540

PROPULSION SYSTEMS

Studio ti 03312 540-04usa

148

8

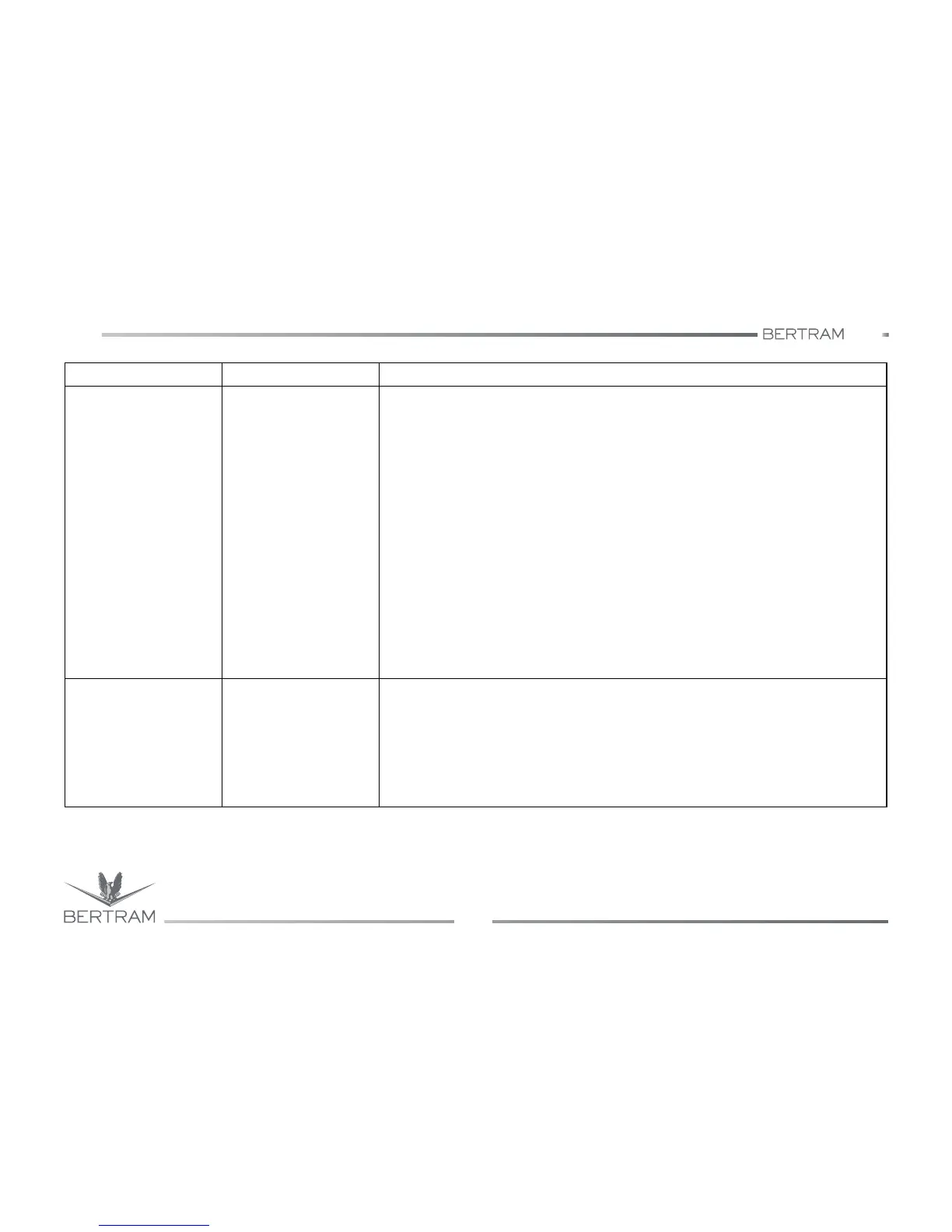

Paper air filter Replacement

Cleaning

Pressurized water

Pressurized air

Vacuum cleaning

Washing with nonsuding

detergent

Dry the paper filter

Remove the cover. Remove the element.

Cover the orifice of the air inlet with a clean rag, or seal it with some tape to avoid the

penetration of dirt and dust into the engine.

Clean the inside of the cover and of the air filter housing with a clean and dry rag. Clean the

element and check it. Replace it as needed. Remove the seal of the air inlet. Assemble a

new or clean element.

An element can be reused if it has been properly cleaned and checked. After the cleaning,

check for the presence of breaks or tears in the filter material. The replacement must be

carried out independently from the cleanings already performed.

The pressurized air can be used to clean the elements that have not been cleaned more

than twice. Pressurized air does not remove carbon and oil build-ups.

Vacuum cleaning is a good method for paper air filters cleaning, requiring a daily cleaning

because of the dry and dusty environment they work into. Before vacuum cleaning, we

recommend to carry out the cleaning with pressurized air. Pressurized air does not remove

carbon and oil build-ups.

The washdown with nonsuding detergent is effective for the cleaning of carbon and oil build-

ups. Use a specific product to clean this kind of element. Before washdown with nonsuding

detergent, we recommend cleaning with pressurized water, pressurized air or under

vacuum.

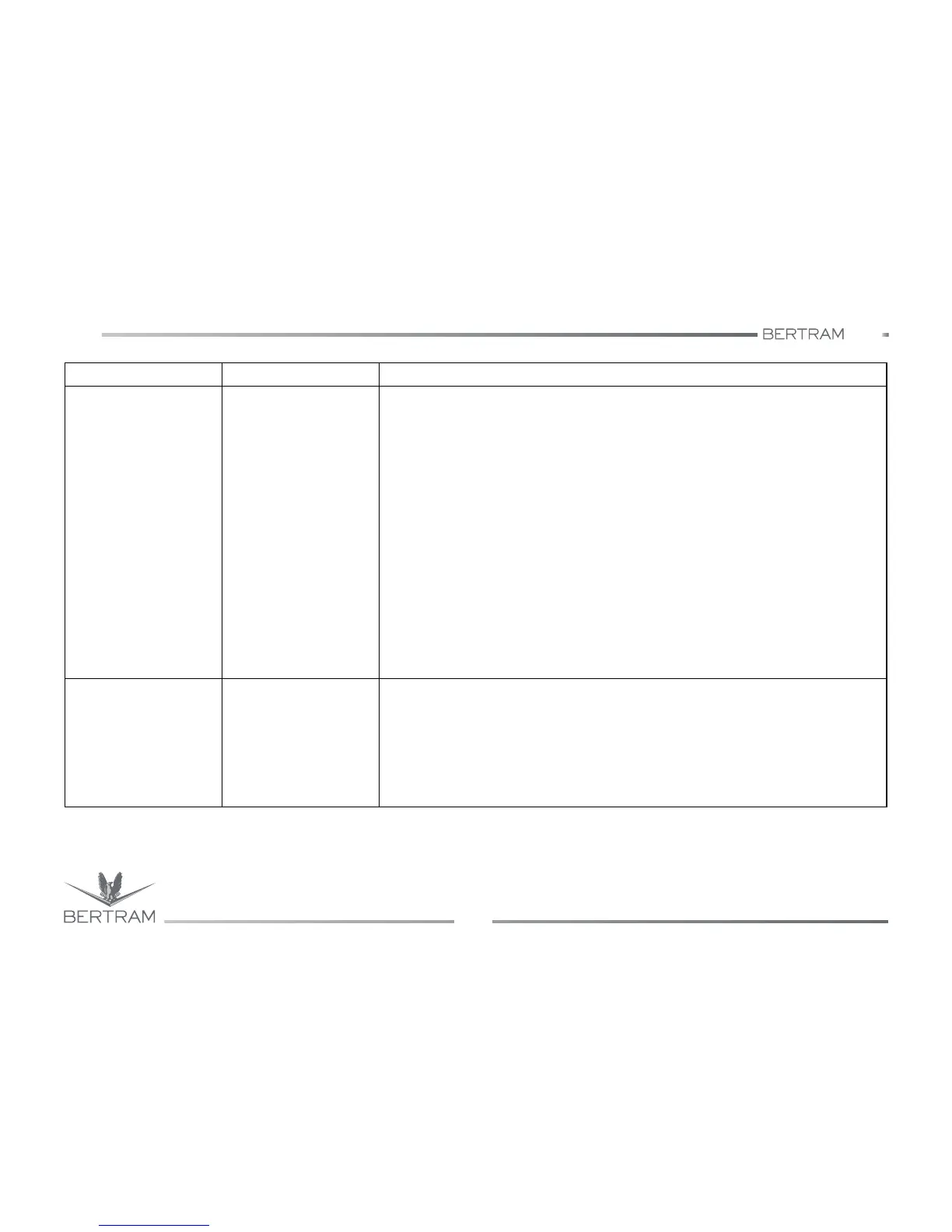

Engine oil level Check

Draining

Keep oil level between references “ADD” (Y) and “FULL” (X) on level gauge. Do not fill the

crankcase beyond “FULL” (X) reference.

Remove oil-filling plug and top up if necessary. Clean the plug and install it.

Stop the engine after running at normal operating temperature to drain the oil from the

crankcase.

Turn the knob of the drain valve counterclockwise and start the hand pump (the same used

to drain oil from the gearbox). Once the draining is completed, turn the knob clockwise to

close the valve.

Item Maintenance Notes and precautions

Loading...

Loading...