Maintenance

General Daily Checks 7.3

71

[en-US] | 08/2022 | 5100064108 | SM100 | Operator’s Manual

7.3 General Daily Checks

• Perform an overall visual check of the machine:

– Clean dirt and debris from the operator platform.

– Check for loose and broken parts, instrument operation, and oil

leaks.

• Visually inspect the engine compartment, including the engine itself. If

you find any problems during the visual check, take the necessary cor-

rective action before operating the engine.

• Visually inspect all hydraulic system components. Check the hydraulic

fluid level and check for leaks. For further information, see Checking the

Hydraulic Oil Level on page 76 and see Checking for Leaks on page

78.

• With the key switch in Position 1, check the following:

– Indicator lights—If any indicator fails to illuminate when the key

switch is in Position 1, contact an authorized Wacker Neuson dealer

or service center for assistance before operating the engine.

– All other lights, such as work lights

• Check the parking brake for proper function.

• Check the lift arm piston rods for any signs of damage or leakage.

• Check the hydraulic couplings for dirt or debris that may prevent the lines

from seating properly.

• Check the attachment coupler for damage. Make sure the pins engage

and the lock levers move.

• Check all line fixtures, such as clamps, cable ties, brackets, or other

components that secure lines and hoses.

• Check the tie-down points for any damage such as cracks in the weld-

ment.

• Check for damaged safety labels. Replace any damaged safety labels.

7.4 Operating the Hood

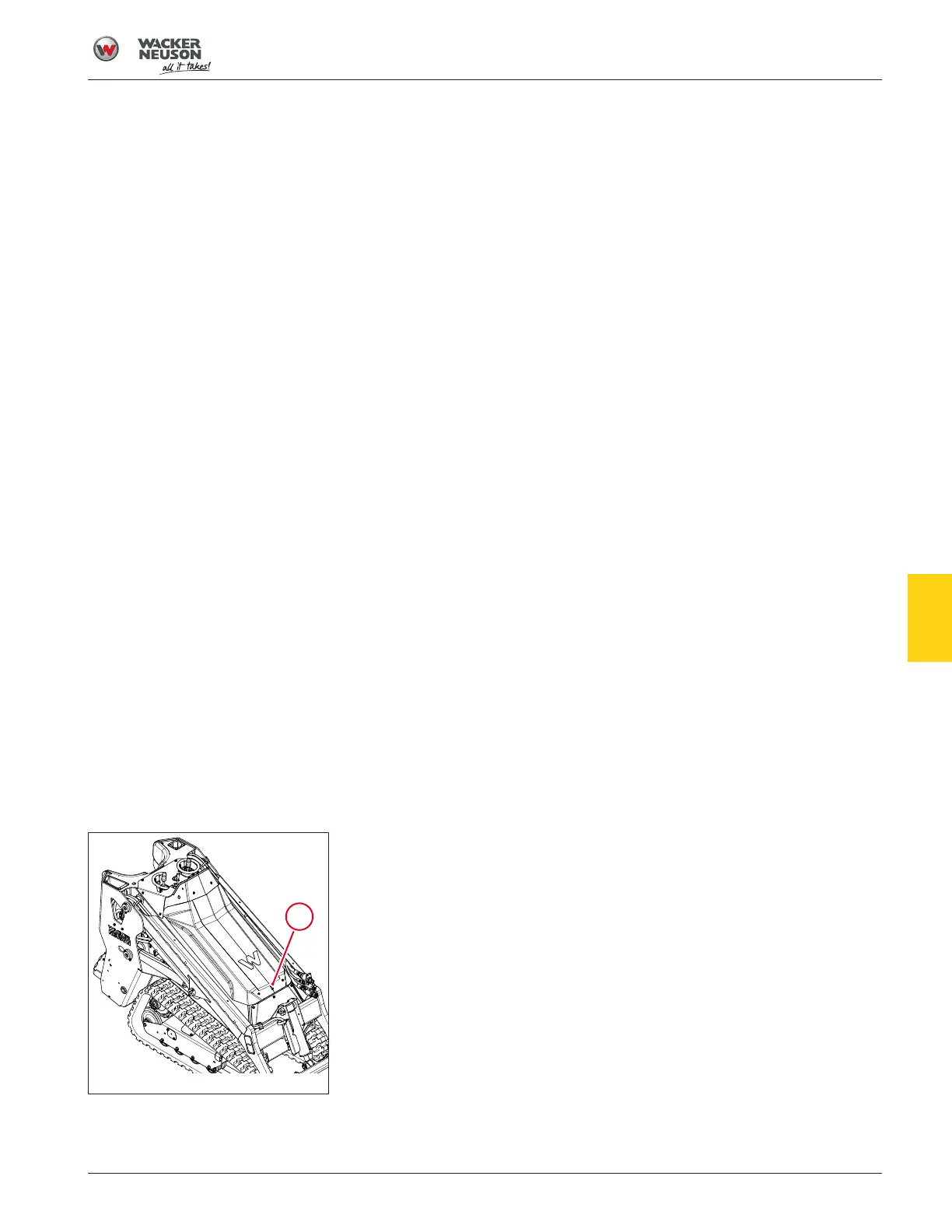

Fig.53: Hood lock eye

Opening and Closing

1. Remove the lock (if applicable).

2. Pull up to open. (The hood is “locked” in place using rubber door

latches.) The hood remains open by itself with a gas strut at the left

hood hinge.

3. Lower the hood slowly to make sure the lock eye(1) goes through the

hole in the hood and the door latches engage properly.

4. Push down firmly to engage the door latches.

5. Install the lock (if applicable).

7

Loading...

Loading...