28 Rockwell Automation Publication 1766-UM001I-EN-P - June 2015

Chapter 3 Wire Your Controller

• Separate wiring by signal type. Bundle wiring with similar electrical

characteristics together.

• Separate input wiring from output wiring.

• Label wiring to all devices in the system. Use tape, shrink-tubing, or other

dependable means for labeling purposes. In addition to labeling, use

colored insulation to identify wiring based on signal characteristics. For

example, you may use blue for DC wiring and red for AC wiring.

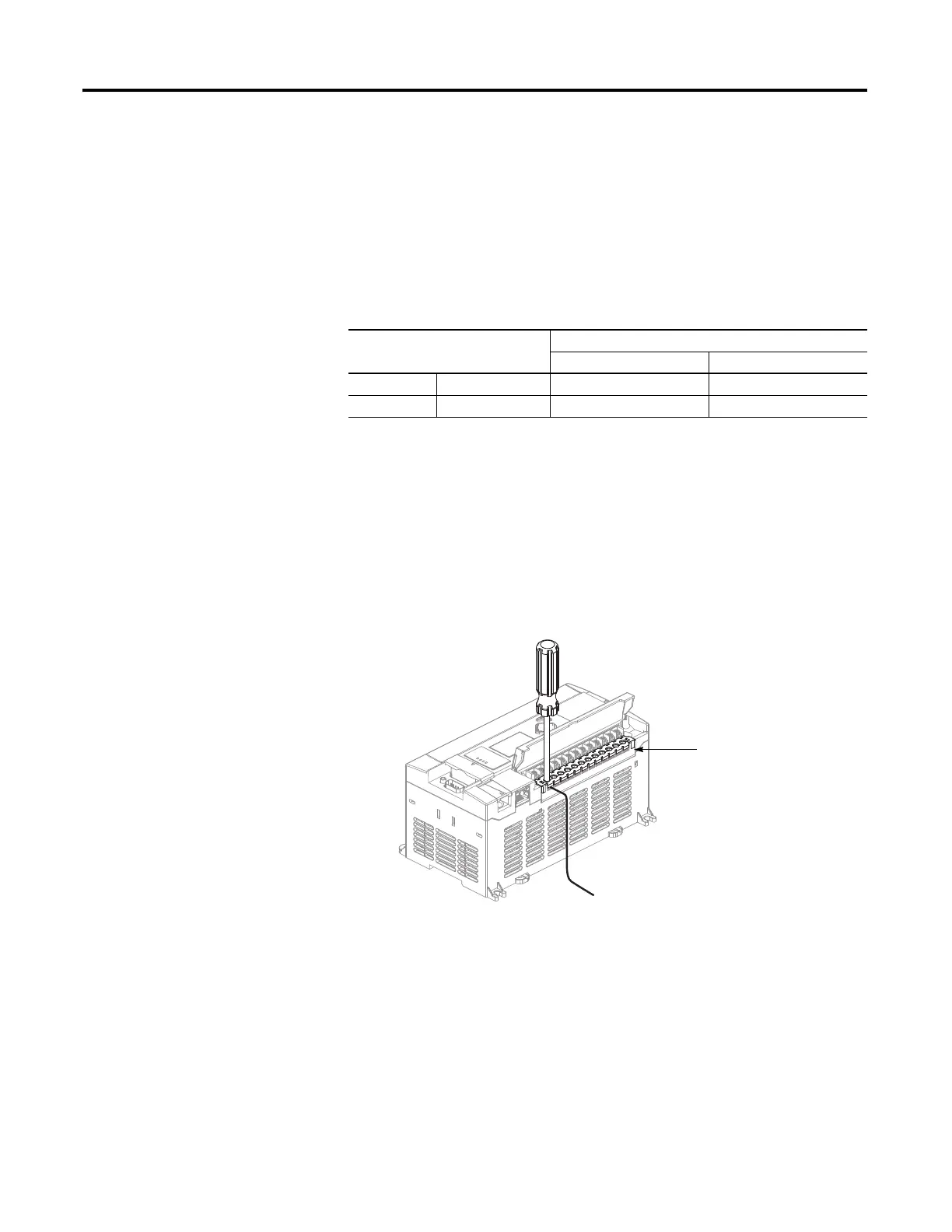

Wire without Spade Lugs

When wiring without spade lugs, it is recommended to keep the finger-safe covers

in place. Loosen the terminal screw and route the wires through the opening in

the finger-safe cover. Tighten the terminal screw making sure the pressure plate

secures the wire.

Wire with Spade Lugs

The diameter of the terminal screw head is 5.5 mm (0.220 in.). The input and

output terminals of the MicroLogix 1400 controller are designed for a 6.35 mm

(0.25 in.) wide spade (standard for #6 screw for up to 14 AWG) or a 4 mm

(metric #4) fork terminal.

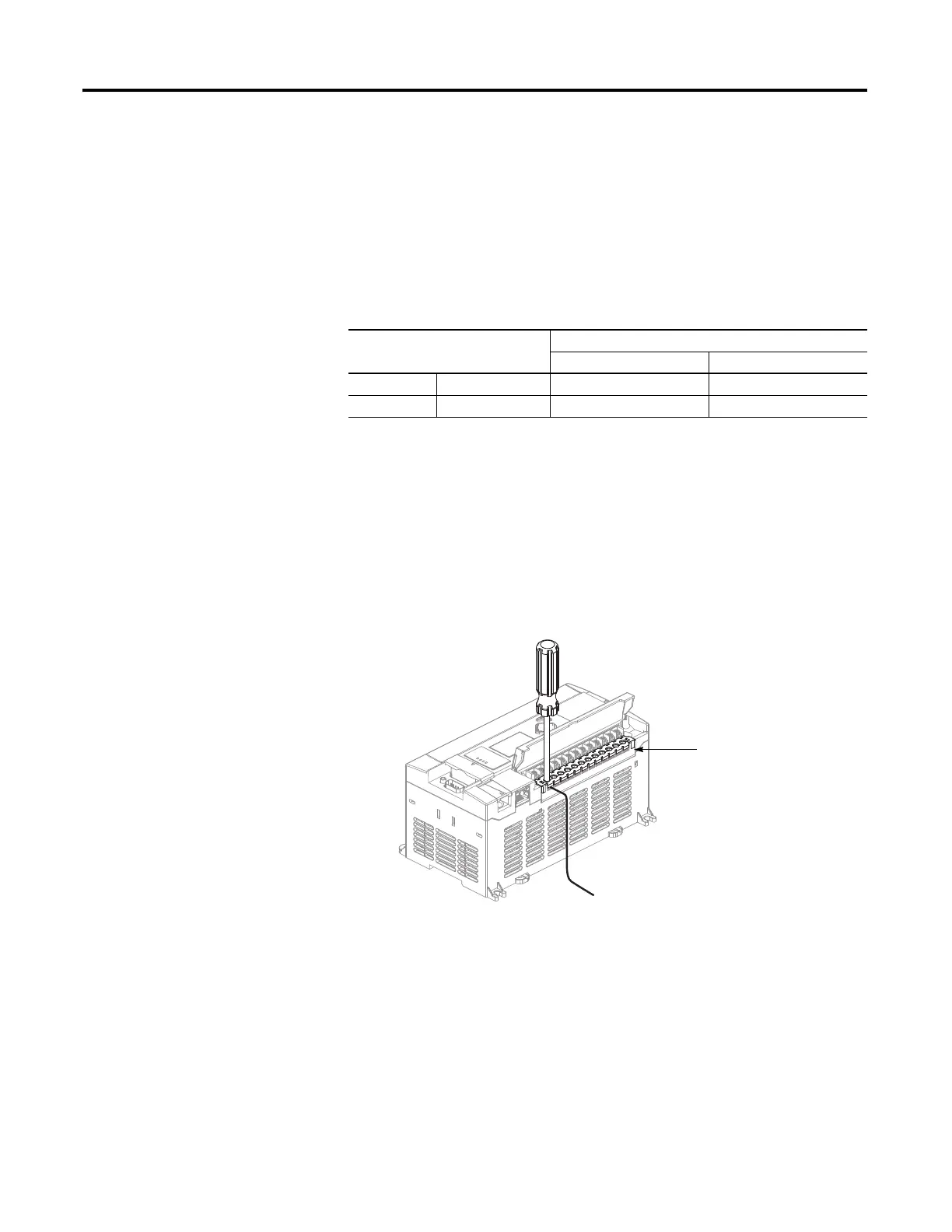

Wire Requirements

Wire Type Wire Size (2 wire maximum per terminal screw)

1 wire per terminal 2 wire per terminal

Solid Cu-90°C (194°F) #12 to #20 AWG #16 to #20 AWG

Stranded Cu-90°C (194°F) #14 to #20 AWG #18 to #20 AWG

Wiring torque = 0.56 Nm (5.0 in-lb) rated

Loading...

Loading...