INSPECTION, MAINTENANCE AND TROUBLESHOOTING

6.1.1 Servomotor

344

6.1 Inspection and Maintenance

This section describes the basic inspections and maintenance for Σ-Series servo drives.

6.1.1 Servomotor 344.....................................................

6.1.2 Servopack 345......................................................

6.1.3 Replacing Battery for Absolute Encoder 346............................

6.1.1 Servomotor

For inspection and maintenance of servomotors, follow the simple, daily inspection proce-

dures in the table below.

The AC servomotors are brushless. Simple, daily inspection is sufficient. The inspection and

maintenance frequencies in the table are only guidelines. Increase or decrease the frequen-

cy to suit the operating conditions and environment.

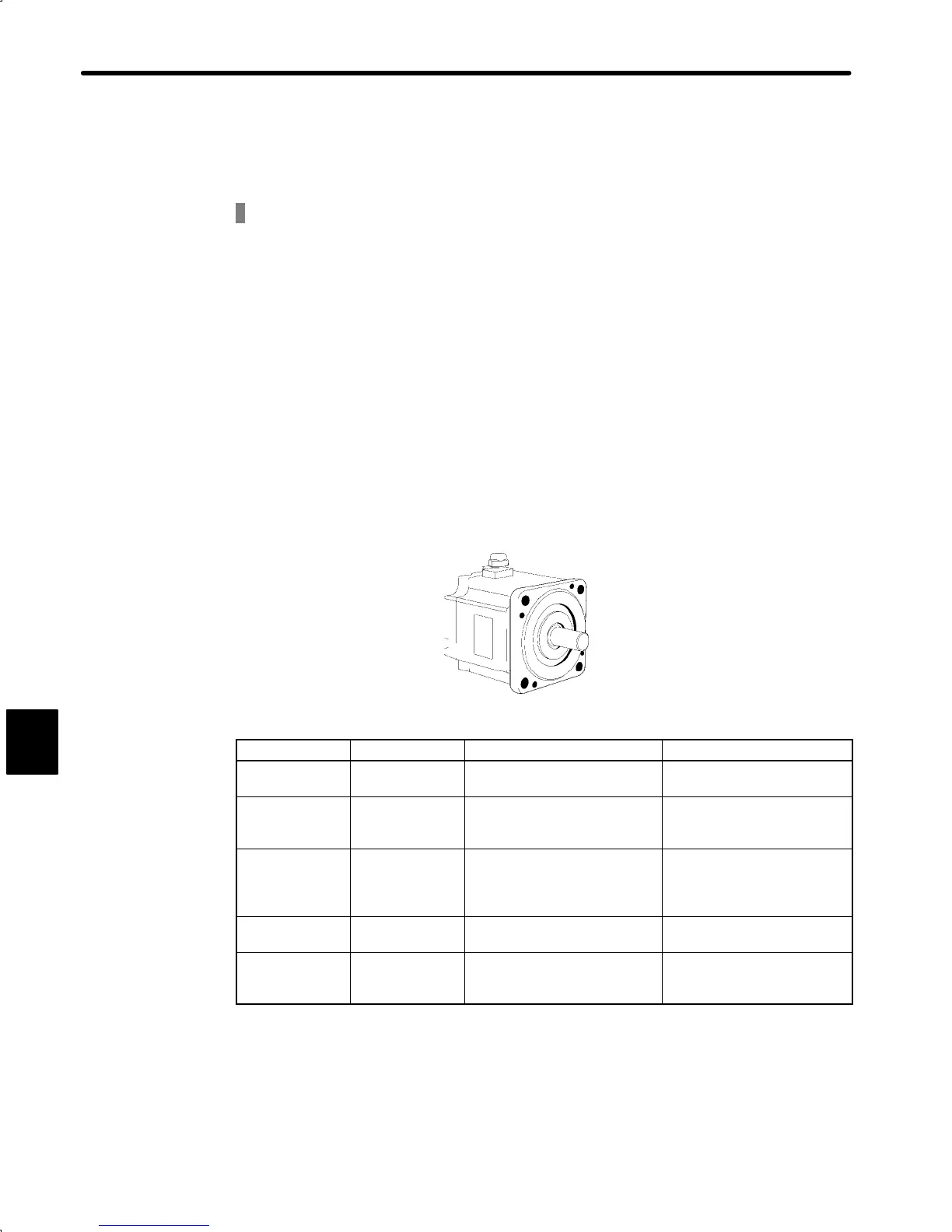

Item Frequency Procedure Comments

Vibration and

noise

Daily Touch and listen. Levels higher than normal?

Appearance According to

degree of

contamination

Clean with cloth or

compressed air.

Insulation

resistance

measurement

Yearly Disconnect Servopack and

test insulation resistance at

500 V. Must exceed 10 MΩ.

(See note below)

Contact your Yaskawa

representative if the

insulation resistance is

below 10 M

Ω

.

Replace oil seal Every 5,000

hours

Remove servomotor from

machine and replace oil seal.

Applies only to motors with

oil seal.

Overhaul Every 20,000

hours or 5 years

Contact your Yaskawa

representative.

The customer should not

disassemble and clean the

servomotor.

Note Measure across the servomotor FG (green/yellow) and the U-phase (red), V-

phase (white), or W-phase (blue) power lead.

During inspection and maintenance, do not disassemble the servomotor.

If disassembly of the servomotor is required, contact your Yaskawa representative.

6

Loading...

Loading...