the bolts to

specification. Measure the

J.D.

of

eac~

bearing. Then mea-

sure the

0.0.

of

the crankshaft journals and pins

to

calculate

the oil clearance (a plastigauge may be used). If any oil clear-

ance is excessive, replace the corresponding bearing.

If

an

excessive clearance still remains even after replacement

of

the bearing, grind the crankshaft to

th!f!

undersize

0.0.

and

install the same undersize bearing.

MEASURING

CONNECTIN~

ROD

BEARING

1.0.

Engines & Generators

25

Loading...

Loading...