Page 84 of 113

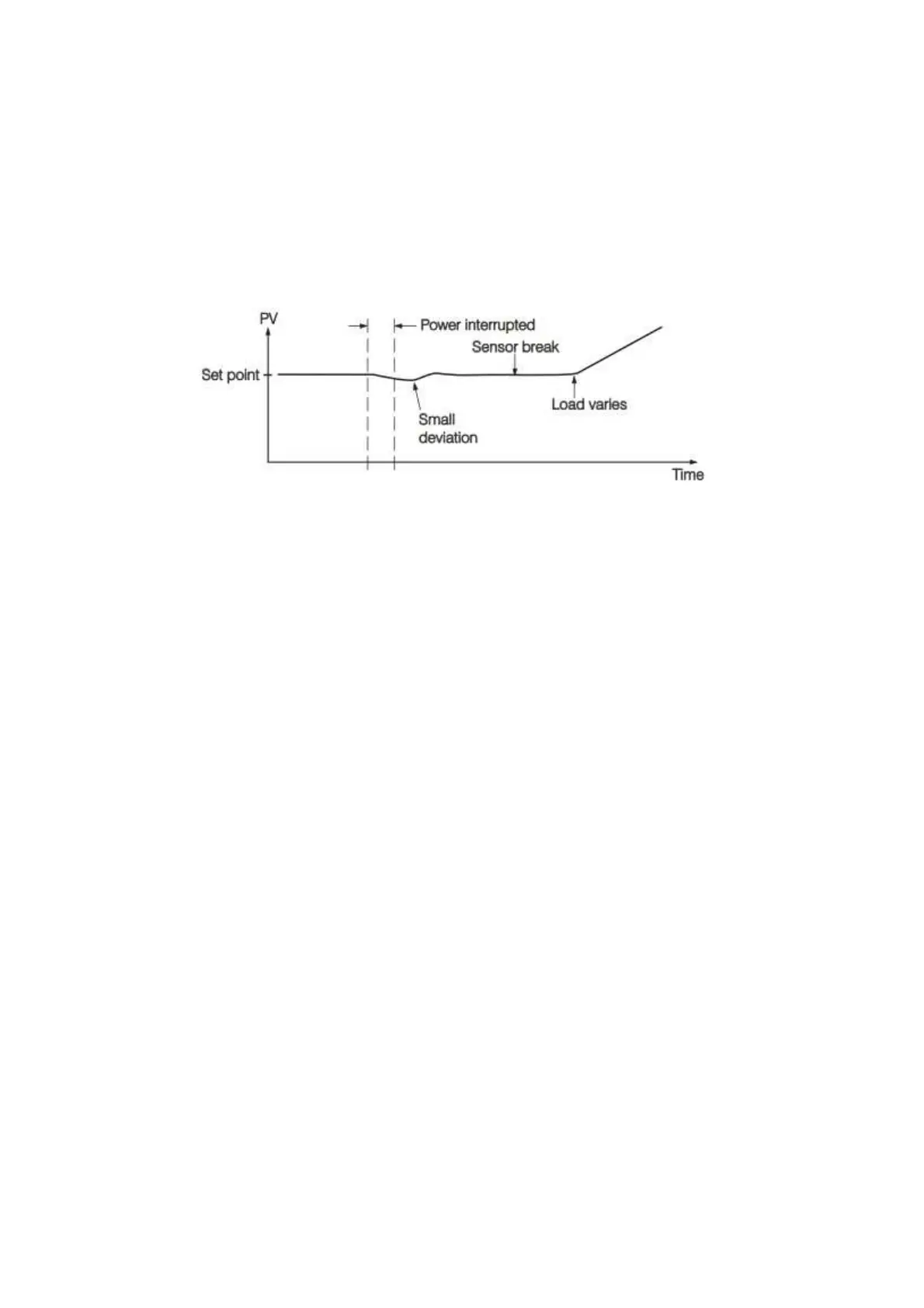

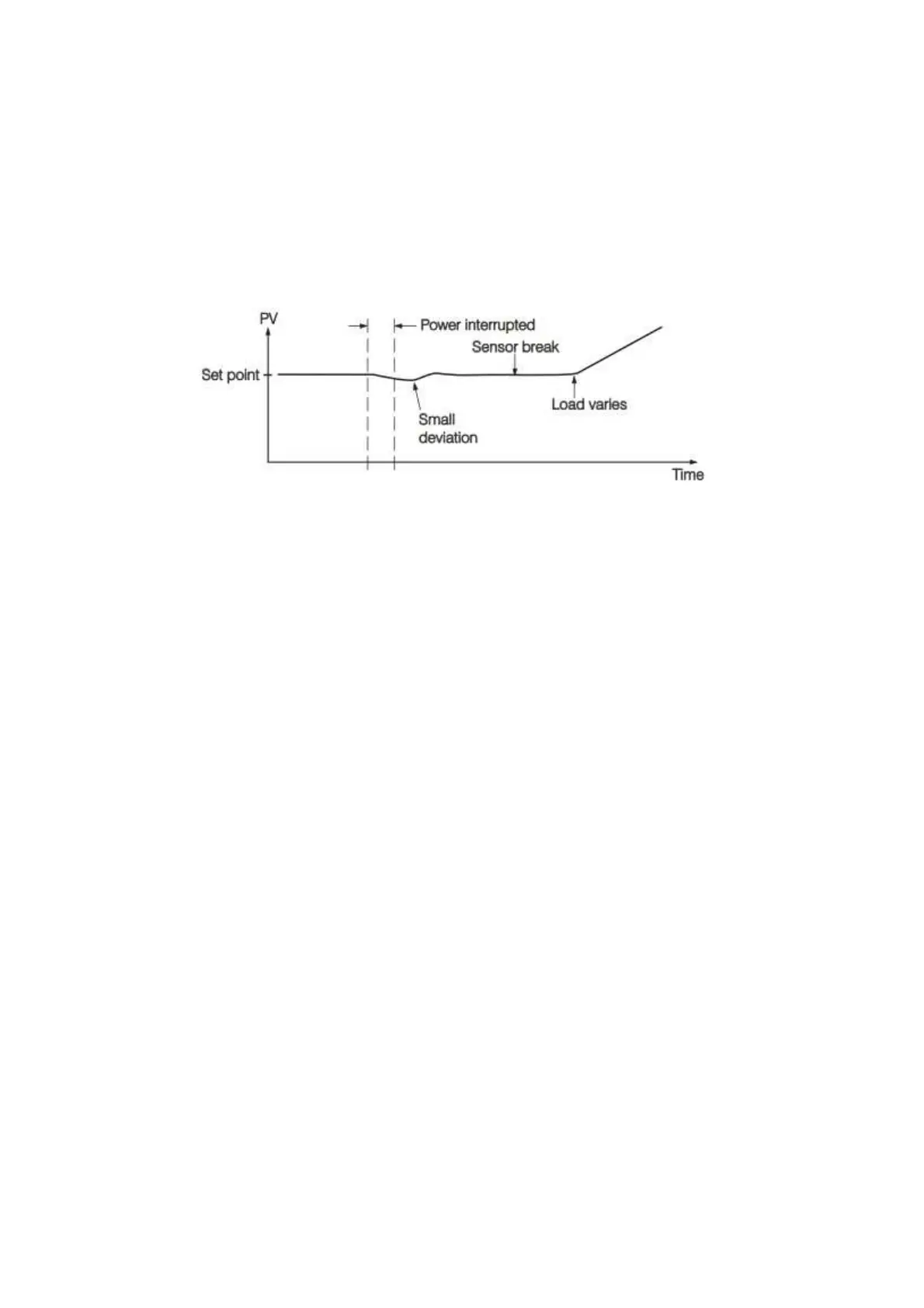

continues to control by using its previous value. If the load doesn't change, the process will remain

stable. Thereafter, once the load changes, the process may run away. Therefore, the user should

not rely on a bumpless transfer for a longer time. For fail safe reason, an additional alarm should

be used to announce the operator when the system fails. For ,a Sensor Break Alarm, if configured,

will switch to failure state and announces the operator to use manual control or take a proper

security action when the system enters failure mode.

Figure 4-32.With Bumpless Transfer

Warning: After system fails, never depend on bumpless transfer for a long time; otherwise

it might cause a problem to the system to run away.

4.3.1.1.4.9 PV1 Shift

In certain applications it is desirable to shift the controller display value from its actual

value. This can be easily accomplished by using the PV1 shift function. Press the “scroll " key to

the parameter SHIF in card parameter. The value you adjust here, either positive or negative, will

be added to the actual value. The SHIF function will alter PV1 only.

Here is an example. A process is equipped with a heater, a sensor and a subject to be

warmed up. Due to the design and position of the components in the system, the sensor could not

be placed any closer to the part. Thermal gradient (different temperature) is common and

necessary to an extent in any thermal system for heat to be transferred from one point to another.

If the difference between the sensor and the subject is 35 C, and the desired temperature at the

subject to be heated is 200 C, the controlling value or the temperature at the sensor should be 235

C. You should input -35 C as to subtract 35 C from the actual process display. This in turn will

cause the controller to energize the load and bring the process display up to the set point value

Loading...

Loading...