Maintenance

Testing the Control Interlock System 7.9

77

[en-US] | 08/2022 | 5100064108 | SM100 | Operator’s Manual

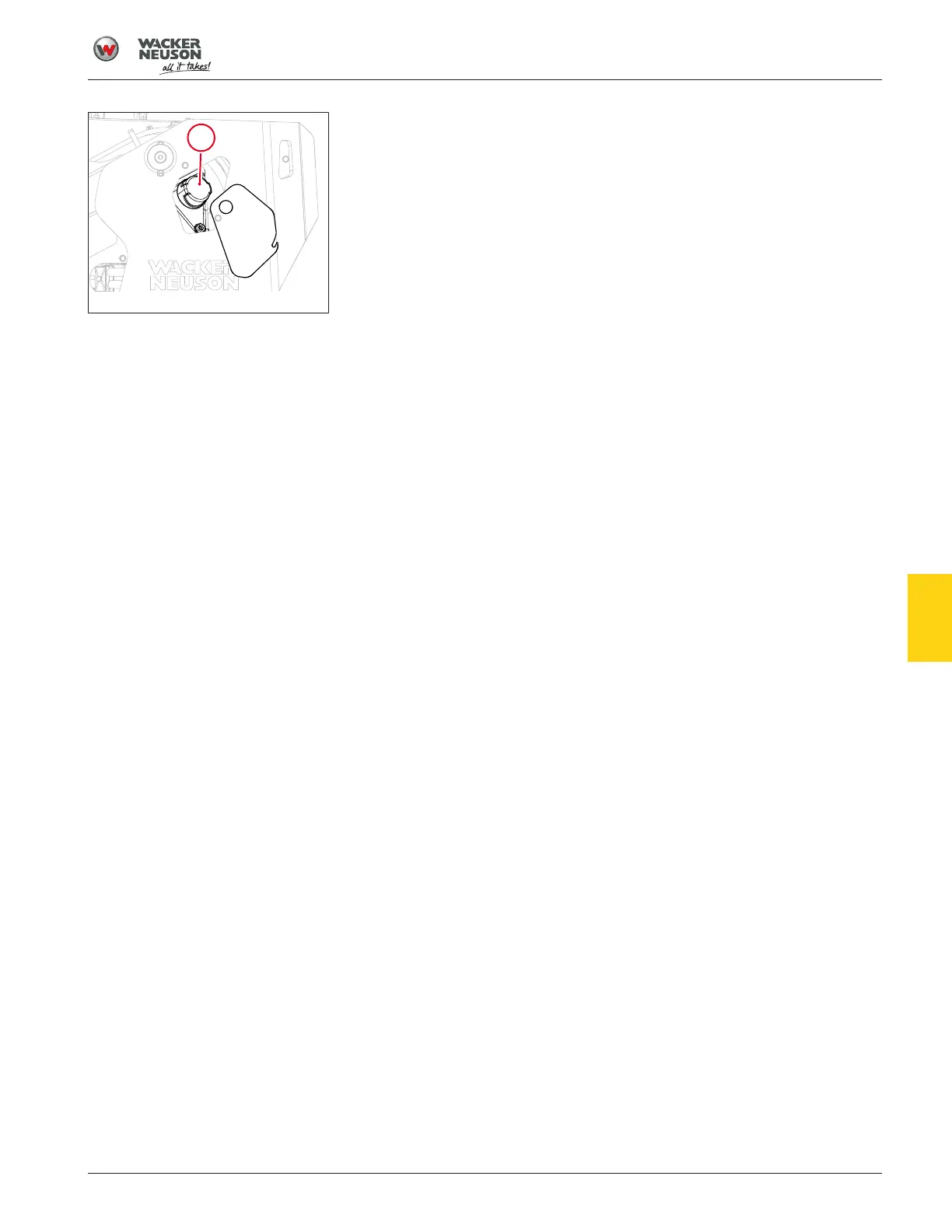

Fig.59: Hydraulic oil filler cap

4. Clean the area around the hydraulic tank filler cap(4).

5. Remove the hydraulic tank filler cap and fill the hydraulic oil to a level

half full in the sight glass.

6. Rotate the access plate into place and tighten the bolts.

7.9 Testing the Control Interlock System

When

Every 10 hours or daily

Procedure

To enable the ground drive, loader lift and tilt, and auxiliary hydraulics, the

operator must complete all of the following actions:

1. Stand on the operator platform and engage the operator presence

pedal.

2. Start the engine.

3. Disengage the parking brake.

To test the control interlock system, perform the following functions individu-

ally with the engine running and the controls enabled. A successful test

means that the machine will not move after each of the following tests are

performed:

• Disengage the operator presence pedal, wait 5seconds, and move the

ground drive controls, lift arm controls, and auxiliary hydraulic controls.

• With operator presence pedal engaged, disengage the parking brake

and move the ground drive control only.

Note: After all controls are enabled, pressing the brake switch will only en-

gage the parking brake and limit the ground drive controls to hold the ma-

chine stationary. This allows the machine to operate the lift arm controls or

auxiliary controls while preventing the machine from moving—for example,

drilling a post hole while working on a slope.

Testing the lift arm controls interlock

1. Stand on the operator platform with the operator presence pedal en-

gaged and start the engine.

2. Raise the lift arm slightly off the ground.

3. Shut down the machine and wait for the engine to stop completely.

4. Make sure the area around the machine is clear.

5. Move the right joystick forward to lower the lift arm.

ð The lift arm should not lower.

7

Loading...

Loading...