ALTERNATOR/REGULATOR

SERVICE

An

alterlUlte

method

for

removing the stator winding, brush

holder

regu/o.tor

unit

and

the

I.e.

diode rectifier assembly

from

the

rear bracket. With the front bracket and rotor

assembly separated from the rear half

of

the alternator:

1.

Insert a

flat~bladed

screwdriver between the stator core

and the edge

of

the rear bracket

on

the same side as the

brush-holder. Raise this side

of

the stator core away from

the bracket so as to open a gap

of

about 1/2 inch.

NOTE:

Be

careful

not

to allow the screwdriver blade to

enter far enough

to touch the stator winding.

2.

Maintaining the 1/2 inch gap, insert the screwdriver

between the stator core and the bracket on the rectifier

side and move the stator laterally toward the

brush· holder

for a distance

of

1/2 to 3/4

of

an

inch without lifting

it

from the bracket.

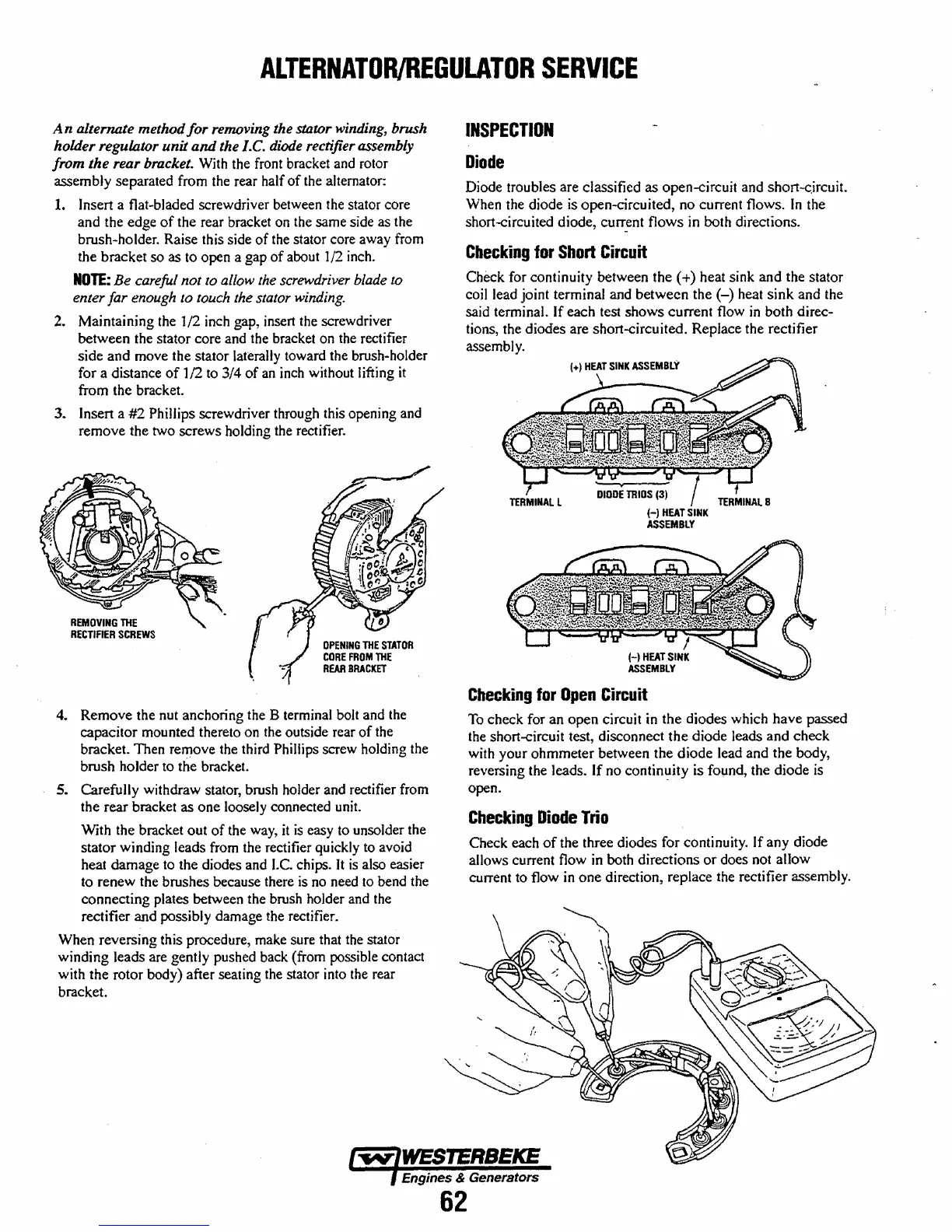

3. Insert a #2 Phillips screwdriver through this opening and

remove the two screws holding the rectifier.

4.

Remove the nut anchoring the B terminal bolt and the

capacitor mounted thereto on the outside rear

of

the

bracket. Then remove the third Phillips screw holding the

brush holder to

the bracket.

5. Carefully withdraw stator, brush holder and rectifier from

the rear bracket as one loosely connected unit.

With the bracket out

of

the way,

it

is

easy to unsolder the

stator winding leads from the rectifier quickly

to

avoid

heat damage to the diodes and

I.C

chips. It

is

also easier

to renew the brushes because there is

no

need

to

bend the

connecting plates between the brush holder and the

rectifier and possibly damage the rectifier.

When reversing this procedure, make sure that the stator

winding leads are gently pushed back (from possible contact

with the rotor body) after seating the stator into the rear

bracket.

INSPECTION

Diode

Diode troubles are classified as open-circuit and

short~c.ircuit.

When the diode is open-circuited, no current flows.

In

the

short-circuited diode,

curr_ent

flows

in

both directions.

Checking

for

Short

Circuit

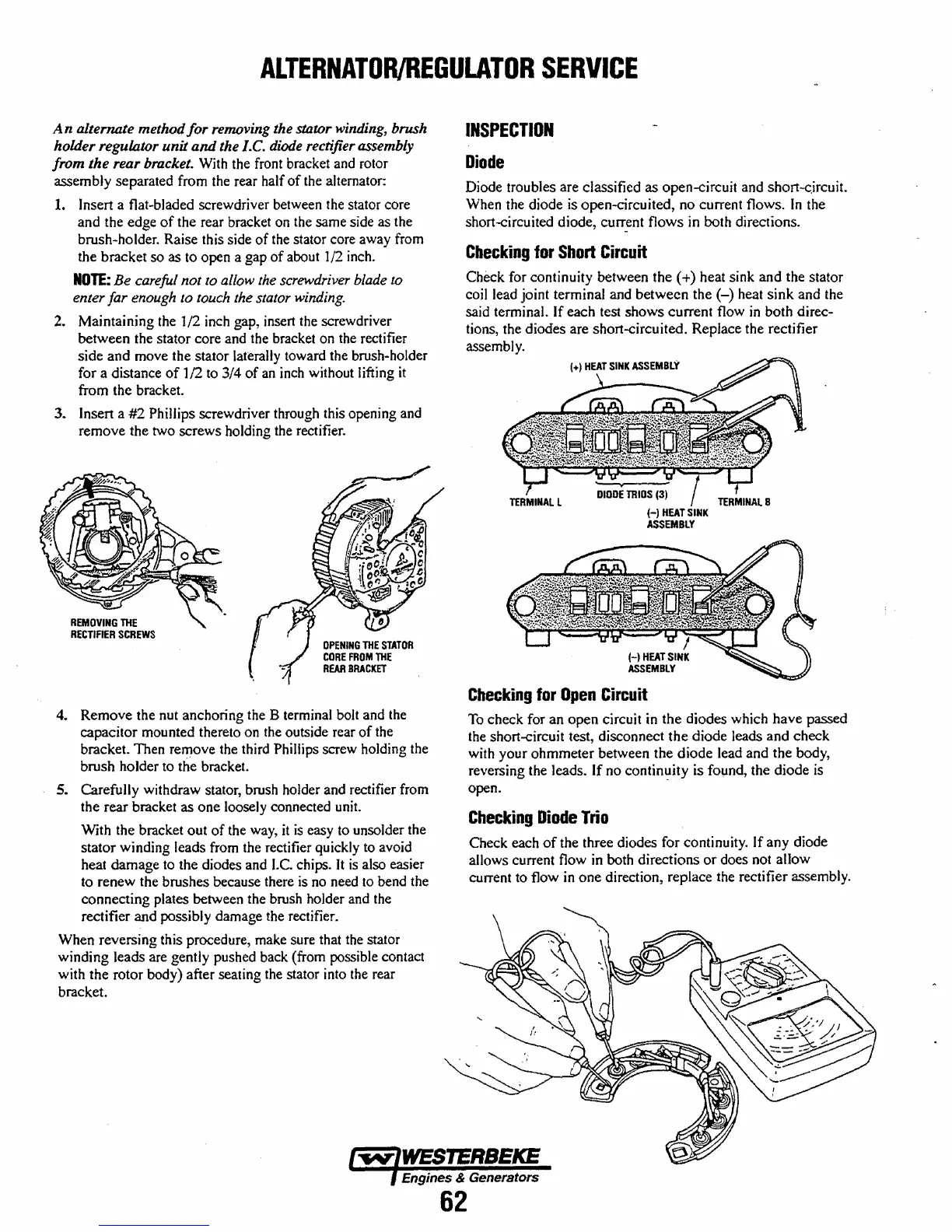

Check for continuity between the (+) heat sink and the stator

cojl lead joint terminal and betwecn the

(-)

heat sink and the

said

terminal. If each test shows current flow

in

both direc-

tions, the diodes are short-circuited. Replace the rectifier

assembly.

.

DIODE

TRIOS

(3)

HHEATSINK

ASSEMBLY

Checking

for

Open

Circuit

To

check for an open circuit

in

the diodes which have passed

the

short-circ.uit test, disconnect the diode leads and check

with your ohmmeter between the diode lead and the body,

reversing the leads.

If

no continllity is found, the diode

is

open.

Checking

Diode

Trio

Check each

of

the three diodes for continuity. If any diode

allows current flow in both directions

or

does not allow

current to flow

in

one direction, replace the rectifier assembly.

Engines & Generators

62

Loading...

Loading...