3D Systems, Inc.

71

TROUBLESHOOTING

Below is a brief outline of some simple troubleshooting procedures for the ProX 800. For electrical diagrams, see the following

placard illustrations which are also physically located on the machine:

• “Power Panel Connections Placard” on page 63

• “Power Panel Layout Placard” on page 73

• “Electrical Block Diagram Placard” on page 74

• “Chamber Controller Placard” on page 75

POWER OUTAGES

If you are present when a power outage occurs, or if you discover that the main power is off, switch the main power disconnect

off (see “Master Power Shut-off” on page 8) which is located on the right side of the machine.

ProX 800 PRINTER SHUTDOWN

If you do not plan on operating the system on a regular basis and want to shut it down for an extended period of time, power

off the UI and turn off the main power disconnect. See “Master Power Shut-off” on page 8.

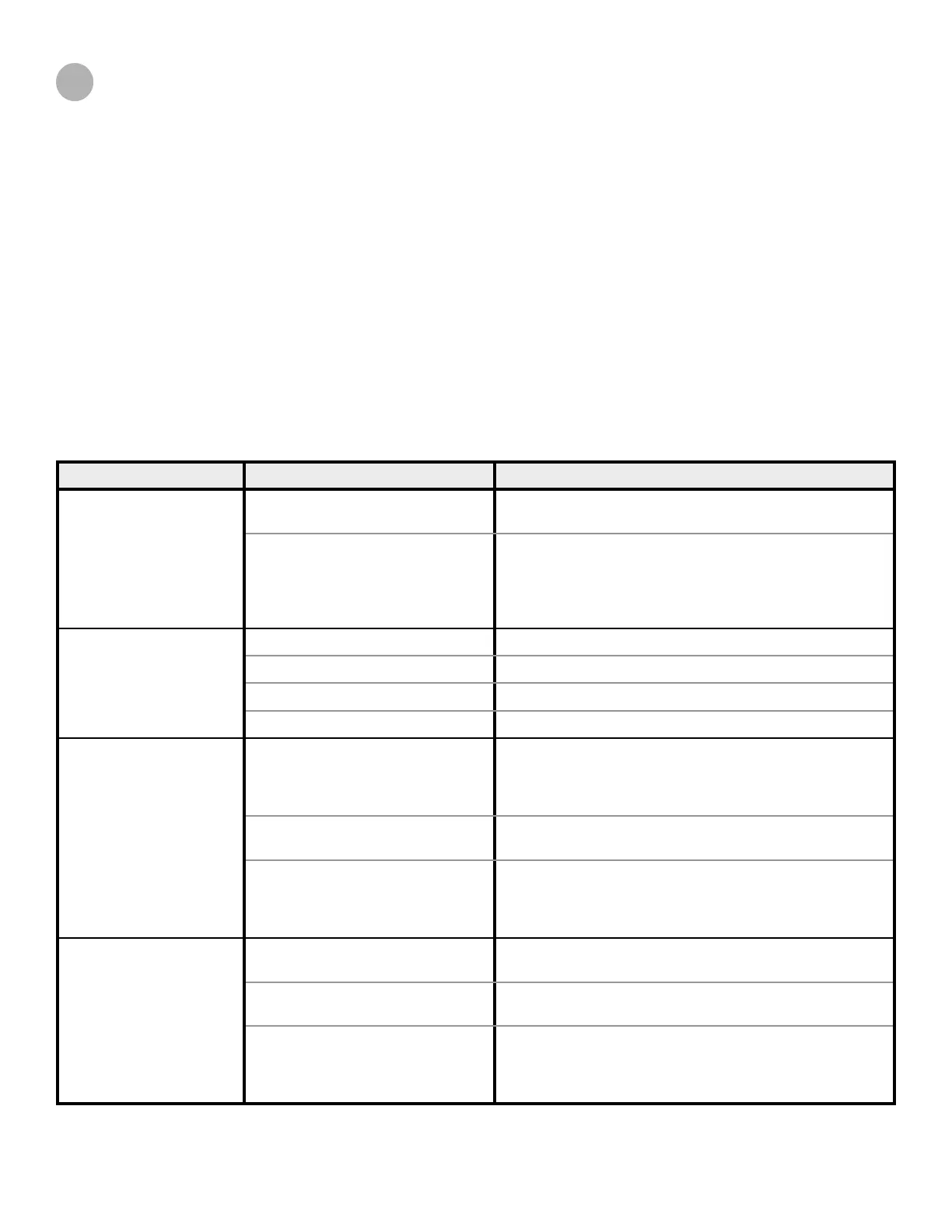

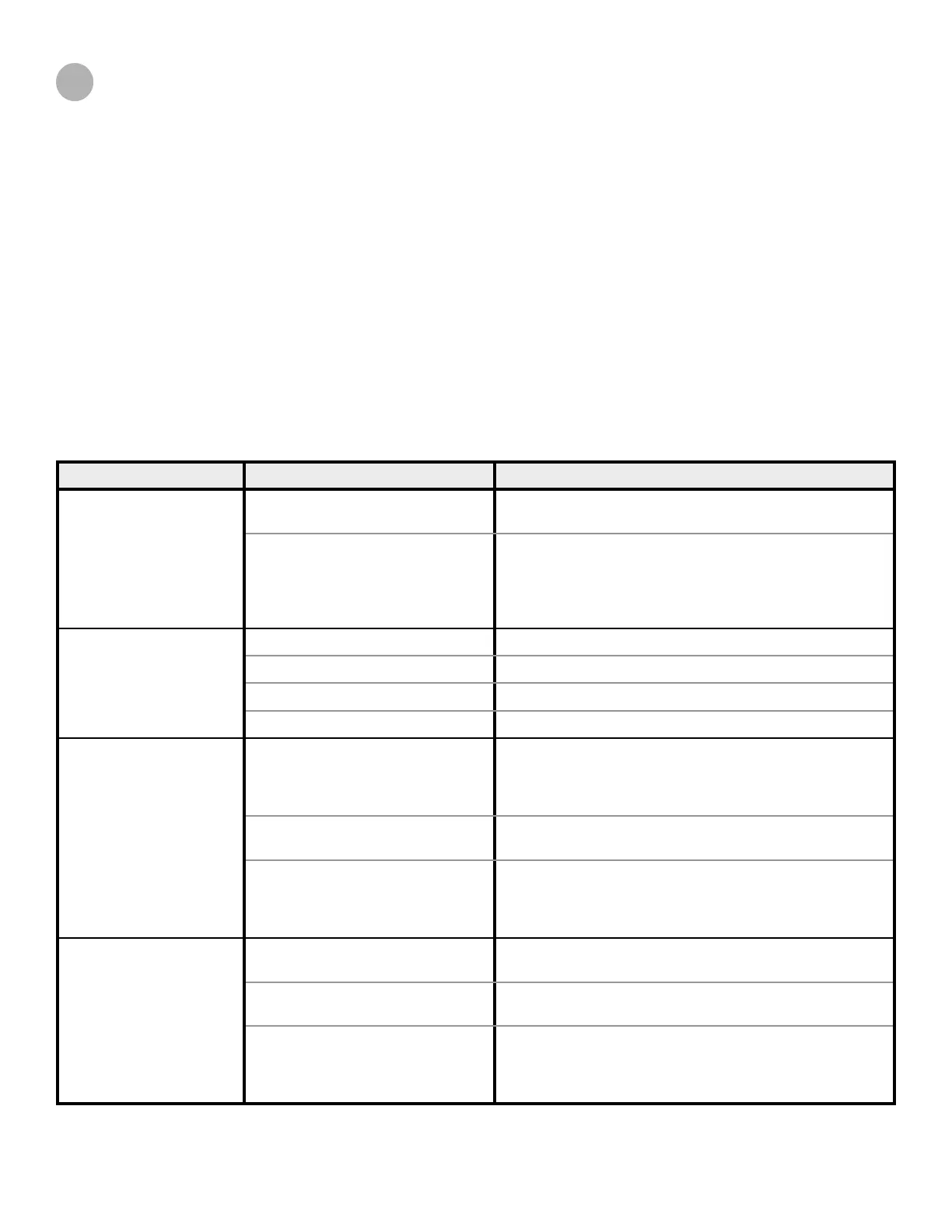

ERROR SYMPTOMS AND OTHER PROBLEMS

SYMPTOM CAUSE ACTION

Printer does not operate. Breaker on DC power supply is

tripped.

Reset breaker. Refer to the “Power Panel Layout Placard”

on page 73

Loose cables or poor electrical

connections.

Check the plugs and cables to ensure that they are tightly

connected and that the electrical outlet is working.

Verify that the unit power switches are ON. Refer to the

“Electrical Block Diagram Placard” on page 74 for

connector locations.

Entire system does not

power up

An E-Stop is depressed. Reset the E-Stop(s) and press system enable.

Main power plug is not engaged. Plug cord into the wall outlet.

No power is coming from the wall. Reset circuit breaker for the wall outlet.

The circuit breaker is tripped. Reset circuit breaker in the back of the machine.

Printhead (IPM) does not

operate.

The laser is not turned on. Turn the laser power supply key to the ON position. Verify

that the switch on the laser power supply is ON. Turn on

the laser. Refer to the illustration in “Printhead Overview”

on page 23 for the location of this.

Laser interlock not satised. Read error shown on laser power supply. Call “Customer

Support Hotline” on page 76.

3D equipment interlock safety relay

not satised, system will not enable.

Satisfy all safety interlocks or the laser will not operate. If

interlocks cannot be satised, and the system cannot be

enabled after pressing the System Enable button, contact

“Customer Support Hotline” on page 76.

Elevator, leveler, or

applicator does not move.

Loose cables. Secure all connections. Refer to the “Electrical Block Dia-

gram Placard” on page 74 for connector locations.

Interlocks not satised. Check that interlocks are satised and that the system is

enabled.

Bad circuit board or motor driver. Try to move using the Print3D Pro touchscreen application.

If no motion is possible, press Restart on the Tools Menu

Screen to restart the system. Otherwise, contact “Custom-

er Support Hotline” on page 76.

15

Loading...

Loading...