Page 79 of 113

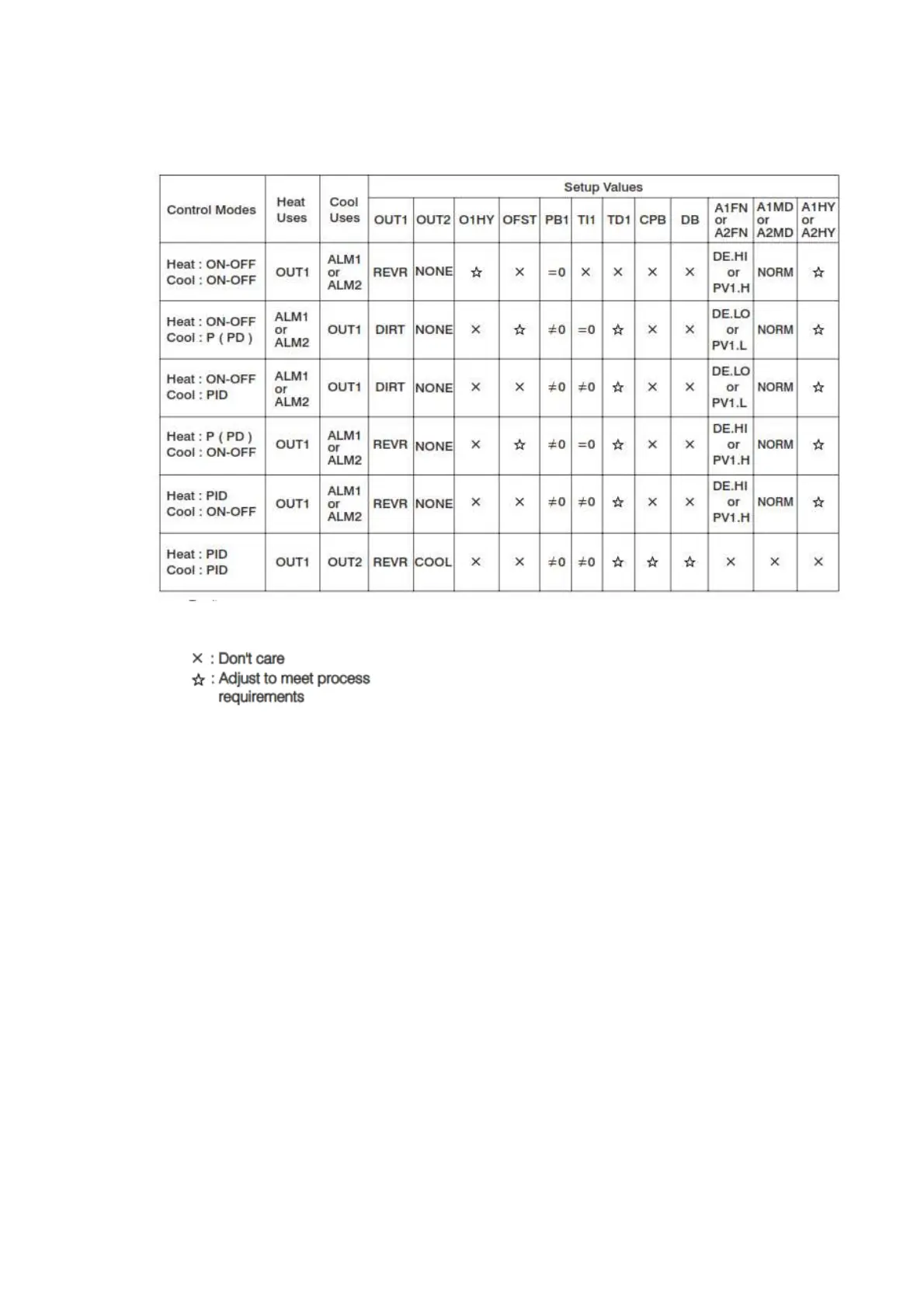

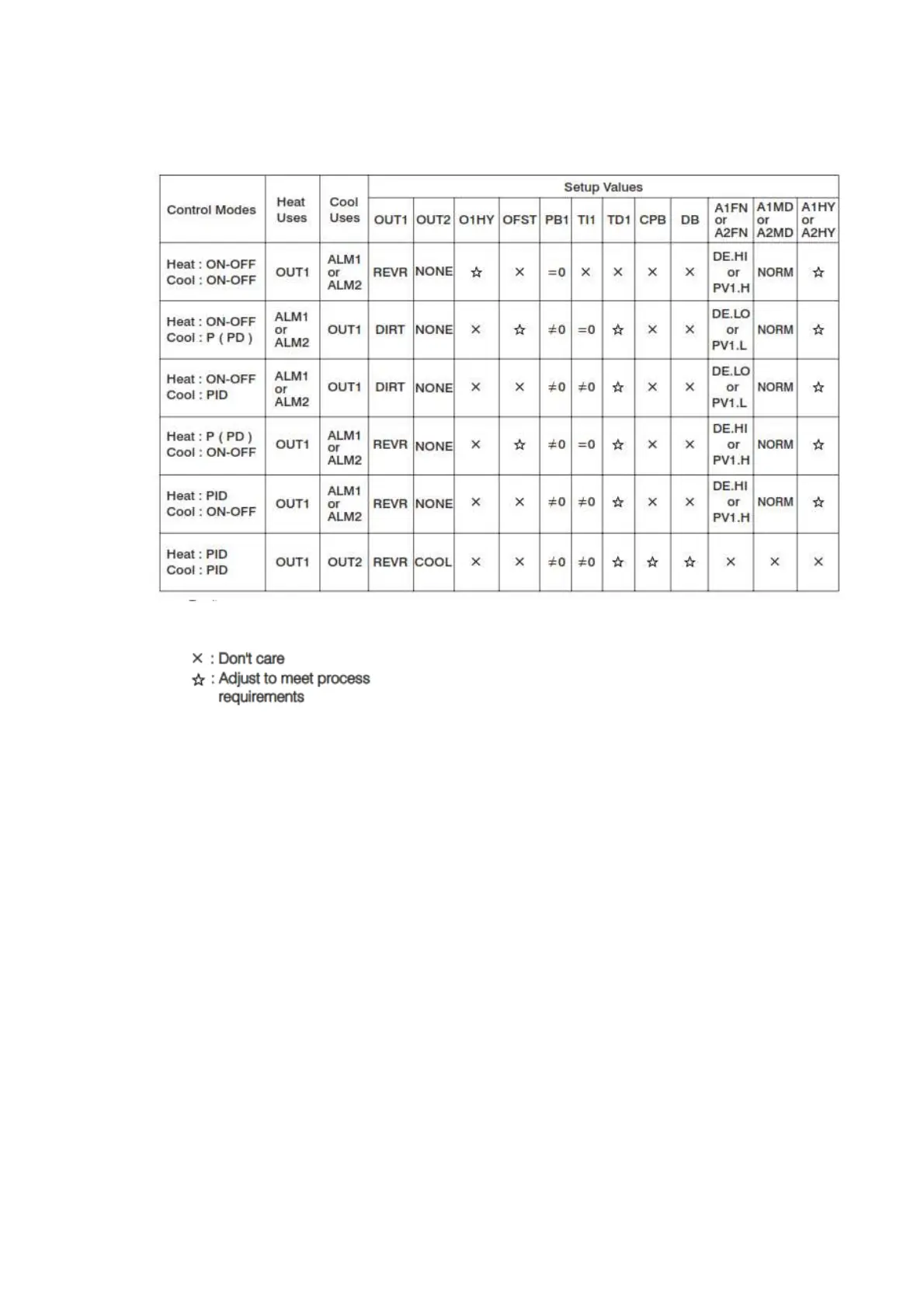

Table 4-41.Heat Cool Control Modes

Note

The ON-OFF control may result excessive overshoot and undershoot problems in the

process. The P (or PD) control will result in a deviation process value from the set point. It is

recommended to use PID control for the Heat-Cool control to produce a stable and zero offset

process value.

Other Setup Required

O1TY, CYC1, O2TY, CYC2, A2SP, A2DV,O1TY & O2TY are set in accordance with the

types of OUT1 & OUT2 installed. CYC1 & CYC2 are selected according to the output 1 type

( O1TY ) & output 2 type ( O2TY ).Generally, selects 0.5 ~ 2 sec. for CYC1, if SSRD or SSR is

used for O1TY; 10 ~ 20 sec. if relay is used for O1TY, and CYC1 is ignored if linear output is used.

Similar condition is applied for CYC2 selection.

Examples

Heat PID+Cool ON-OFF: Set OUT1= REVR, A1FN or A2FN= PV1.H, A1FN or

A2MD=NORM, A1HY or A2HY=0.1, PB1=0, TI1=0, TD1=0, and set appropriate

values for O1TY and CYC1.

Loading...

Loading...