5.1 Selecting aΣ -Series Servo

211

3) Machine Data Table

Fill out the machine data table below as an aid to selecting the drive system. When the

machine data table is complete, use the servomotor sizing software to select the motor

capacity.

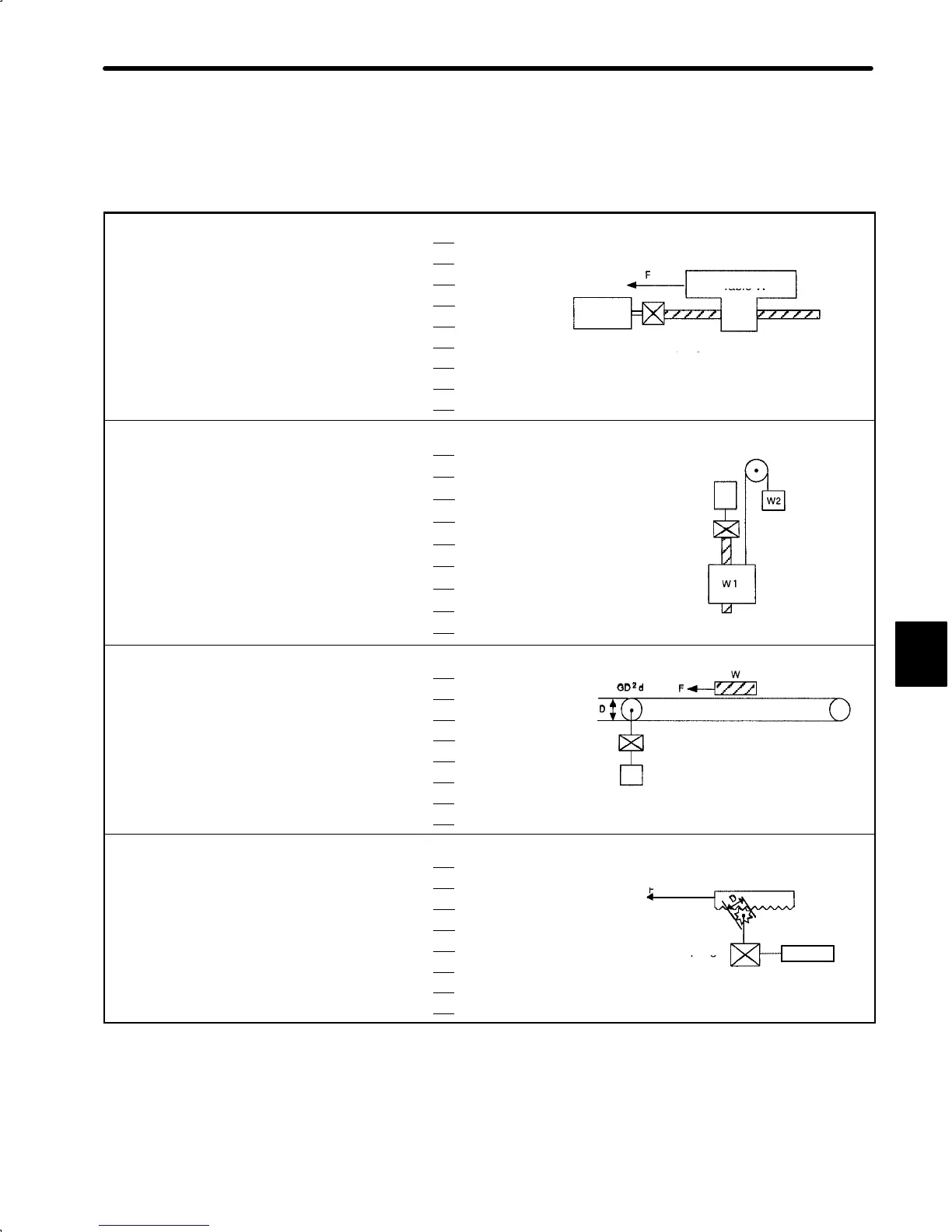

1) Ball Screw Horizontal Axis

Load mass W kg (lb)

Thrust F kg (lb)

Coefficient of friction

µ

Table W

Overall efficiency

η

Gear ratio R (= Nm/Nl)

Motor

Ball screw

Gear+coupling GD

2

g

kg¡cm

2

(lb¡in

2

.)

Gear+coupling

Ball screw pitch P mm (in.)

GD

2

g

Ball screw diameter D mm (in.)

Ball screw length L mm (in.)

2) Ball Screw Vertical Axis

Load mass W

1

kg (lb)

Counterweight W

2

kg (lb)

Coefficient of friction

µ

Motor

Overall efficiency

η

Gear ratio R (= Nm/Nl)

GD

2

g

Gear+coupling GD

2

g

kg¡cm

2

(lb¡in

2

.)

Ball screw pitch P mm (in.)

Ball screw diameter D mm (in.)

Ball screw length L mm (in.)

Ball screw

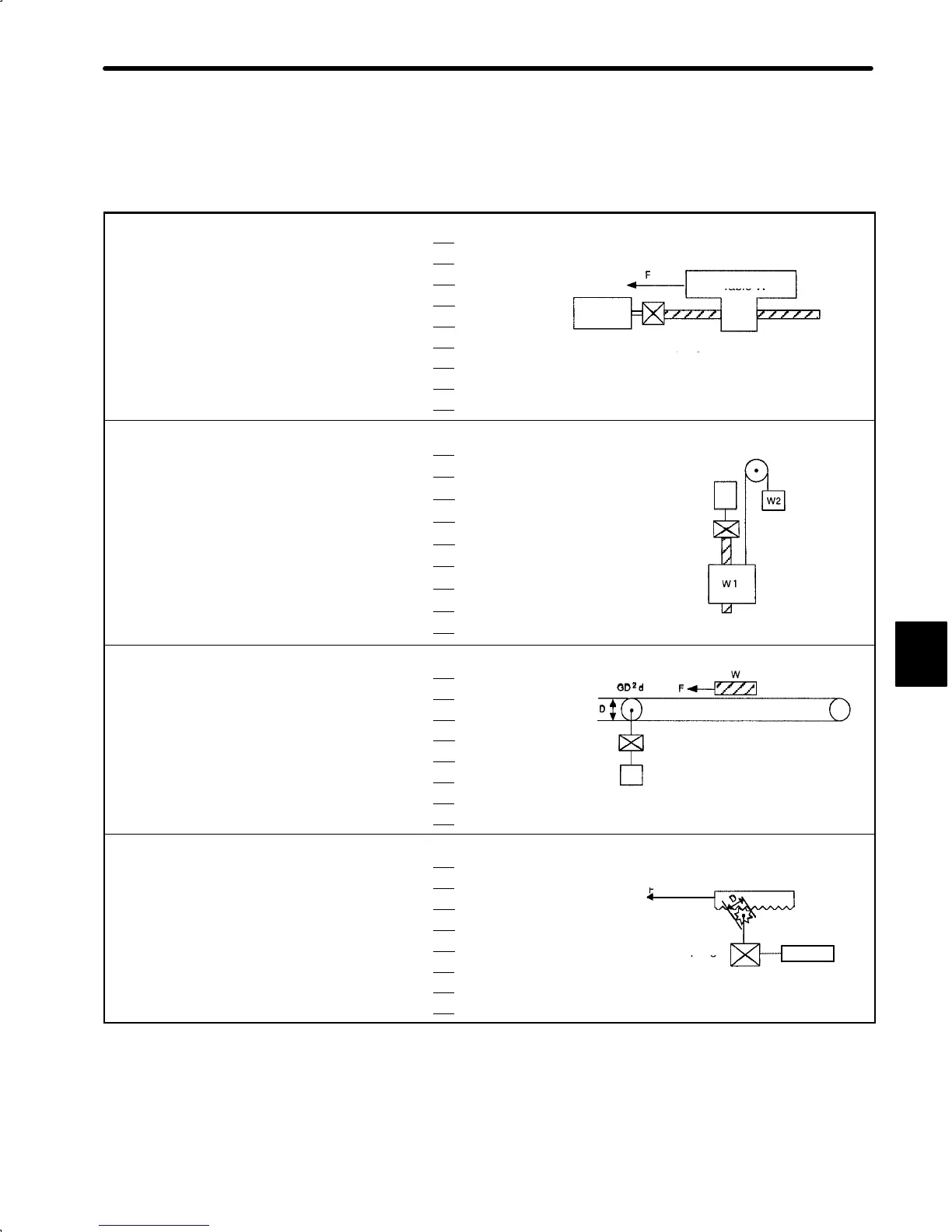

3) Timing Belt

Load mass W kg (lb)

Pulley

Thrust F kg (lb)

Coefficient of friction

µ

Overall efficiency

η

Gear+couplin

Timing belt

Gear ratio R (= Nm/Nl)

GD

2

g

Gear+coupling GD

2

g

kg¡cm

2

(lb¡in

2

.)

Pulley GD

2

d

kg¡cm

2

(lb¡in

2

.)

Motor

Pulley diameter D mm (in.)

4) Rack and Pinion

Load mass W kg (lb)

Thrust F kg (lb)

W

Coefficient of friction

µ

Rack

Overall efficiency

η

Pinion

Gear ratio R (= Nm/Nl)

Gear+coupling

Motor

Gear+coupling GD

2

g

kg¡cm

2

(lb¡in

2

.)

GD

2

g

Pinion diameter D mm (in.)

Pinion thickness t mm (in.)

5

Loading...

Loading...