Disassembly/Assembly

Guidelines

IRB 6400

Page 4 - 2

Maintenance

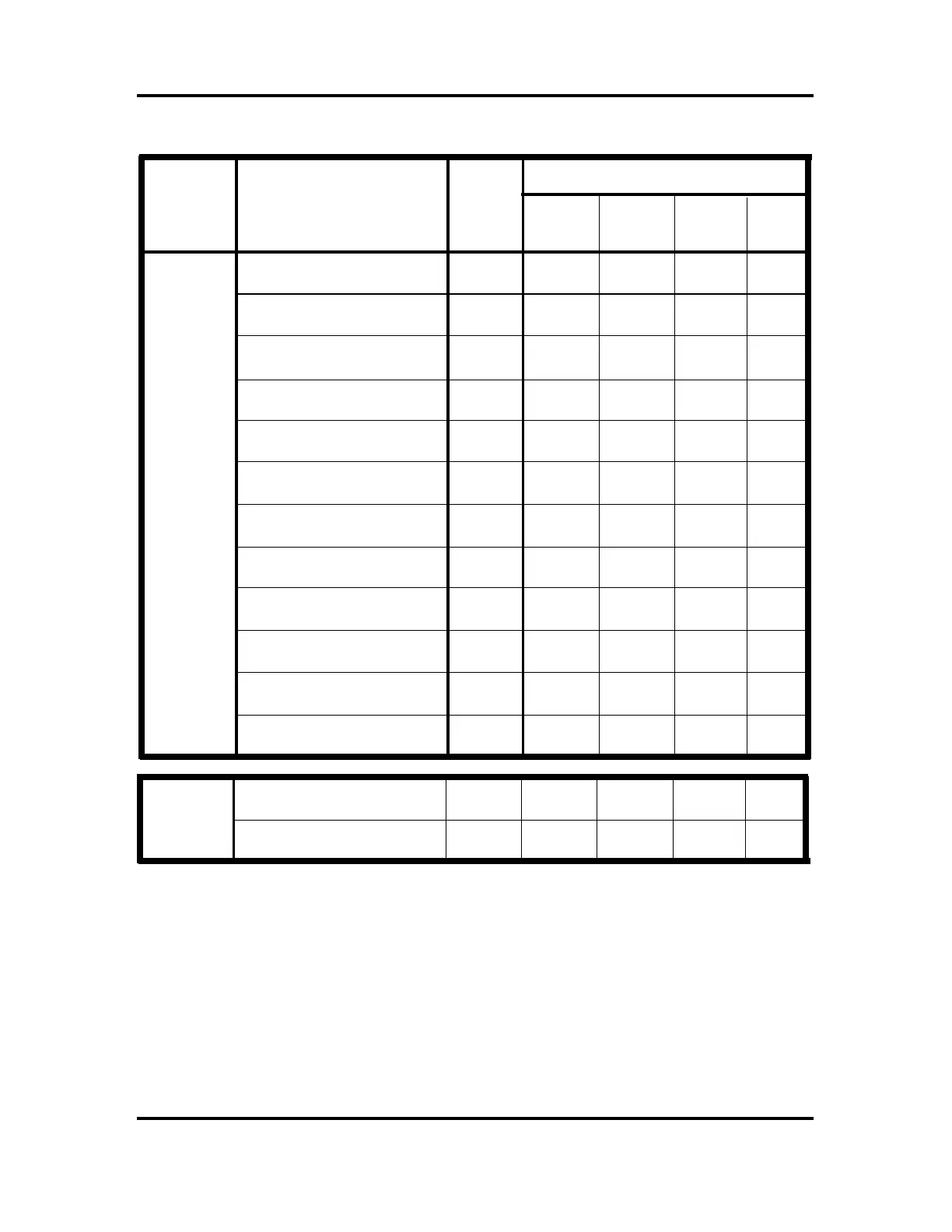

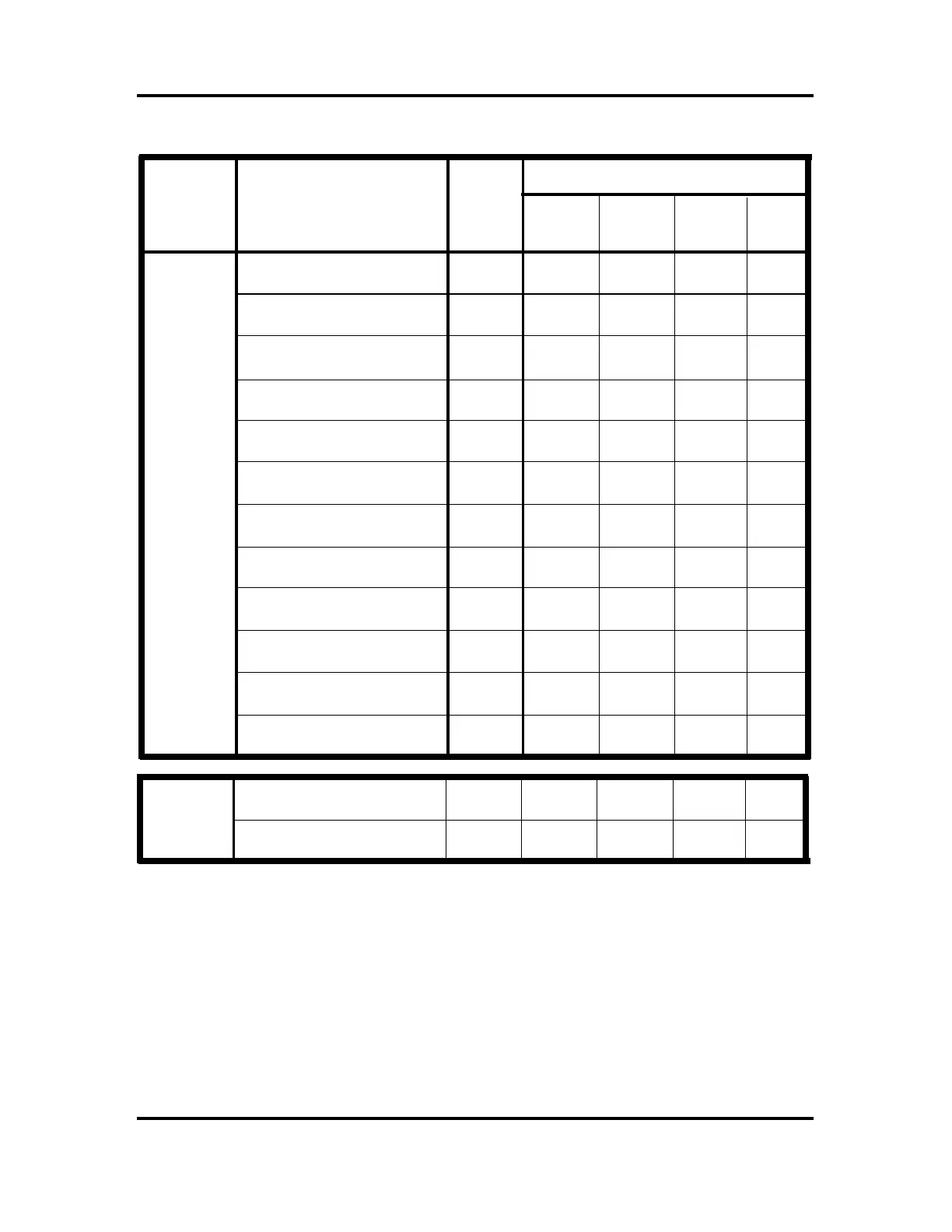

MAINTENANCE SCHEDULE

ROBOT

Large Diameter Bearing

GREASING

Cabling

Mechanical Stop Axis 1

Gearbox Axis 1

GREASE CHANGING

Gearbox Axes 2-3

GREASE CHANGING

Gearbox Axis 6

GREASE CHANGING

Oil Level in Gear 4 & 5

Gearbox 4

OIL CHANGING

Gearbox 5

OIL CHANGING

Measuring System Battery

CHECK/EXCHANGE

Cooling Motor Axis 1

FILTER CHANGING

Cooling Device

FILTER CHANGING

Memory Backup

BATTERY CHANGING

CONTROL

SYSTEM

MAINTENANCE INTERVALS

5 YEARS

4000 HRS

OR

2 YEARS

PAGE

NO.

CHECK

ONCE

A

YEAR

6000 HRS

OR

3 YEARS

X

X

X

X

X

X

X

X

Gearbox 1,2,3,6

GREASE CHANGING

3 yrs

X

XX

3 yrs

1

2

3

4

5

6

5

X

XX

XX

PRESCRIBED

MAINTENANCE

1 - Recommended interval for large movements on axis 1 (over ±45°). Typical for materals handling.

2 - Inspect all visible cabling. Change if damaged.

3 - Check the mechanical stop devices for deformation and damage. If the stop pin or the adjustable stop

arm is bent, it must be replaced.

4 - For press-tending (refers to grease changing and opera;ting life for gearboxes 1 & 6) and heavy duty

operation, axis 1 (option 5x is installed).

5 - For robot with option 51 or 5x installed. Recommended interval for filter change is every 3 months.

6 - Interval strongly dependent on the enviroment around the control system.

Loading...

Loading...