Maintenance

7.17 Checking and Adjusting the Drive Belts

88

Operator’s Manual | SM100 | 5100064108 | 08/2022 | [en-US]

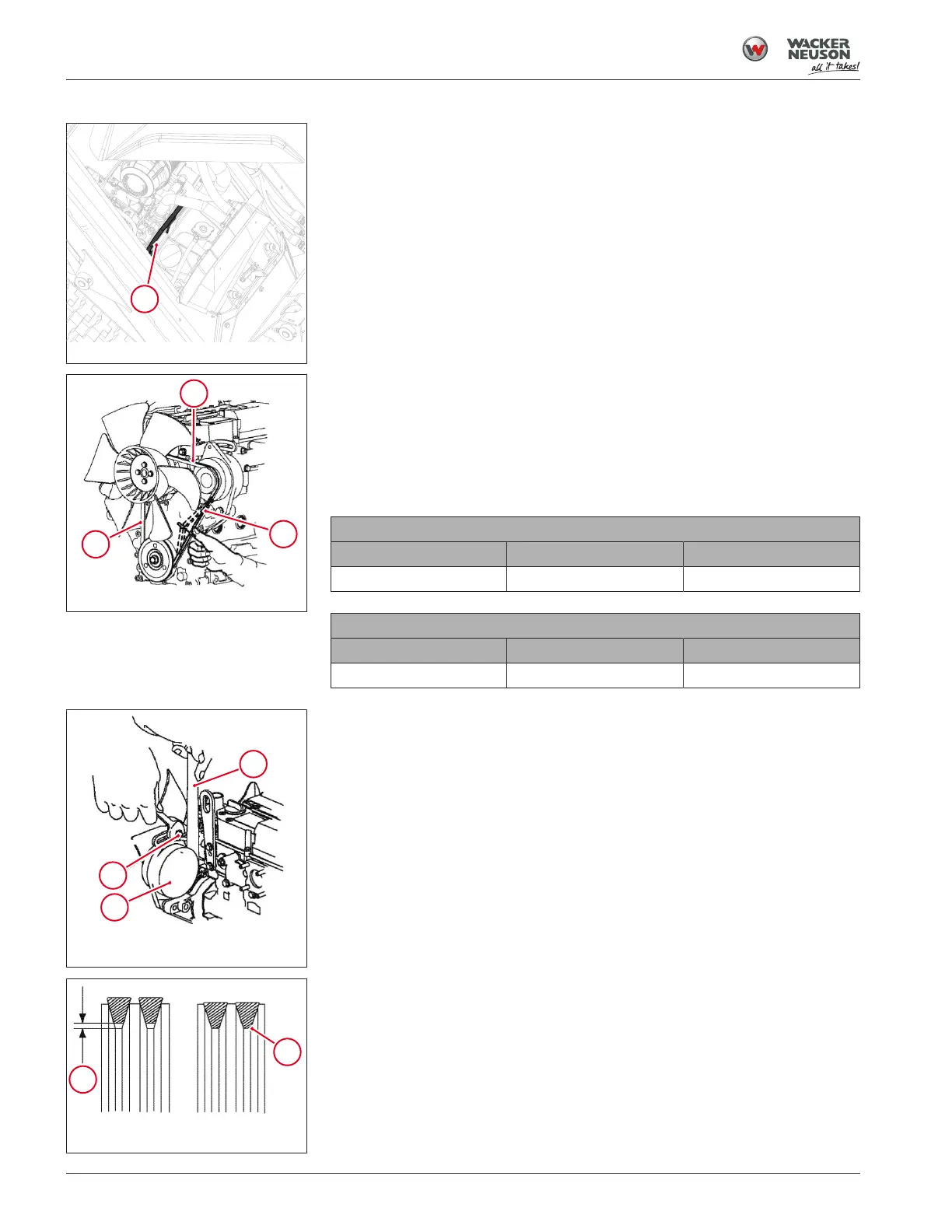

Fig.73: V-belt location

Checking the cooling fan V-belt

1. Open the hood.

2. Check the belt (1) tension using a belt tension gauge or by pressing the

belt down with your thumb. Check the tension in whichever position (A,

B, or C) is most accessible.

Fig.74: Belt tension check positions

3. Check the tension values in the applicable table below.

Note: A “used” V-belt is a belt that has been used on a running engine

for five minutes or more.

4. Check the belt condition.

5. Adjust the tension or replace the belt as needed.

New V-belt Tension

A B C

8–12 mm (5/16–7/16 in.) 5–8 mm (3/16–5/16 in.) 7–11 mm (1/4–7/16 in.)

Used V-belt Tension

A B C

10–14 mm (3/8–1/2 in.) 7–10 mm (1/4–3/8 in.) 9–13 mm (5/16–1/2 in.)

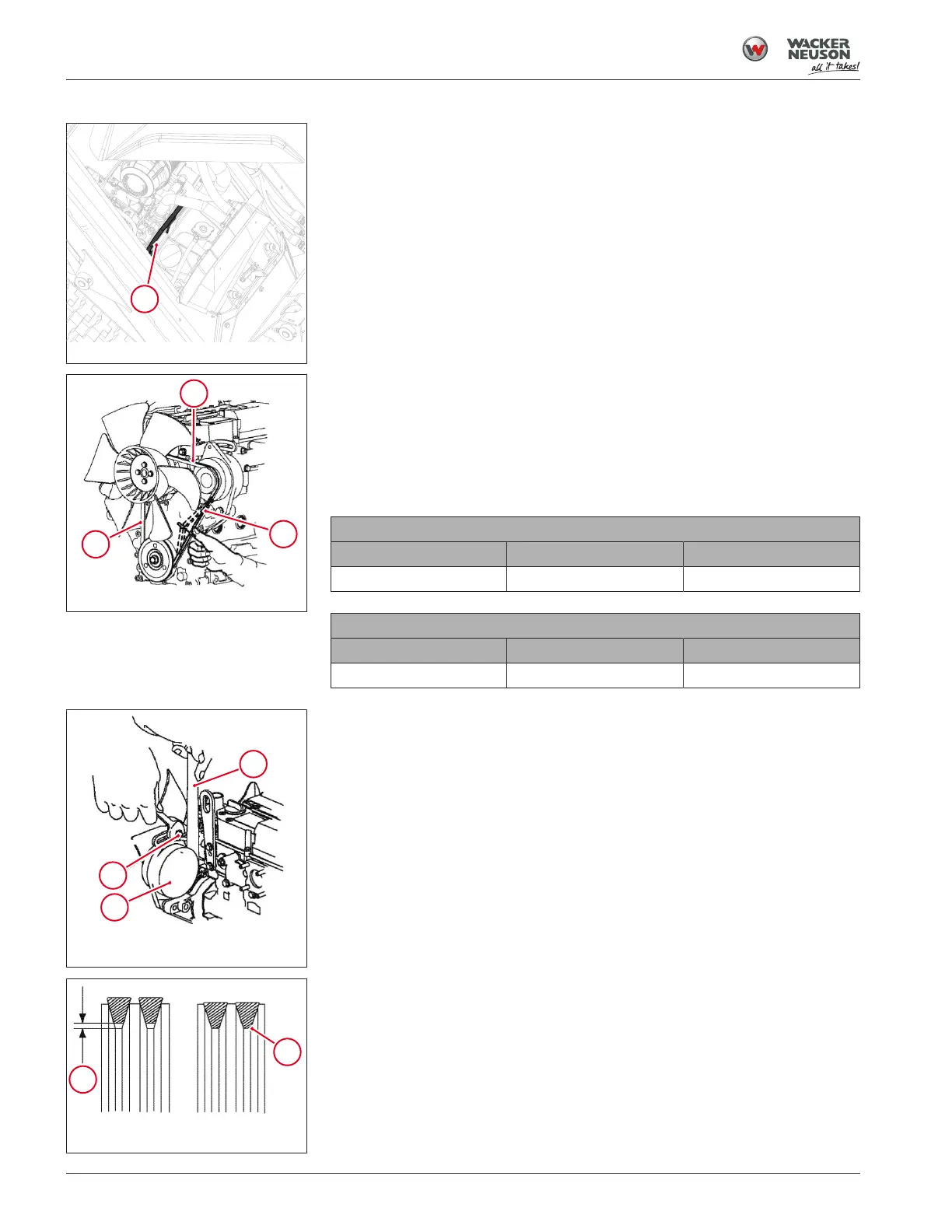

Fig.75: Cooling fan V-belt adjust-

ment

Adjusting the cooling fan V-belt

1. Loosen the alternator adjusting bolt (2) and any other related fasteners.

2. Adjust the belt tension by pivoting the alternator (3) in or out using a

pry bar (4).

3. Tighten the alternator adjusting bolt and related fasteners and check

the belt tension.

Fig.76: Clearance between V-belt

and pulley groove

4. Repeat these steps until you achieve the desired belt tension.

ð There must be clearance (5) between the V-belt and the bottom of

the pulley groove. If there is no clearance (6) between the V-belt and

the bottom of the pulley groove, replace the V-belt.

5. After adjusting the tension, run the engine for at least 5 minutes. Check

the tension again using the specifications for a used V-belt.

Loading...

Loading...