2-90

Confidential

4.2.4 Multiple sheets of paper are fed

< User Check >

- Check that too much paper is not loaded in any paper tray.

- Check if the paper is loaded into each paper tray correctly.

- Turn back the paper loaded in each paper tray or change the orientation of the paper by

180°.

- Check if the thickness of each paper is 60 to 105 g/m

2

. (60 to 163 g/m

2

for MP tray.)

- Fan the stack of paper well and reinsert the papers into each paper tray.

4.2.5 Paper becomes wrinkled

< User Check >

- Check if the paper is loaded into each paper tray correctly.

- Turn back the paper loaded in each paper tray or change the orientation of the paper by 180°.

- Adjust the paper guide corresponding to the paper size.

- Check if the thickness of the paper is 60 to 105 g/m

2

. (60 to 163 g/m

2

for MP tray.)

- Check if paper is not damp.

- Check that no dust adheres to the fuser unit.

- Check whether the paper type is appropriate.

4.2.6 Paper is fed at an angle

< User Check >

- Check if the paper is loaded into each paper tray correctly.

- Turn back the paper loaded in each paper tray or change the orientation of the paper by 180°.

- Adjust the paper guide corresponding to the paper size.

- Check if the thickness of the paper is 60 to 105 g/m

2

. (60 to 163 g/m

2

for MP tray.)

- Check that too much paper is not loaded in the paper tray.

- Check whether the paper type is appropriate.

- Clean each paper pick-up roller.

- Check if only the one side of the envelope lever is lowered.

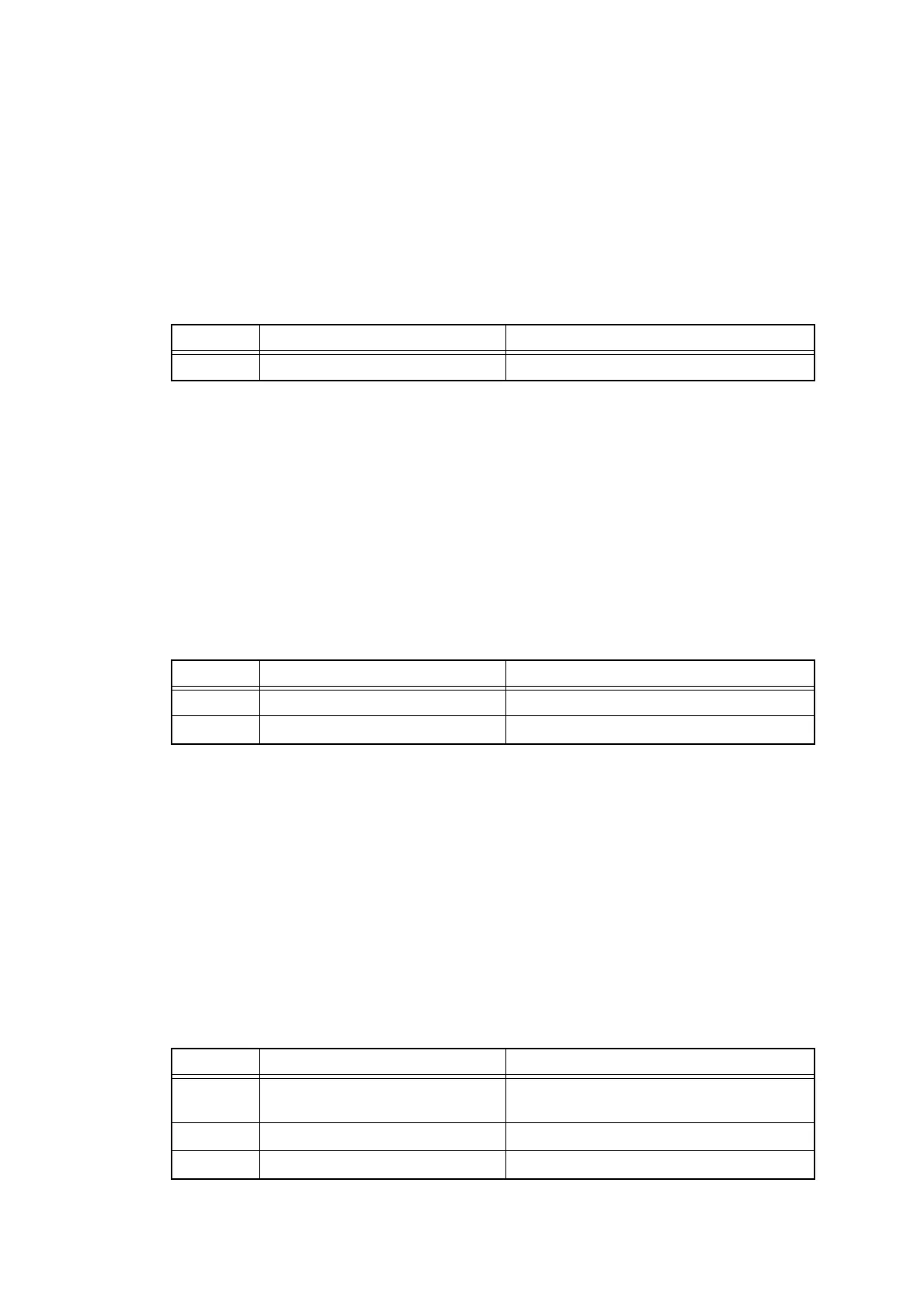

Step Cause Remedy

1 Separation pad worn out Replace the appropriate PF kit.

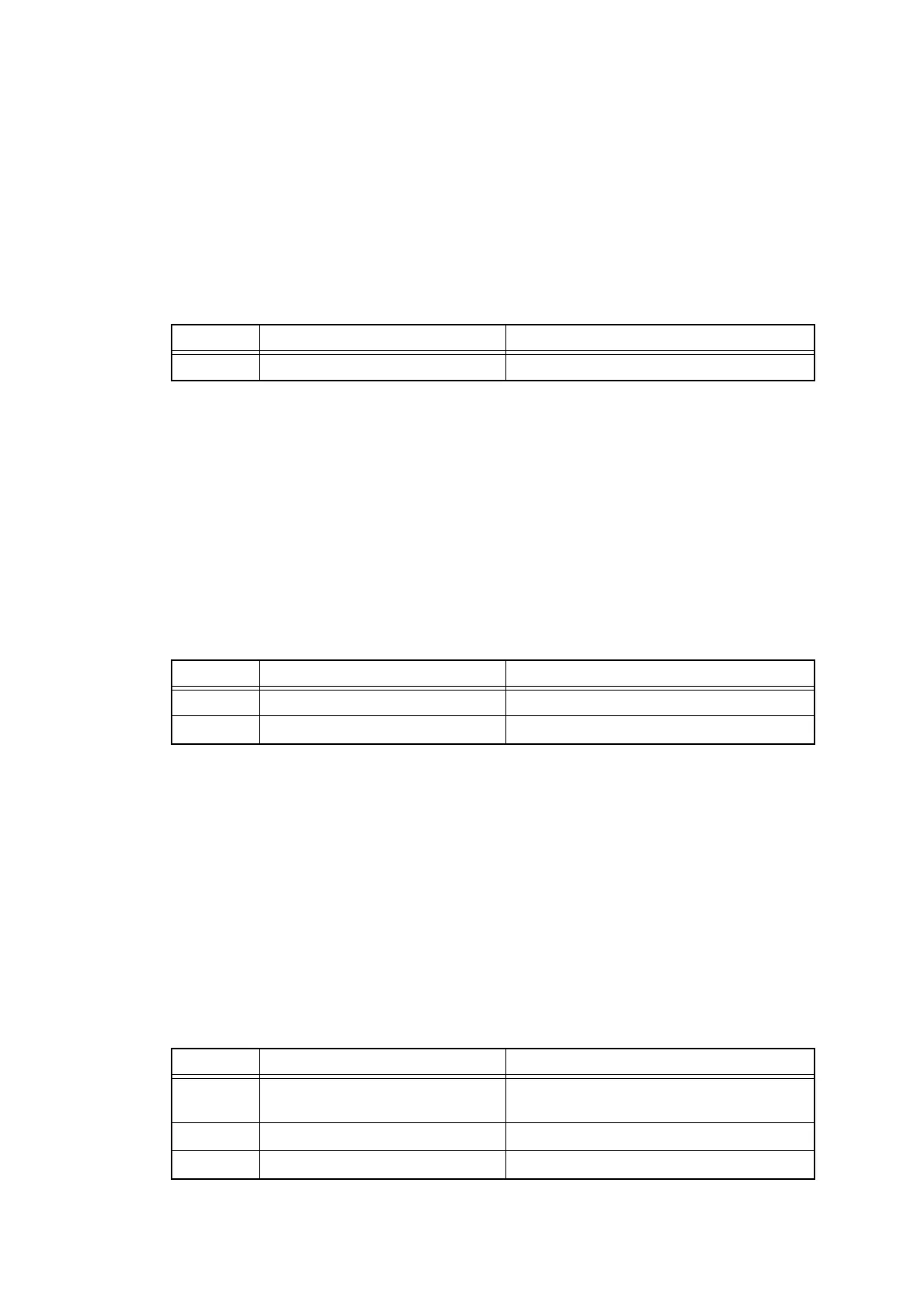

Step Cause Remedy

1 Paper eject ASSY failure Replace the paper eject ASSY.

2 Fuser unit failure Replace the fuser unit.

Step Cause Remedy

1 Uneven worn-out of each paper

pick-up roller

Replace the appropriate PF kit.

2 Paper feed unit failure Replace the paper feed unit.

3 Main PCB failure Replace the main PCB ASSY.

Loading...

Loading...