3D Systems, Inc.

49

MATERIAL DELIVERY MODULE (MDM) INSTALLATION

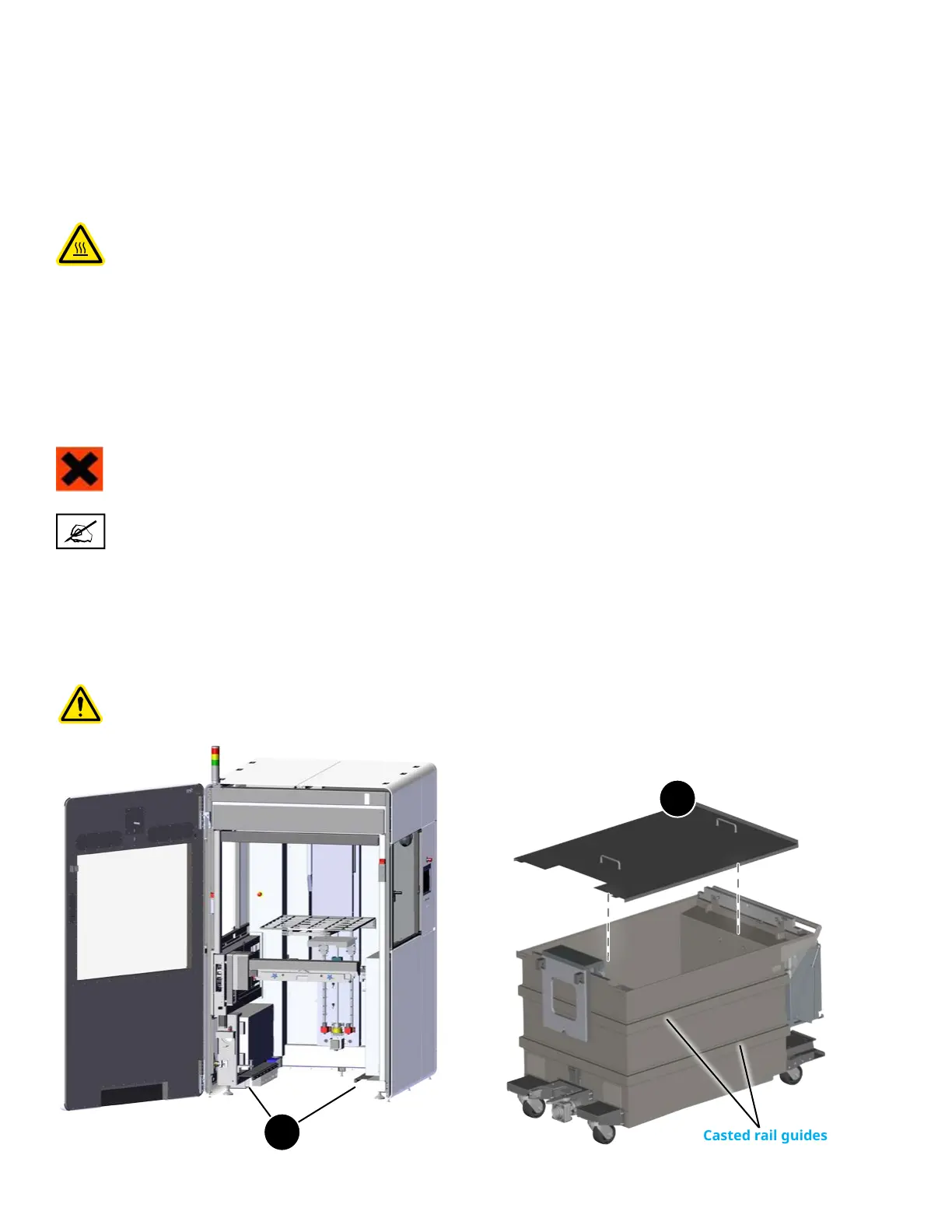

The MDM has two casted rail guides on each of its sides for guiding it into the print chamber. See the illustration below.

HOT SURFACE: The area underneath the MDM where the heaters are located is hot (about 40°C (104°F)) —Do not

reach underneath!

Perform the following operations prior to removing the MDM:

1. Home the print applicator by navigating to Tools > Print Applicator and pressing Move to Home.

2. Home the elevator by navigating to Tools > Elevator/Leveler and pressing Move to Home.

3. On the Tools > Elevator/Leveler screen, press the edit button for Move Distance, then type in 10 and a minus sign (-) and

press Set. Press the Move Distance button to move the elevator down 10”.

You must also ensure that the print applicator is in its storage location on the MDM. See the section “Print Applicator

Installation and Removal” on page 48 for instructions. Assuming the MDM is outside the printer, the following steps describe

how to install it.

Clear connecting cables

Remove MDM lid

Casted rail guides

IRRITANT: While performing this procedure, wear protective clothing, disposable nitrile gloves, and goggles.

NOTE: Move the MDM very slowly. Sudden starts and stops can create waves in the material and result in

material spills, even with the MDM lid in place. Continuous slow movement is critical to preventing any

movement of the printer with the heavy MDM. Any change in the printer’s inner frame placement will require

recalibration by a trained service technician.

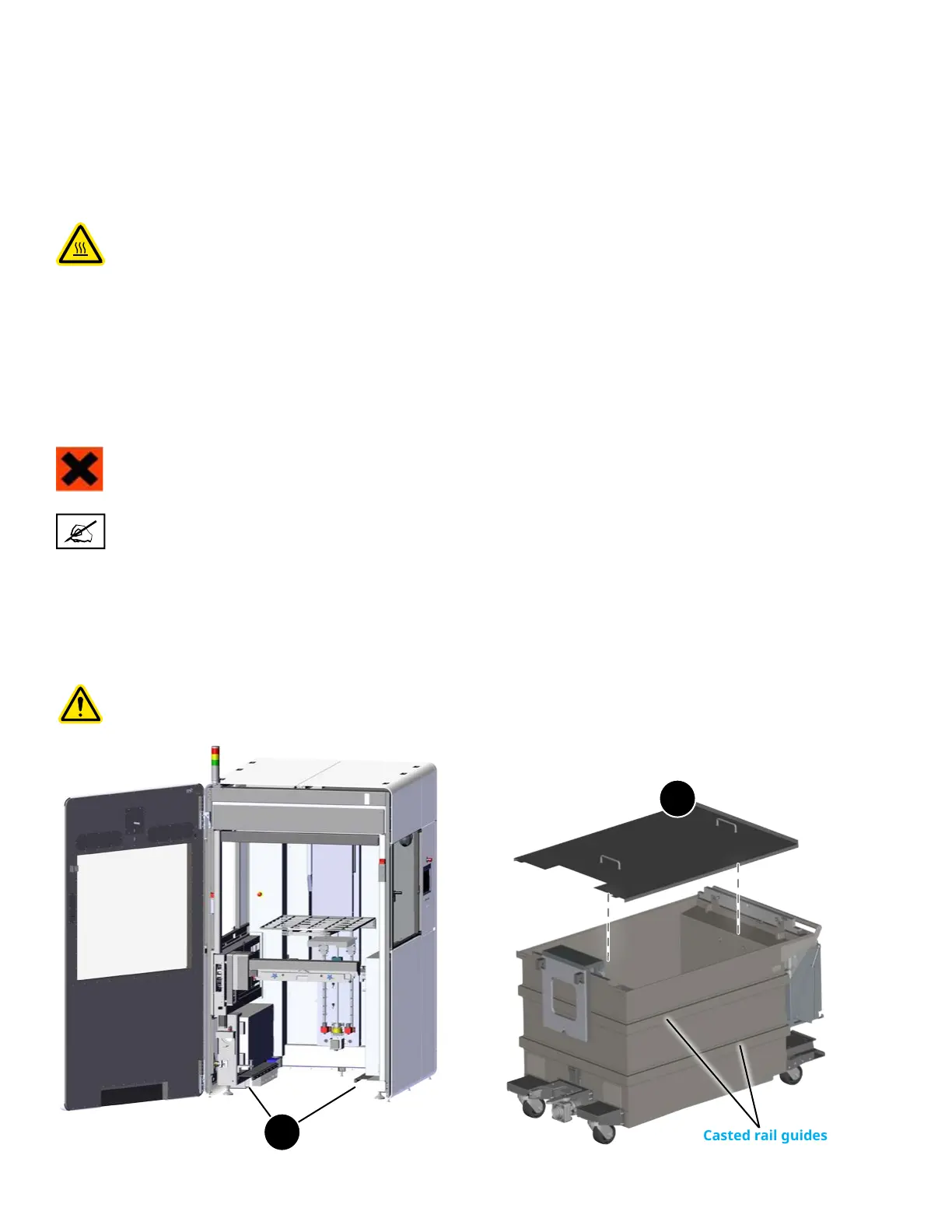

1. Open the front door of the ProX 800. Make sure that the connecting cables are out of the way before you attempt to place

the MDM into the machine (1).

2. Wearing nitrile gloves, remove the cover from the MDM (2). Wipe off any excess material on the inside of the lid using a

towel soaked with isopropyl alcohol. When nished, store the lid in a safe place.

CAUTION: Ensure no alcohol is spilled into the MDM. This will contaminate the material.

1

2

PRINT APPLICATOR CLEANING

The print applicator will need to be cleaned periodically. Remove the print applicator and wipe it off using a paper towel soaked

with isopropyl alcohol. Be careful not to contaminate the material in the MDM with the isopropyl alcohol. Be sure to wear nitrile

gloves when handling the print applicator. Do not use any items which may cause physical damage to the applicator. Non-

metallic items, such as a wooden tongue depressor or soft plastic implement, can be used to remove heavy debris. Wipe the

applicator dry when nished.

Loading...

Loading...