SERVO SELECTION AND DATA SHEETS

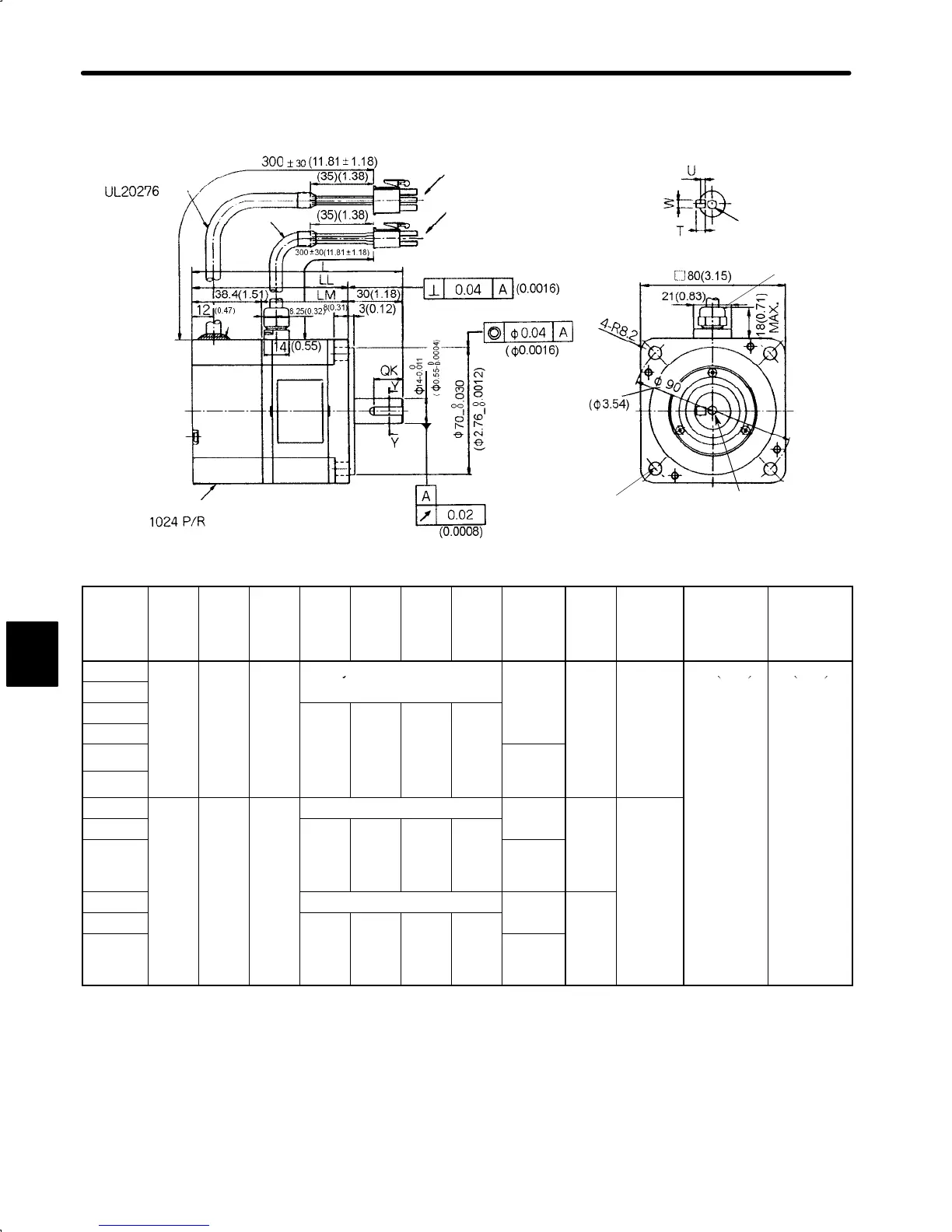

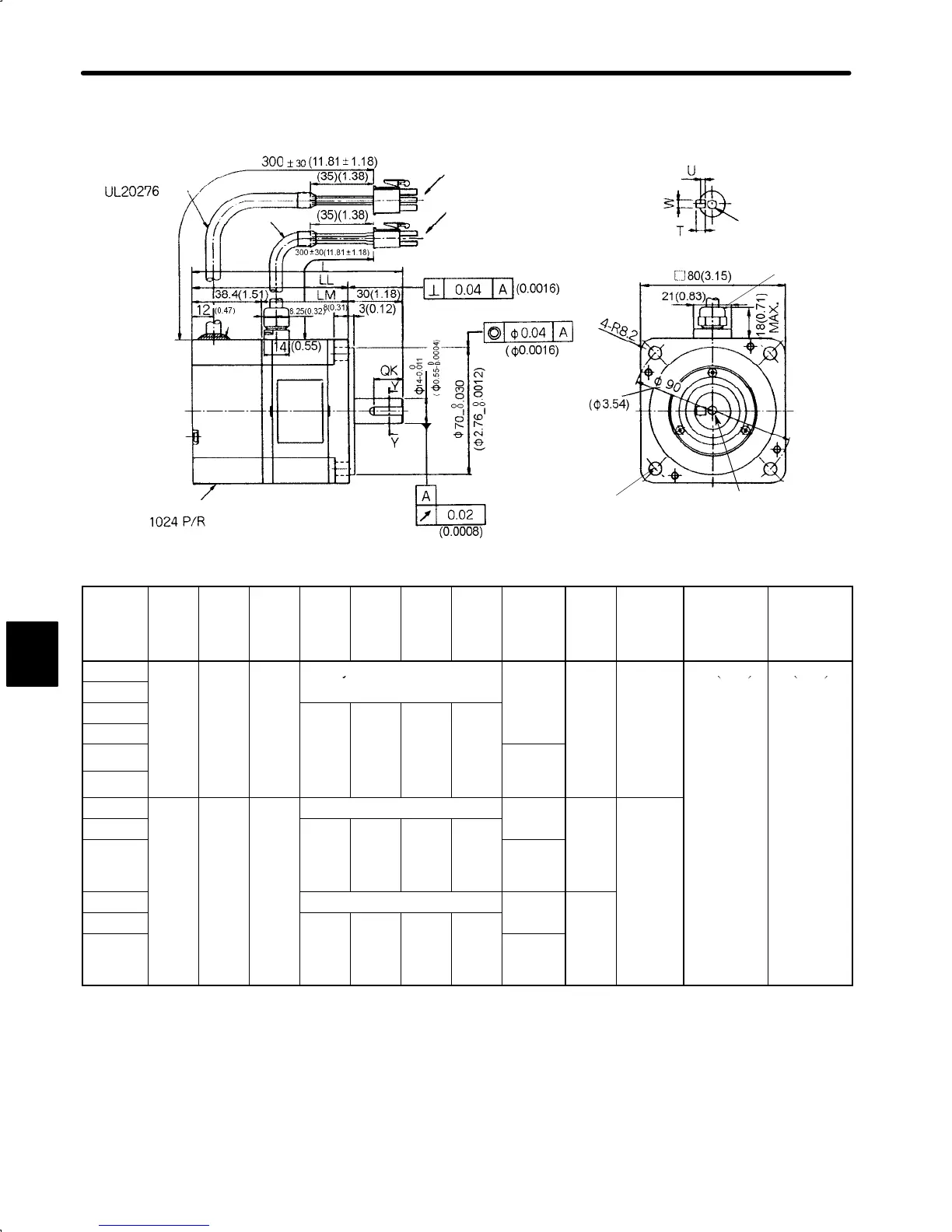

5.4.1 Servomotor Dimensional Drawings

280

• 200 W (0.27 HP), 300 W (0.40 HP) (100 V only), 400 W (0.53HP) (200 V only)

Encoder Lead

Encoder Plug

Motor Plug

Absolute encoder

Cross-section Y-Y

Screw

Hex. nut 14

(0.55)

4-∅7

(4-∅0.28)

MTG Holes

Screw

Shaft end screw hole

(SGMP-jj

A(B)W16, with key

type only)

Type

SGMP-

L LL LM QK U W T Screw

dimen-

sions

Out-

put

W

(HP)

Approx.

mass

kg

(lb)

Allowable

radial load

N (lb)

Allowable

thrust

load N (lb)

02AW12

116.5

86.5

48.1

No key --- 200

1.6

245 (55.1) 68 (15.4)

02BW12

(4.59) (3.41) (1.89)

(0.27) (3.53)

02AW14

16

3

5

5

02BW14

(0.63) (0.12) (0.20) (0.20)

02AW16

M5,

02BW16

ep

(0.31)

03BW12

136.5

106.5

68.1

No key

--- 300

2.3

03BW14

(5.37) (4.19) (2.68)

16

3

5

5

(0.40) (5.07)

03BW16

(0.63) (0.12) (0.20) (0.20)

M5,

depth 8

(0.31)

04AW12 No key

--- 400

04AW14

16

3

5

5

(0.53)

04AW16

(0.63) (0.12) (0.20) (0.20)

M5,

depth 8

(0.31)

Note 1) The detector uses a 12-bit absolute encoder 1024 P/R.

2) Type “A” indicates 200 V specification, and type “B” indicates 100 V specification.

3) “02A(B)W14”, “02A(B)W16”,” 03BW14”, “03BW16”,” 04AW14”, and “04AW16” have a

keyed shaft. The keyway complies with JIS B 1301-1976 (precision). A straight key is

supplied.

5

cont.

Loading...

Loading...