Disassembly/Assembly

Guidelines

IRB 6400

Page 4 - 6

Maintenance

Lubricating Axes 2 & 3 Gear Units (S35 )

The lubricating procedures are the lame for axis 2 and axis 3. Axis 2 is on the

robot right side. Axis 3 is on the robot left side.

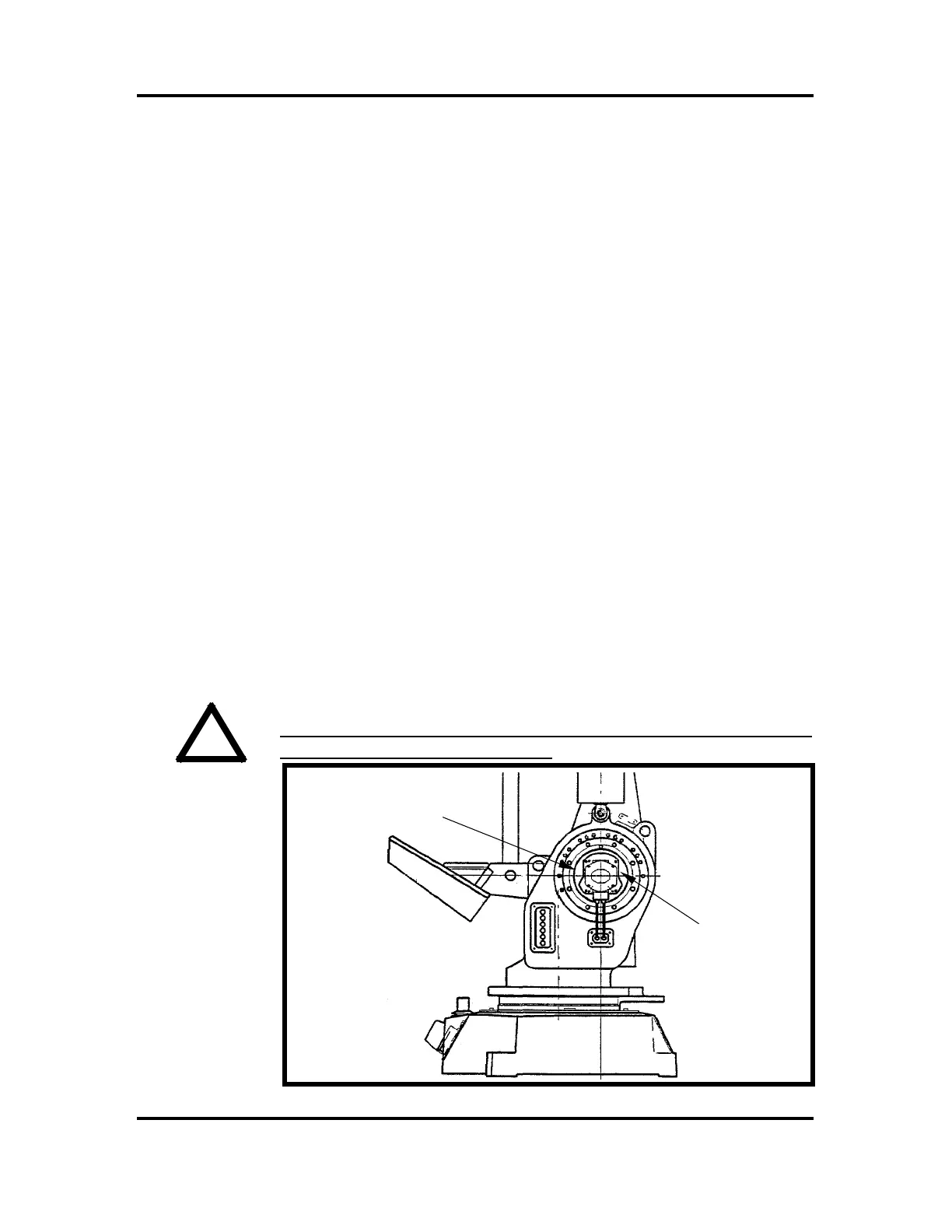

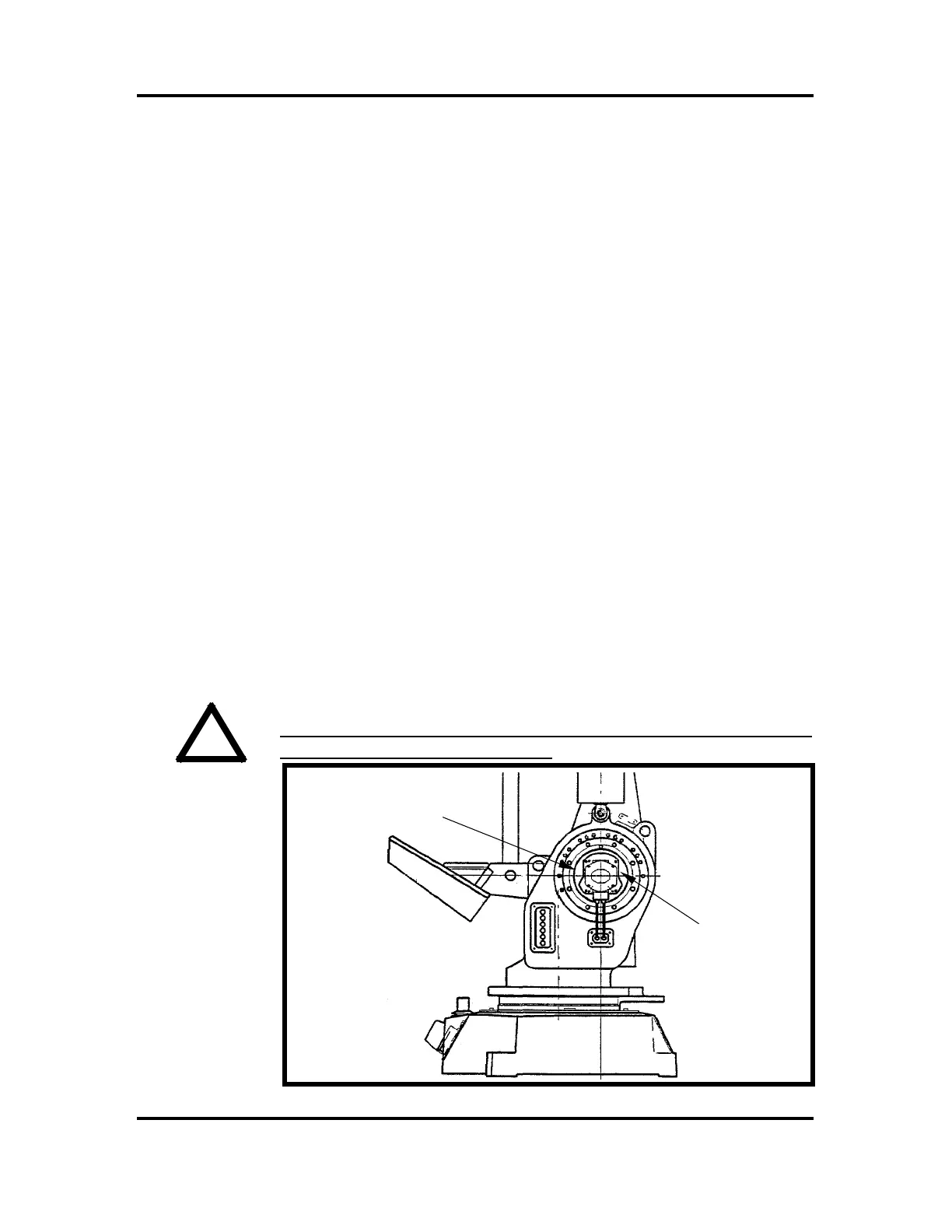

• Remove the filler (1) and drain (2) plugs. See figure below.

• Grease through the filling hole (1).

• The axes 2 and 3 shall be moved slowly backwards and forwards several

times while greasing.

• Continue greasing until new grease exudes from the drain hole (2). See

Volume below.

• Move the axes backwards and forwards a couple of times before the plugs

are replaced, so that excess grease is pressed out. This is to prevent over-

pressure in the gearbox, with risks for leakage.

Volume:

1.3 litres (0.36 US gallon).

About 2.0 litres (0.82 US gallon) should be used when changing the

grease.

Type of grease:

ABB 3HAA 1001-294

Optimol Longtime PD 0

Tools:

See Tools List, page 4-25.

CAUTION: IT IS IMPORTANT THAT THE DRAIN PLUG IS RE-

MOVED DURING LURICATION.

C

1

2

Loading...

Loading...