Disassembly/Assembly

Guidelines

IRB 6400

Page 4 - 17

Maintenance

ADJUSTMENTS

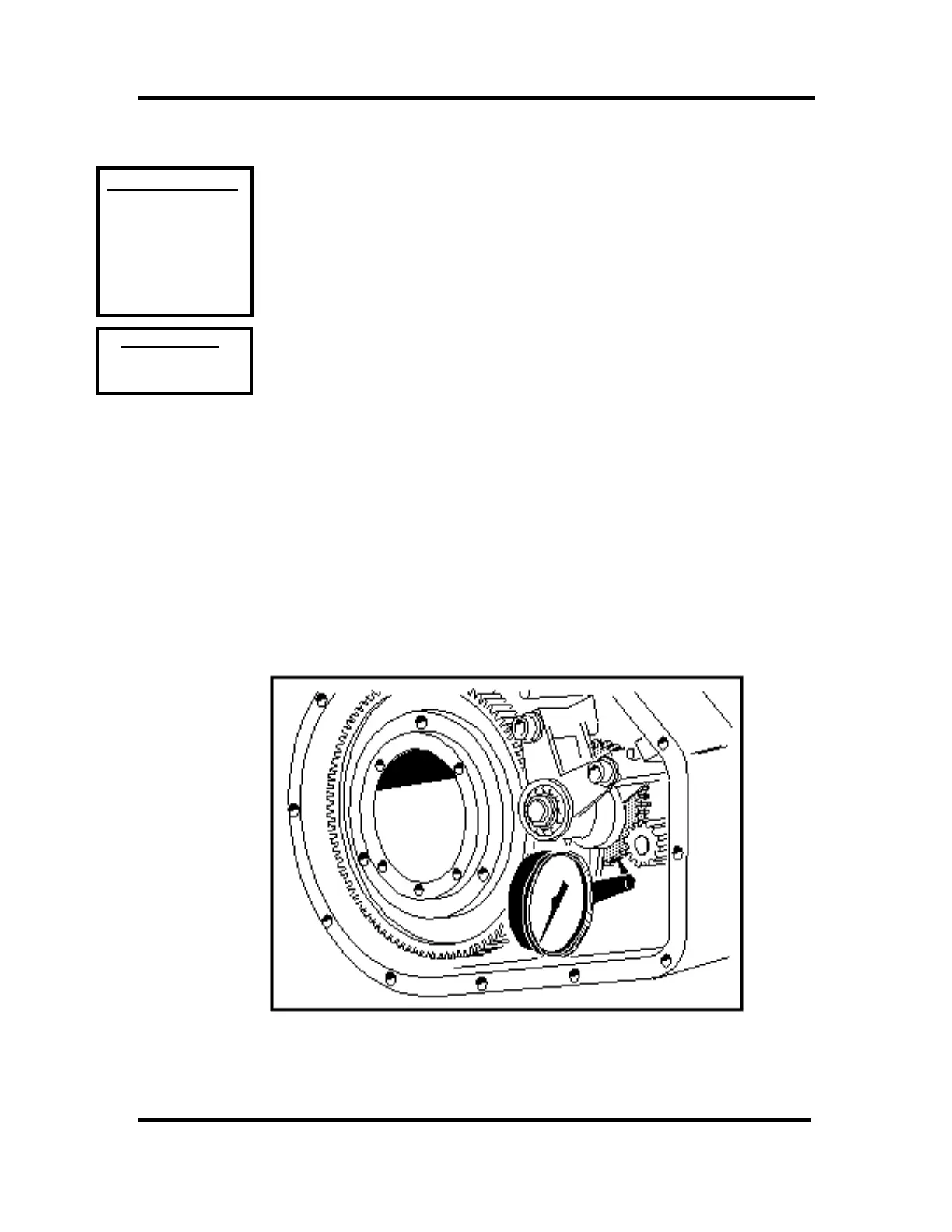

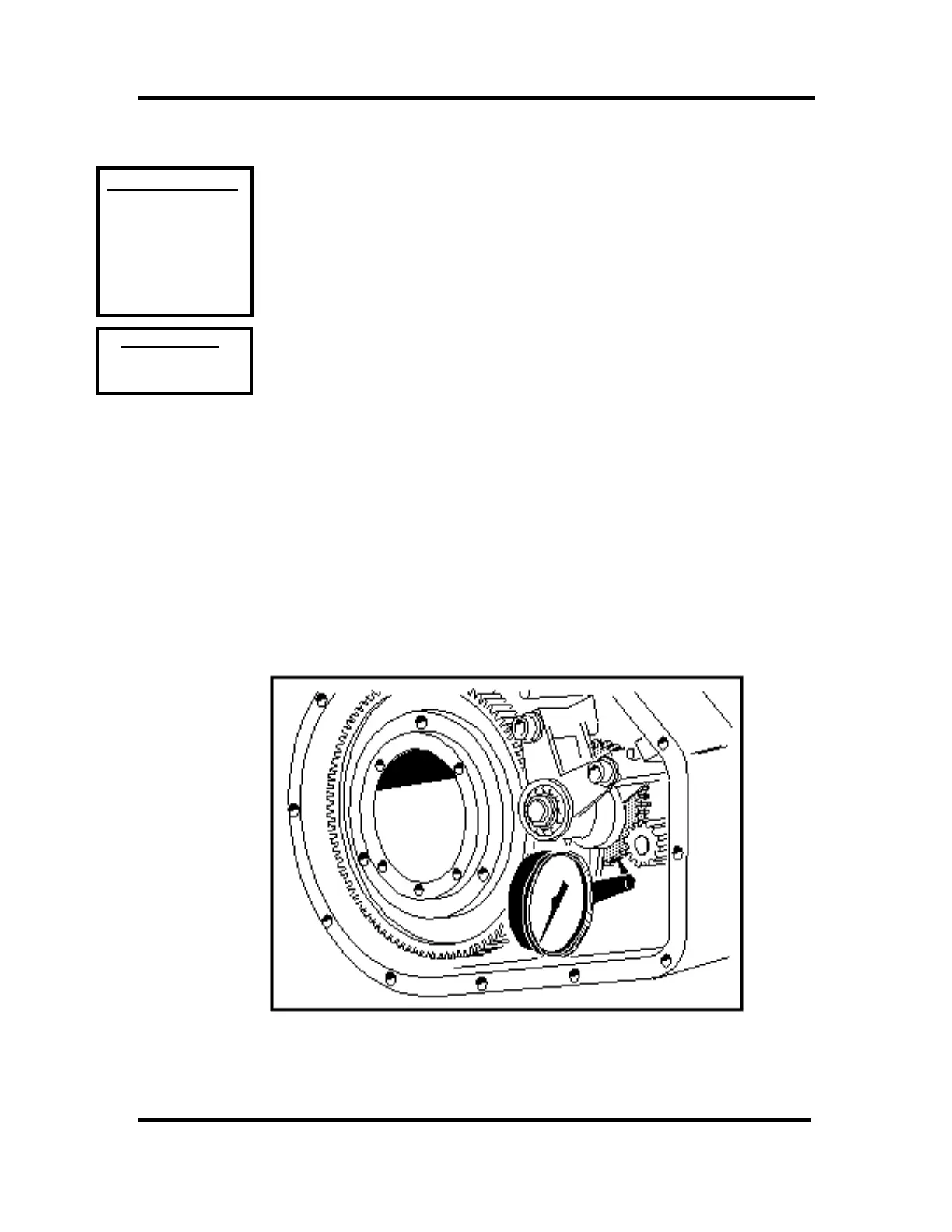

Adjusting Axis 4 Gear Play

The following conditions are to exist before play is adjusted:

1. Oil for axis 4 (U83) gearbox is removed.

2. Axis 4 (U83) motor is removed.

3. Axis 4 (U54) gearbox cover is removed.

4. Intermediate gear steel wedges (U78) are placed at even depths with

spring washers (U77) (concave sides facing) and hex nuts just hand

tightened.

5. Intermediate gear hub scres (U67) are just hand tightened.

6. Final gear (U41) and axis 4 tube shaft are mechanically locked from

rotating.

Adjusting Play Between Intermediate Gear (U74)

and Final Gear (U41):

1. Attach magnetic base of dial indicator to machined surface where the axis

4 motor mount to the upper casting.

2. Set dial indicator to read on large diameter intermediate gear (U74) tooth

slot.

3. Shift hub (U72) around until play is between 0.0004-0.001 in.

4. Tighten three screws (U67) to a torque of 52ft-lbs.

5. Tighten hex nuts (U76) to a torque of 9 ft-lbs..

6. Recheck play and re-adjust if necessary.

7. Check a minimum of 4 places around the intermediate gear for high or low

spots.

REFERENCE DRAWINGS

Exploded View:

3HAA 0001-AP (page 13-15)

Assemblies:

“U” (pg 12-4)

3HAA 0001-CS (page 13-14)

3HAA 0001-CS (page 13-17)

REQUIRED TOOLS

Torque Wrench (9-52 ft-lb)

Loctite 242

Dial Indicator

Loading...

Loading...