ENGINE

ADJUSTMENTS

TIGHTENING

THE

CYLINDER

HEAD

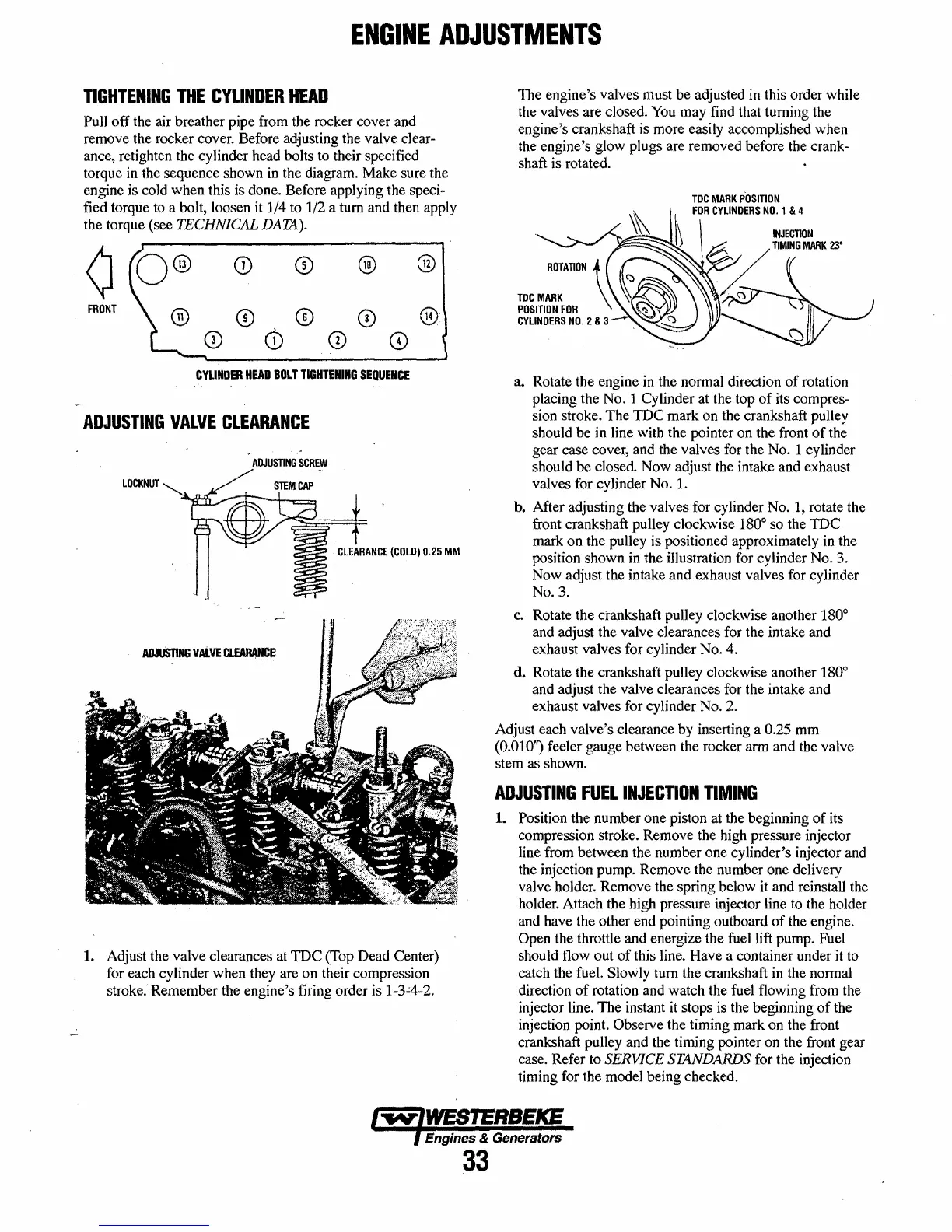

Pull

off

the air breather pipe from the rocker cover and

remove the rocker cover. Before adjusting the valve clear-

ance, retighten the cylinder head bolts to their specified

torque

in

the sequence shown in the diagram. Make sure the

engine is cold when this is done. Before applying the speci-

fied torque

to

a bolt, loosen

it

1/4 to 1/2 a turn and then apply

the torque (see

TECHNICAL

DA1'4.).

¢

CD

CD

®

®

FRONT

CD

CD

CD

®

CD

cb

CD

CD

CYLINDER

HEAD

BOLT

TIGHTENING

SEQUENCE

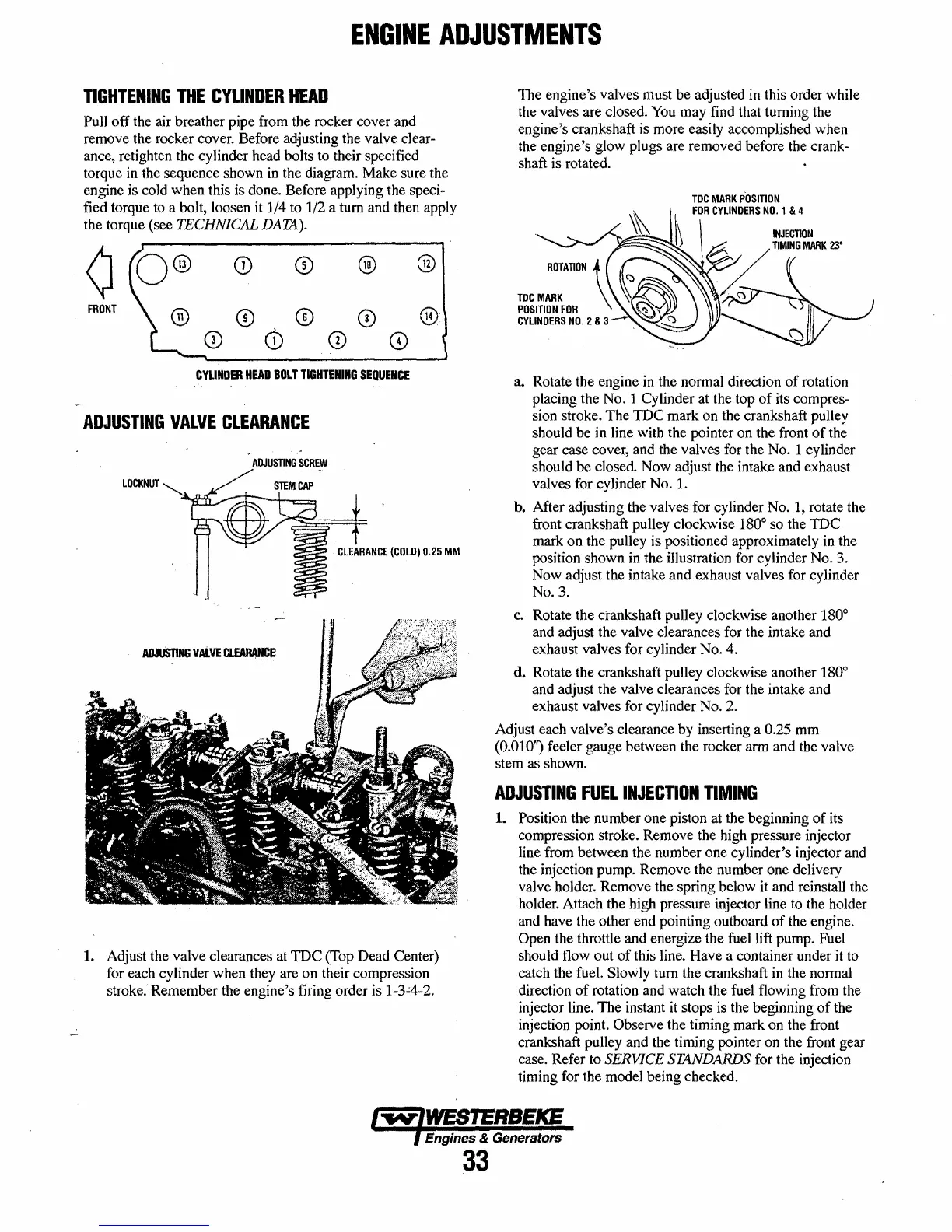

ADJUSTING

VALVE

CLEARANCE

ADJUSTING

SCREW

LOCKNUT

CLEARANCE

(COLD)

0.25

MM

ADJUSTING

VALVE

Cl.EAR4NCE

1.

Adjust the valve clearances at

mc

(Top Dead Center)

for each cylinder when they are on their compression

stroke.' Remember the engine's firing order is 1-3·:4-2.

The engine's valves must be adjusted in this order while

the valves are closed.

You

may find that turning the

engine's crankshaft is more easily accomplished when

the engine's glow plugs are removed before the crank-

shaft is rotated.

a. Rotate the engine in the normal direction

of

rotation

placing the

No.1

Cylinder at the top

of

its compres-

sion stroke. The

mc

mark on the crankshaft pulley

should be in line with the pointer on the front

of

the

gear case cover, and the valves for the

No.1

cylinder

should be closed. Now adjust the intake and exhaust

valves for cylinder

No.1.

h.

After adjusting the valves for cylinder

No.1,

rotate the

front crankshaft pulley clockwise

180

0

so the

IDC

mark on the pulley is positioned approximately in the

position shown

in

the illustration for cylinder

No.3.

Now adjust the intake and exhaust valves for cylinder

No.3.

c.

Rotate the crankshaft pulley clockwise another 180

0

and adjust the valve clearances for the intake and

exhaust valves for cylinder

No.4.

d.

Rotate the crankshaft pulley clockwise another 180

0

and adjust the valve clearances for the intake and

exhaust valves for cylinder

No.2.

Adjust each valve's clearance by inserting a 0.25 mm

(0.010") feeler gauge between the rocker arm and the valve

stem as shown.

ADJUSTING

FUEL

INJECTION

TIMING

1.

Position the number one piston at the beginning

of

its

compression stroke. Remove the high pressure injector

line from between the number one cylinder's injector and

the injection pump. Remove the number one delivery

valve holder. Remove the spring below it and reinstall the

holder. Attach the high pressure injector line to the holder

and have the other end pointing outboard

of

the engine.

Open the throttle and energize the fuel lift pump. Fuel

should flow out

of

this line. Have a container under

it

to

catch the fuel. Slowly turn the crankshaft in the normal

direction

of

rotation and watch the fuel flowing from the

injector line. The instant

it stops is the beginning

of

the

injection point.

Observe the timing mark on the front

crankshaft pulley and the timing pointer on the front gear

case. Refer to

SERVICE STANDARDS for the injection

timing for the model being checked.

Engines & Generators

a3

Loading...

Loading...