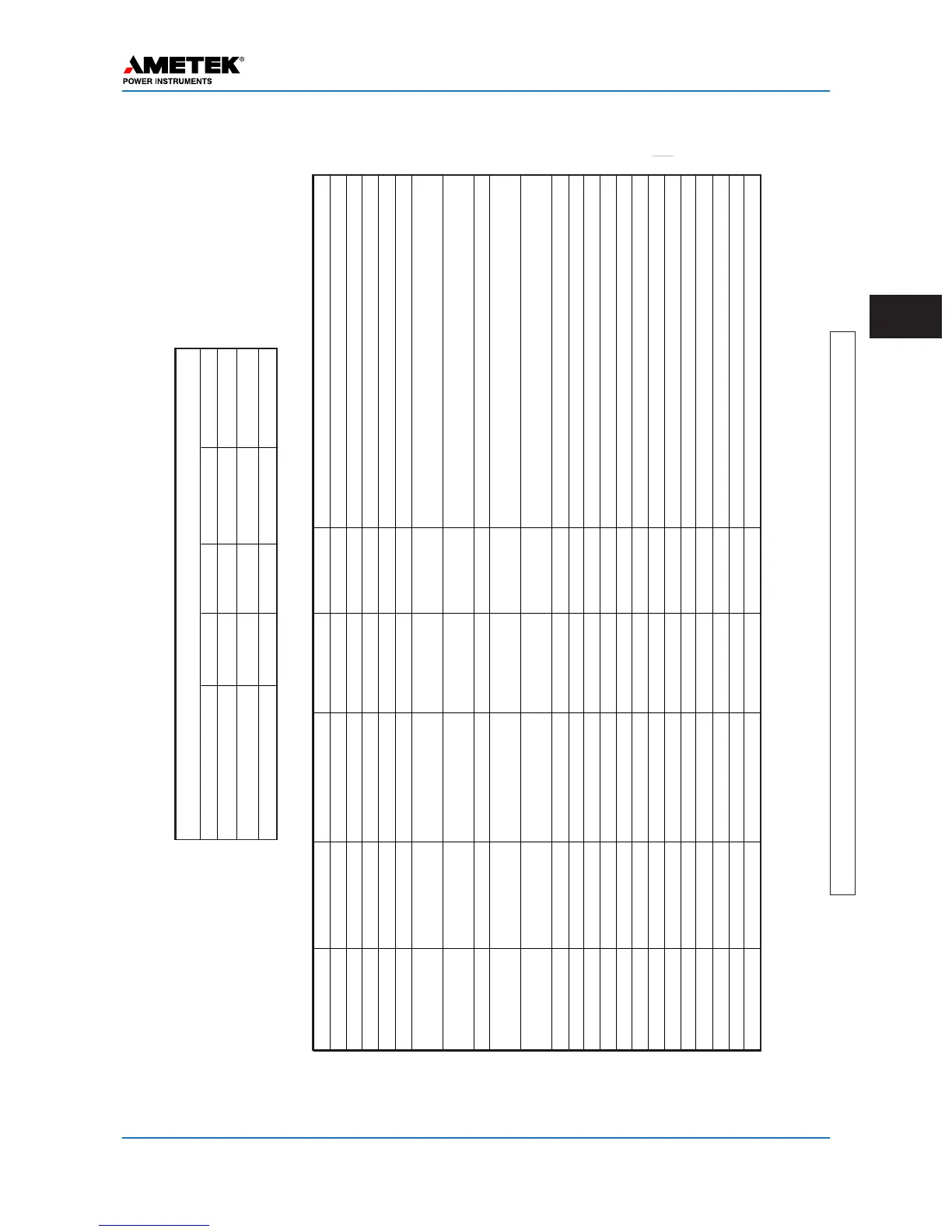

Module Function Software Selection Hardware Selection Label on board Recommendation

Backplane Coax Setting 2 wire/4 wire JMP3/JMP5 2 Wire

# of P

As

1 P

A/2P

A

JMP2/JMP6 Per factory

Coax Impedance

50 W /75 W

JMP1/JMP4

50 W

*

Power Supply Power PwrOn/ PwrOf

f

JMP3 PwrOn

Alarm Contact NO/NC JMP1/JMP2 Per Engineering

Aux Power Supply Holding current 20 mA/200 mA 8V(200 mA) or

46/20V(20 mA)

JMP1/JMP2 Per carrier relay requirement

(JMP3 is used only for 46/20V outputs when JMP1/JMP2 is in 46/20V position)

Logic Common Start/Stop

Keying Input

Enable

Input/Output

Input 1 Carrier Start Application of V

oltage

15/48/125/250 Vdc Input 1 Set to voltage setting one step below station battery

, ie

–

125 Vdc battery

, use

48 volt jumper

Input 2 Carrier S top Application of voltage 15/48/125/250 Vdc Input 2 Set to voltage setting one step below station battery

, ie

–

125 Vdc battery

, use

48 volt jumper

Input 3 Low Level Key Application of voltage 15/48/125/250 Vdc Input 3 Per Engineering

Input 4 15/48/12 5/250 Vdc Input 4 Per Engineering

Input 5 15/48/125/250 Vdc Input 5 Per Engineering

LL

Output 1

Blocking Output (NO) 0.1/1.0

A

LL01 1.0

A

LL

Output 2

0.1/1.0

A

LL02 Per Engineering

LL

Output 3

0.1/1.0

A

LL03 Per Engineering

LL

Output 4

0.1/1.0

A

LL04 Per Engineering

LL

Output 5

0.1/1.0

A

LL05 Per Engineering

LL

Output 6

0.1/1.0

A

LL06 Per Engineering

LL

Output 7

0.1/1.0

A

LL07 Per Engineering

LL

Output 8

NO/NC LL08 Per Engineering

LL

Output 9

NO/NC LL09 Per Engineering

LL

Output

10

General

Alarm

NO/NC LL10 Per Engineering

* Or per engineering

’

s recommendation

Programming /Jumper

T

able

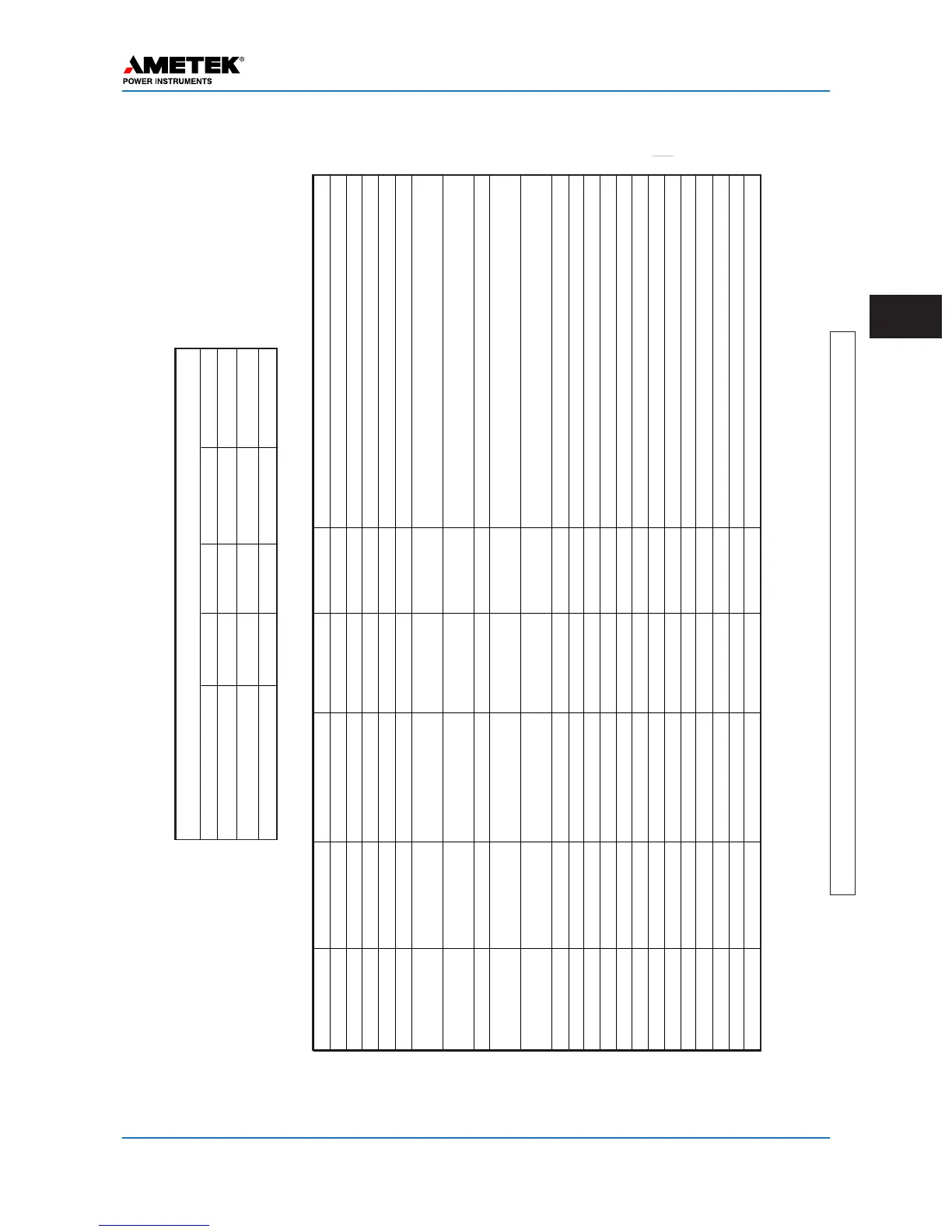

Condition Carrier Start Carrier Stop Idle (no start/stop)

Both start & stop

V

oltage across Stop Input

15V 125V 62.5V 125V

V

oltage across Start Input

1

10V

0V 62.5V 0V

Result Start Carrier Stop Carrier Stop Carrier Stop Carrier

Conditions of UPLC-II inputs for use with KA4 electromechanical relay (Stop Priority)

Loading...

Loading...