3.6Minimizing Positioning Time

123

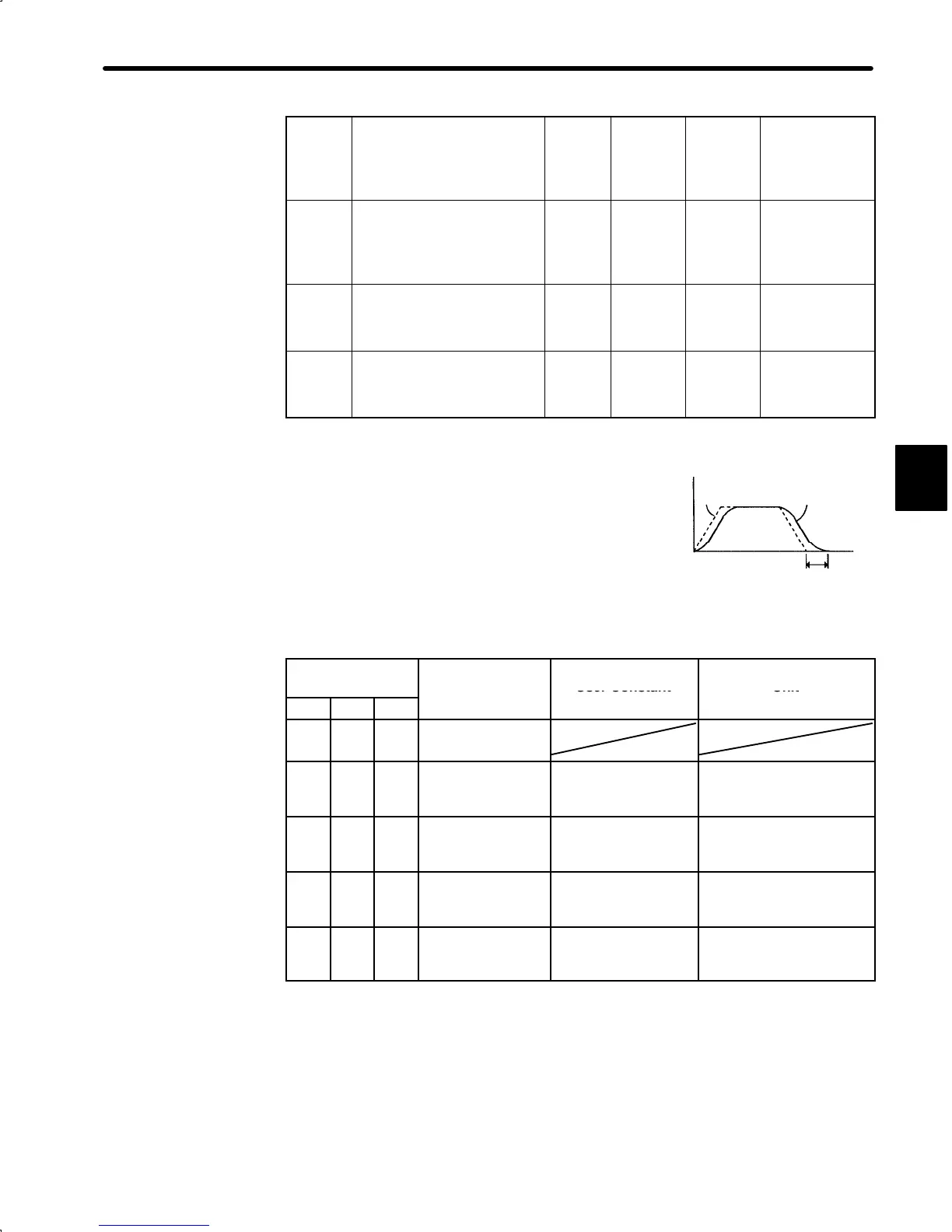

Cn-0C

TRQMSW Mode Switch

(Torque

Reference)

Unit: % Setting

Range: 0

to

Maximum

Torque

Factory

Setting:

200

For

Speed/Torque

Control and

Position Control

Cn-0D

REFMSW Mode Switch

(Speed

Reference)

Unit:

r/min

Setting

Range: 0

to

Maximum

Speed

Factory

Setting: 0

For

Speed/Torque

Control and

Position Control

Cn-0E

ACCMSW Mode Switch

(Acceleration

Reference)

Unit: 10

(r/min)/s

Setting

Range: 0

to 3000

Factory

Setting: 0

For

Speed/Torque

Control and

Position Control

Cn-0F

ERPMSW Mode Switch

(Error Pulse)

Unit:

Refer-

ence

Unit

Setting

Range: 0

to 10000

Factory

Setting:

10000

For Position

Control Only

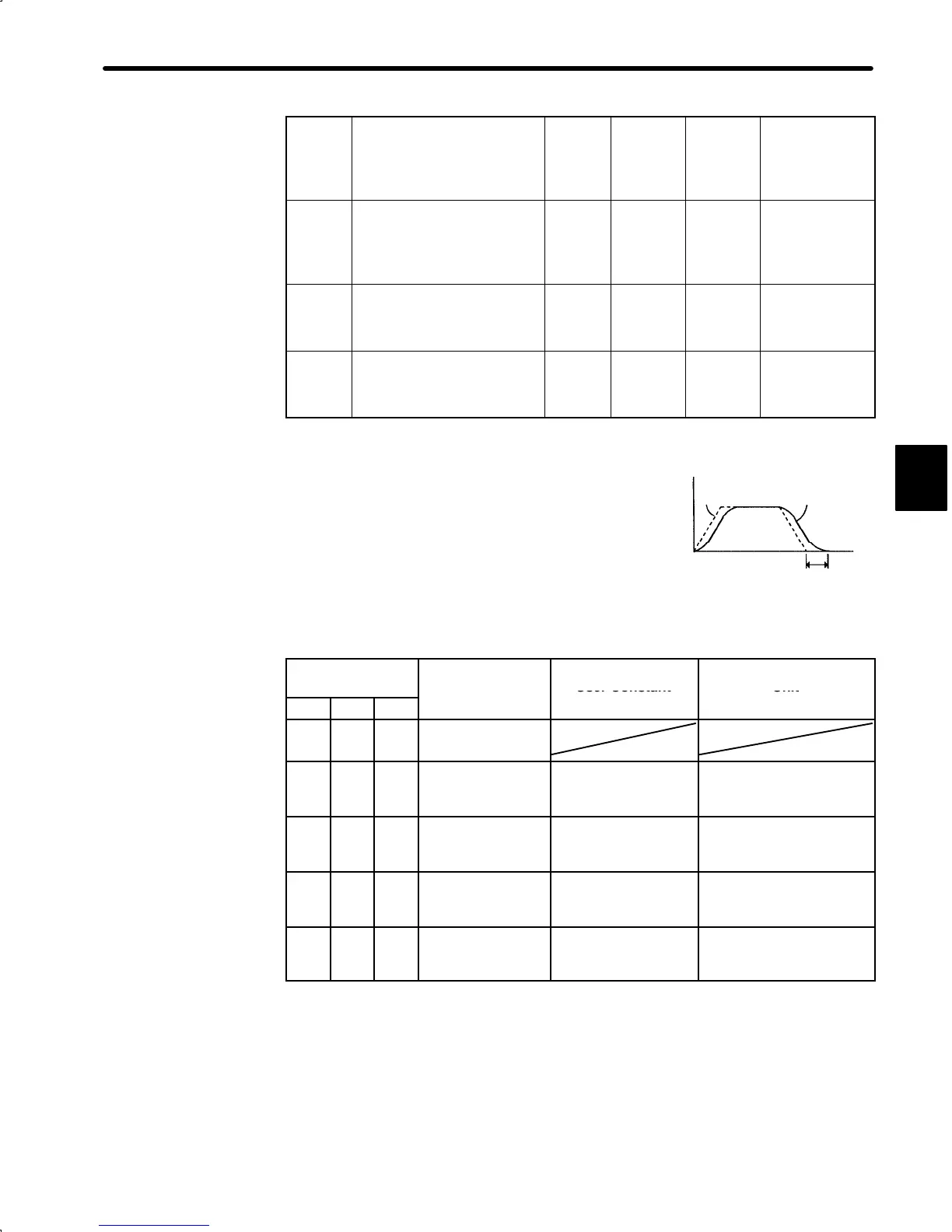

Mode switch is used to reduce settling time and

suppress undershoot when the motor stops. It

switches PI control to P control when certain

conditions are met.

The Servopack allows use of four different types of mode switch. To select a mode switch,

set bits B, C and D of memory switch Cn-01.

Memory Switch

Cn-01

Mode Switch Set-

User Constant Unit

Bit D Bit C Bit B

ng

− − 1

Does not use

mode switch.

0 0 0

Uses torque refer-

ence as a detec-

tion point.

Cn-0C

Percentage of rated

torque: %

0 1 0

Uses speed refer-

ence as a detec-

tion point.

Cn-0D Motor speed: r/min

1 0 0

Uses acceleration

reference as a

detection point.

Cn-0E

Acceleration reference in-

side the SGD Servopack:

10 (r/min)/s

1 1 0

Uses error pulse

as a detection

point.

Cn-0F Reference unit

User constant Cn-0F is for position control (SGDA-jjjP) only. For speed/torque con-

trol (SGDA-jjjS), Cn-0F is used to set a zero-clamp level.

3

Speed

Reference

Actual motor

operation

Time

Settling time

Loading...

Loading...