ADT-HC4500 Flame/Plasma Cutting Machine CNC System

- 98 -

3.1. G92 reference point setting

When setting program running, the coordinates of processing start (reference point) must be put at the start of

the program.

Format: G92 X0 Y0

If G92 isn’t followed by X, Y, the current coordinates of X, Y will be the reference point. Generally, if the

origin of machine tool is used for positioning, G92 won’t be followed by X, Y.

3.2. G21/G20 metric/imperial system setting

Set the length unit (default: metric) of program processing

G20: imperial (unit: inch)

G21: metric (unit: mm)

Format: G21

This instruction sets the length unit (mm) of processing. It is usually written in the second line of the program

(unless temporary change is required), i.e. next line of G92. The instruction isn’t followed by any content, and

will persist until next G20 or G21.

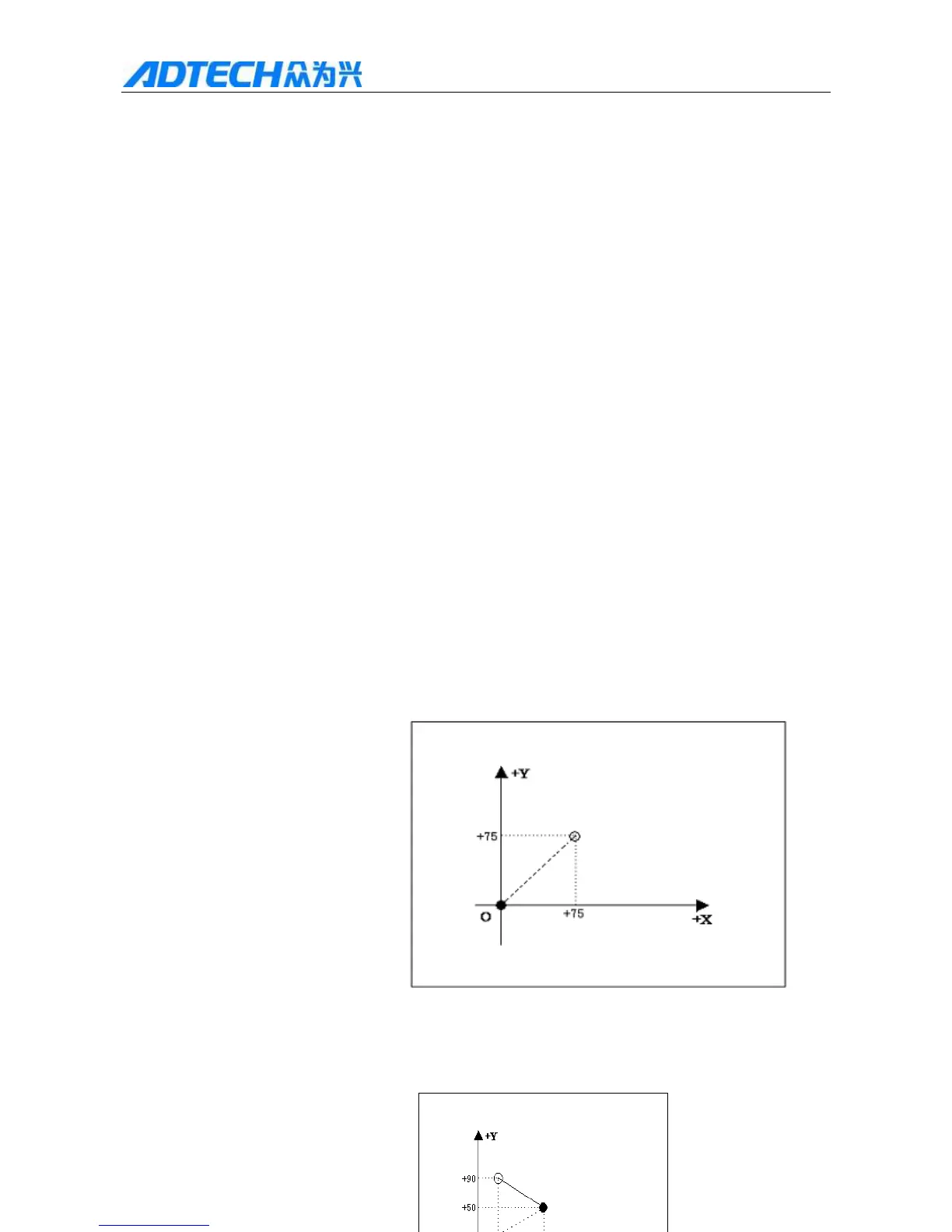

3.3. G00 space shift

This instruction can return the torch to specified position quickly, and the system moves from start to end in linear.

The processing is at run idle speed, i.e. maximum manual speed, and isn’t controlled by percentage.

Format: G00 Xn Yn

For example: G92 X0 Y0

G00 X75 Y75

M02

Current position of torch

Expected position of torch

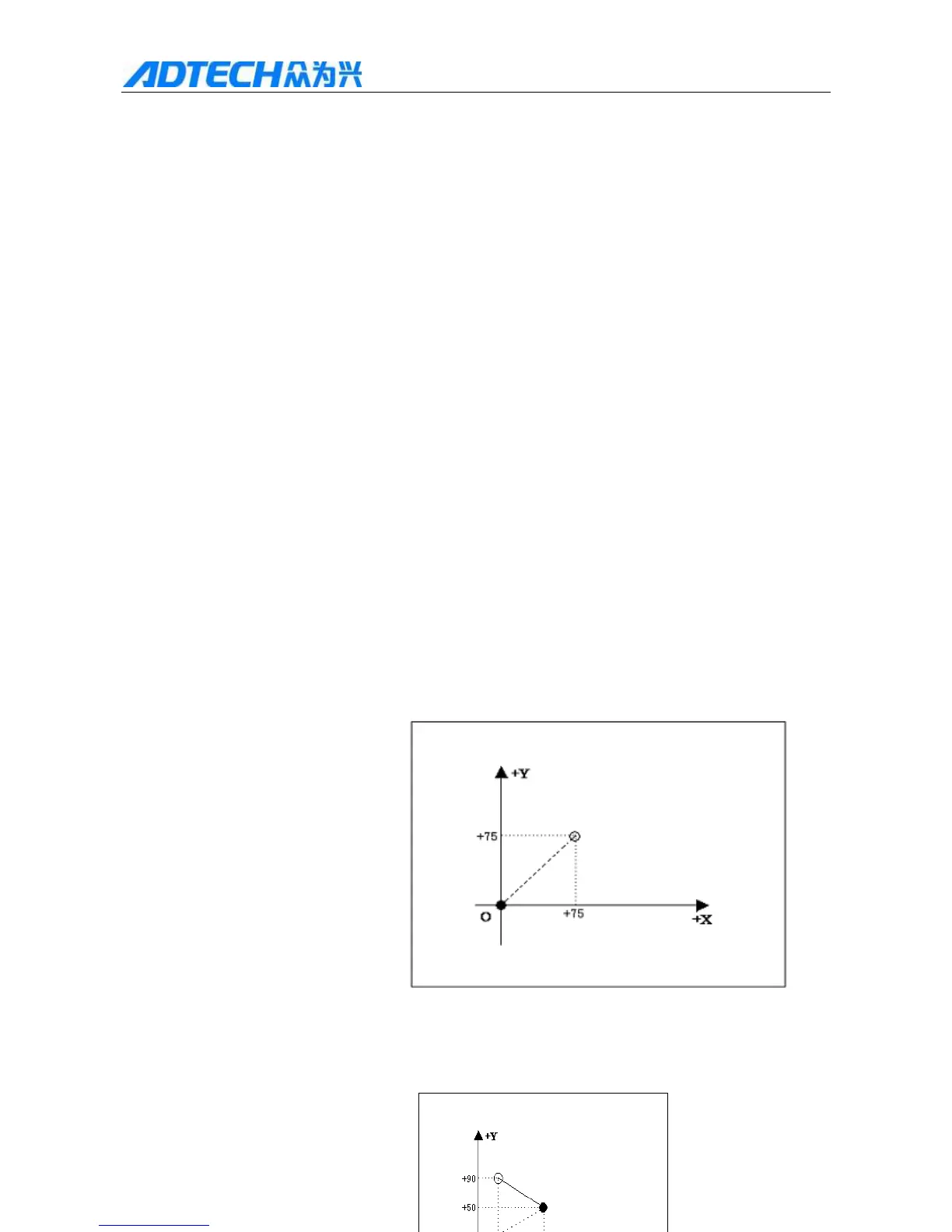

3.4. G01 straight line cutting

This instruction can feed the torch to specified position in linear and single axis or two axes linear interpolation is

allowed as cutting instruction.

Format: G01 Xn Yn

For example:

Loading...

Loading...