Chapter 2 Dispensing to SpectroCHIP Arrays 39

USG-CUS-059 Rev05MassARRAY® Nanodispenser RS1000 v2.1 User Guide

For Research Use Only. Not for use in diagnostic procedures.

2.6 Microtiter plate checks

Checking the resin and

liquid levels

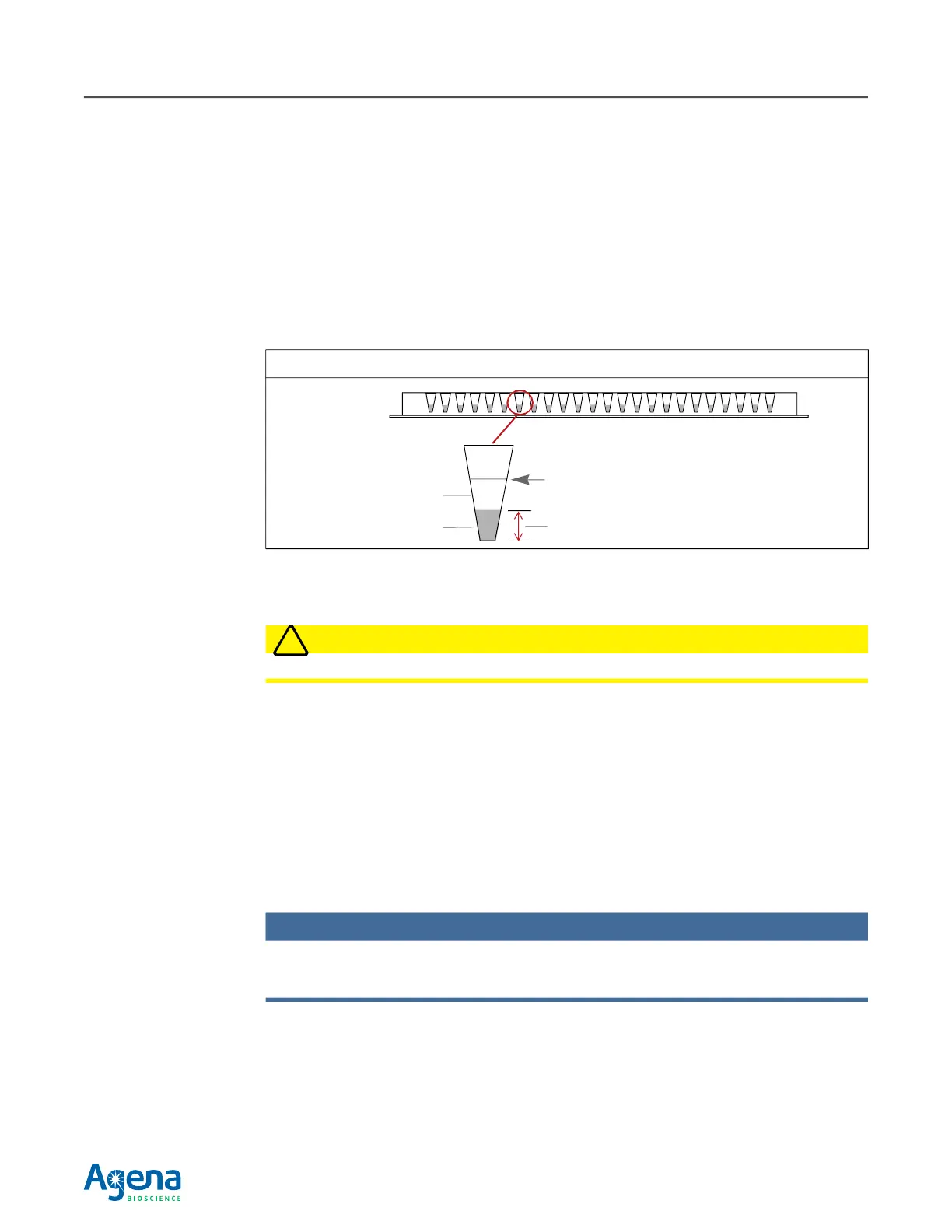

A layer of Clean Resin (yellow or brownish-yellow color) underlies a liquid analyte layer in

a microtiter plate well. The levels of the resin and liquid must be checked to ensure they

are adequate for nanodispensing. This section uses a 384-well plate as an example, but

the process is the same for a 96-well plate. (See Figure 2.32 for a 96-well example.)

In a 384-well microtiter plate, the resin level should come up no higher than 4.5-5.0 mm

from the bottom of the wells (Figure 2.27). In each well, the liquid (analyte) above the

resin should be at least 2.5 mm higher than the top of the resin layer.

To adjust the resin or analyte level:

CAUTION

!

Use a new pipette tip for each well to avoid cross-contamination of samples.

1. If a well has too much resin:

a. Pipette some out until the distance to the top of the resin layer (from the bottom

of the well) is no higher than the maximum value (see (Figure 2.27). Pipette

carefully, removing only what is necessary.

b. Centrifuge the microtiter plate for 3 minutes at 1600 x g.

2. If the liquid level (analyte) in the wells is less than 2.5 mm above the resin (Figure

2.27):

a. Bring up the liquid level by adding HPLC-grade water with a pipette.

b. Check to make sure that the liquid level is uniform across all wells.

NOTENOTE

There is a maximum allowable level of resin in the wells, but there is no minimum. If a well has a

lower resin than others, the liquid level above the resin may come up to a lower point. (See the

following example.)

Figure 2.27 Checking the Resin Level in the Microtiter Plate Wells

Resin

Cross-section of

a microtiter plate

4.5-5.0 mm maximum (6 mg resin plate)

Analyte

The top of the liquid level (analyte) must be at

least 2.5 mm higher than the top of the resin layer

Loading...

Loading...