WMD

GENERATOR

DESCRIPTION

The

WMD

model generator is a self-exciting and self-regu-

lating brush style generator, requiring only a driving force to

produce voltage. It is four lead reconnectable for 115 volts or

115/230 volts, and has a four pole revolving armature with

no

DC

brushes

or

commutator.

It

has a solid state bridge rec-

tifier

in

the exciter circuit, AC slip rings, a drip-proof con-

struction, and a single bearing design. Voltage regulation is

7% no-load to full-load, and frequency regulation is

3-4

hertz no-load to full-load. It is

in

insulation class

"F"

as

defined by MEMA MGI-1.65, and it's temperature rise is

within MEMA

MGI-22.40 definition when operating at full-

load. It's centrifugal-type blower fan is direct connected

to

the armature shaft for cooling. Capacitors across the hot leg

and neutral minimize radio interference within the limits

of

most commercial and civilian applications. The armature is

balanced laminated steel, double dipped and baked. The field

ring is thick hot rolled steel with a welded bearing support

bracket, machined as an assembly for precise bearing align-

ment. The rear carrier bearing is pre-lubricated, double sealed

with an anti-rotation lock.

WMD

GENERATOR

SPECIFICATIONS

FREQUENCY

60

HERTZ

STANDARD

RPM

1800

for

60

Hertz

NOTE:

To

convert a 60 Hz

1500

for

50

Hertz

unit to 50

Hz,

the armature

must

be

changed.

Voltage

Normal

115VAG

230

VAG

Maximum

132

VAG

264

VAG

Minimum

108

VAG

216

VAG

Excitation

Voltage

115

VAG

(output

voltage

supplied

to

rectifier)

Field

Excitation

Voltage

190

VDG

(approximate)

DISASSEMBLY

1.

Lift and support the back end

of

the engine so that the

generator is not resting on its isolators.

2. Remove the generator endbell cover. This exposes the fan

and brush rig assembly. Remove the fan assembly with

its hardware.

3. Remove the brush rig assembly. This can be done in two

half assemblies.

Unbolt the two half-moon assemblies

from the frame attachment and lift the two halves away

from the slip rings. Mark the polarity

of

the two leads on

the bridge rectifier that go to the field coils and unplug

these from the bridge rectifier. The two half-moon brush

assemblies can be removed from the generator by remov-

ing the heavy output leads G 1, G2, G3 and G4 from their

attachment point on each brush holder. Make a rough

sketch as to where each

of

these leads attaches on each

assembly half. There are 8 leads that are paired

in

the

control panel to provide four reconnectable leads. Inspect

and replace components

in

the brush rig as needed. Do

not totally disassemble as this is not

n,eeded.

4. Remove the control panel from the top

of

the generator

housing. Mark all leads as needed for proper assembly.

5.

Unbolt the generator housing from the bell housing. A

puller may be needed at the bearing end to assist

in

pulling

the housing with or without the bearing off the armature.

Some gentle prying at the bell housing end will be needed

as well. The housing

with field coils is heavy. Once the

housing has cleared the armature shaft,

it

should be sup-

ported and slowly drawn over the armature. Try not to

drag

it

over the armature.

INSPECTION

1. Inspect the bearing and replace as needed. If the unit is

going through a major overhaul, bearing replacement is

recommended.

2. Check the field coils resistance values. Remove the field

coils from the housing. Note and mark each field coil's

position

in

the housing. Do not mix them

up!

Each coil has

a different part number and a specific position

in

the hous-

ing. Incorrect assembly will cause low voltage output.

3. Unbolt the armature from the flywheel. Test the armature

with an ohmmeter. Clean the slip rings and polish using a

crocus cloth.

REASSEMBLY

Reassemble

in

reverse order.

NOTE:

When

assembling

the

housing onto

the

generator

arma-

ture,

be

sure

to

properly

align

the

anti-slip

groove

in

the

bear-

ing

with

the hole

in

the

housing and install a new lock pin.

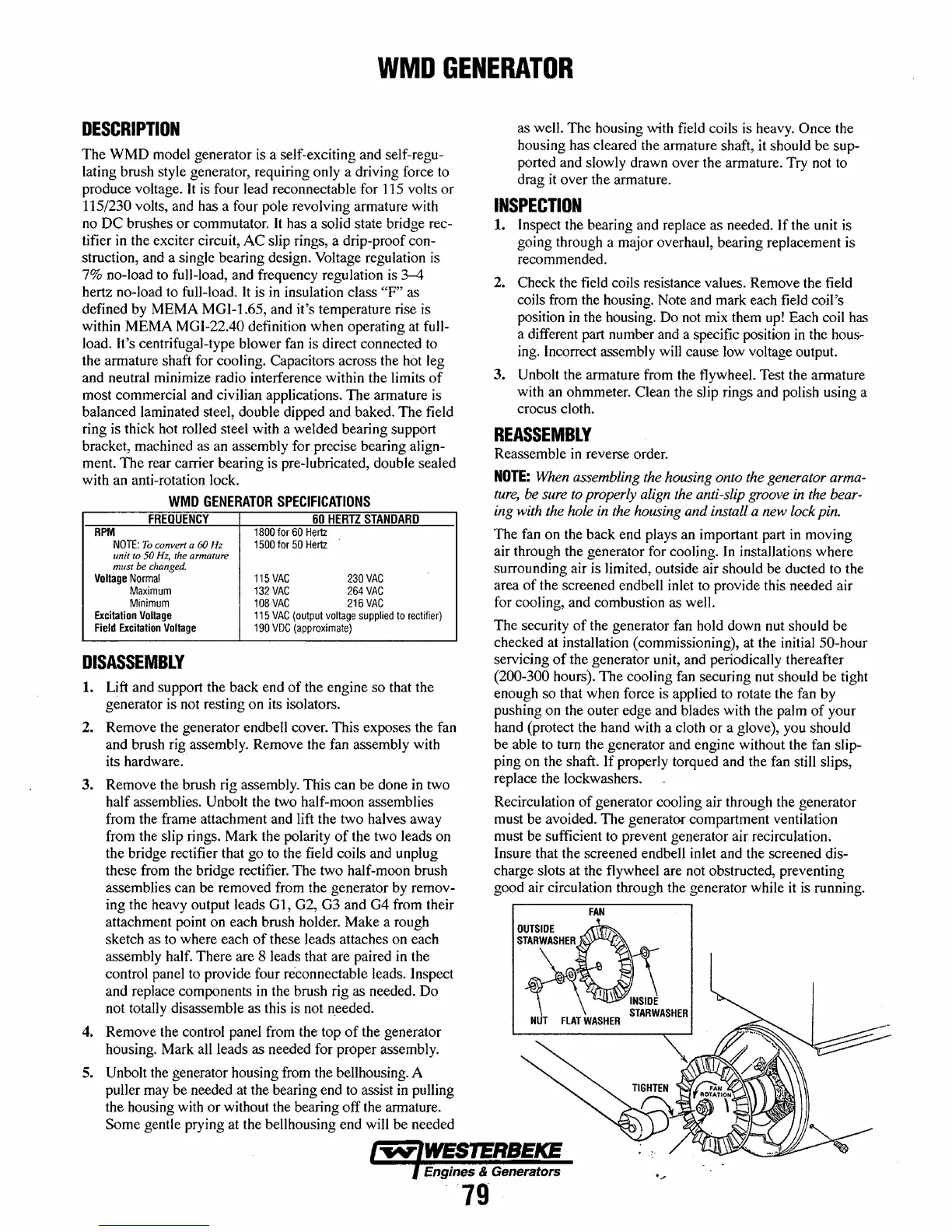

The fan on the back end plays an important part

in

moving

air through the generator for cooling.

In

installations where

surrounding air is limited, outside air should be ducted to the

area

of

the screened endbell inlet to provide this needed air

for cooling, and combustion as well.

The security

of

the generator fan hold down nut should be

checked at installation (commissioning), at the initial

50-hour

servicing

of

the generator unit, and periodically thereafter

(200-300 hours). The cooling fan securing nut should be tight

enough so that when force is applied to rotate the fan by

pushing on the outer edge and blades with the palm

of

your

hand (protect the hand with a cloth

or

a glove), you should

be able to tum the generator and engine without the fan slip-

ping on the shaft.

If

properly torqued and the fan still slips,

replace the lockwashers.

Recirculation

of

generator cooling air through the generator

must be avoided. The generator compartment ventilation

must be sufficient to prevent generator air recirculation.

Insure that the screened endbell inlet and the screened dis-

charge slots at the flywheel are not obstructed, preventing

good air circulation through the generator while

it

is running.

FAN

~~03

NUT

flAT

WASHER

STARWASHER

Engines & Generators

'",

79

Loading...

Loading...