APPLICATIONS OF Σ-SERIES PRODUCTS

3.2.5 Using Electronic Gearcont.

82

3) Examples of Setting an Electronic Gear Ratio for Different Load Mechanisms

Ball Screw

Reference unit: 0.001 mm

Load shaft

Incremental

encoder:

Ball screw

pitch: 6 mm

Travel distance per

revolution of load shaft

Electronic gear ratio

Preset

values

Cn-24

Cn-25

B

A

=

2048 × 4 × 1

6000 × 1

=

Cn-24

Cn-25

=

6mm

0.001mm

= 6000

8192

6000

2048 pulses per revolution

Disc Table

Reference unit:

0.1°

Gear ratio:

3:1

Load shaft

Incremental encoder:

2048 pulses per revolution

Travel distance per

revolution of load shaft

Preset

values

24576

3600

Cn-24

Cn-25

0.1°

360°

=

= 3600

Electronic gear ratio

B

A

=

2048 × 4 × 3

3600 × 1

=

Cn-24

Cn-25

Belt & Pulley

Pulley diameter:

100 mm

Absolute encoder:

1024 pulses per revolution

Cn-24

Cn-25

Load shaft

Reference unit: 0.0254 mm

Gear ratio:

2.4 : 1

Travel distance per

revolution of load shaft

=

3.14 x 100mm

0.0254mm

= 12362

Electronic gear ratio

B

A

=

1024 × 4 × 2.4

12362 × 1

=

Cn-24

Cn-25

49152

61810

=

9830.4

12362

=

49152

61810

Preset

values

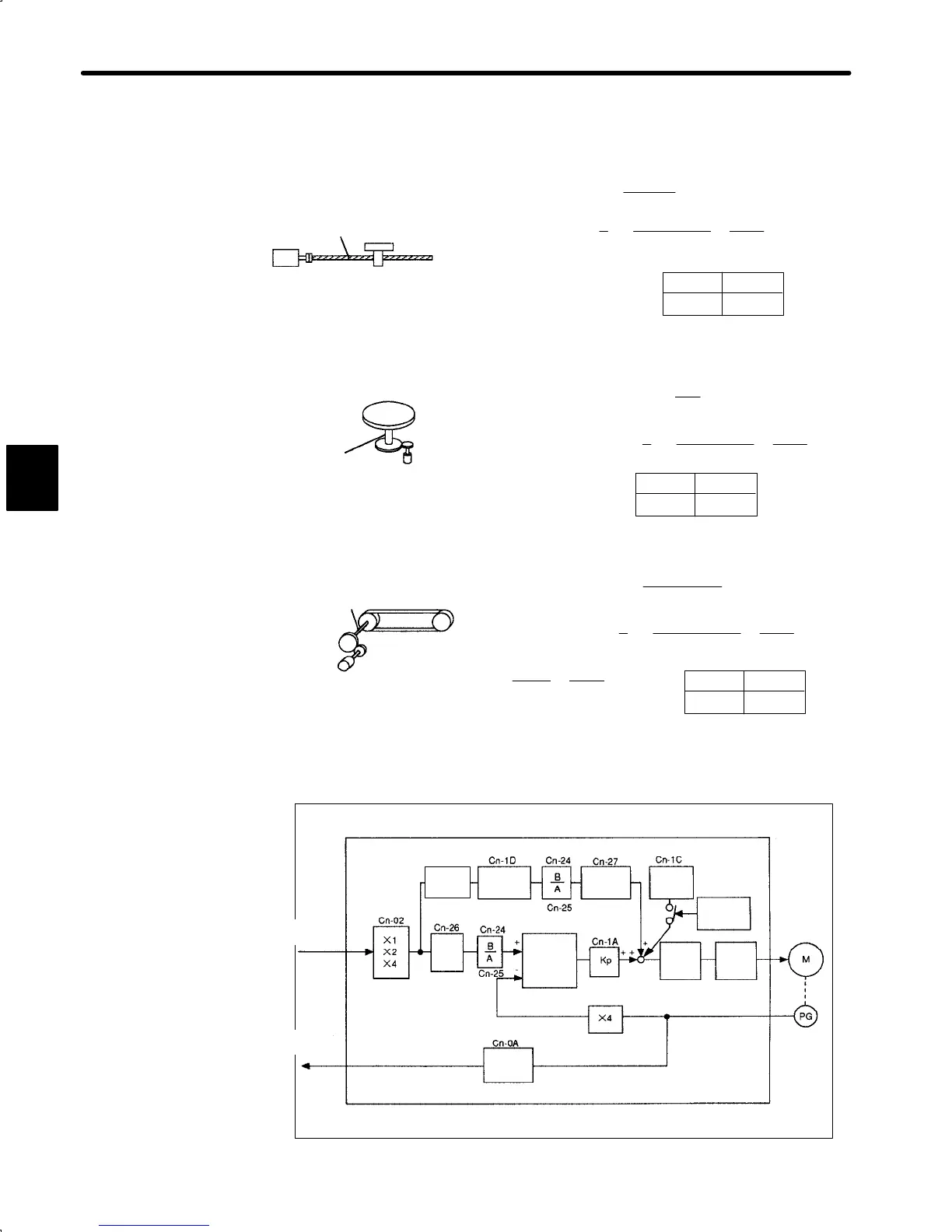

4) Control Block Diagram for SGDA-jjjP Servopack for Position Control

SGDA Servopack for position control

Feed-forw

ard gain

Primary

lag filter

Bias

COIN

signal

Speed

loop

Current

loop

SGM

Servomotor

Encoder

Error

counter

Frequency

dividing

Smoot

hing

Differ-

entiation

Reference

pulse

PG signal

output

3

Loading...

Loading...