9

8175

ENGLISH

INSTALLATION

3.1 GENERAL INSTALLATION GUIDELINES

Prior to the installation of the 8175 ultrasonic level transmitter, a clear mounting

location for the product must be determined.

● The level transmitter or sensor types 8175 / 8170 are designed for

liquid level measurement. It is the user responsability to test the

functionality of the device for any other material such as powders,

granuals etc.

● The 8175 ultrasonic level transmitter or sensor must be installed

perpendicular to the process medium.

● Ensure a minimum distance of 30 cm between the level of the fluid

and the sensor is respected.

The tank or vessel should be surveyed to locate potential obstructions which

may interfere with the beam cone. Such obstructions may include: fill pipes and

streams; mixers and agitators; tank side walls and rungs.

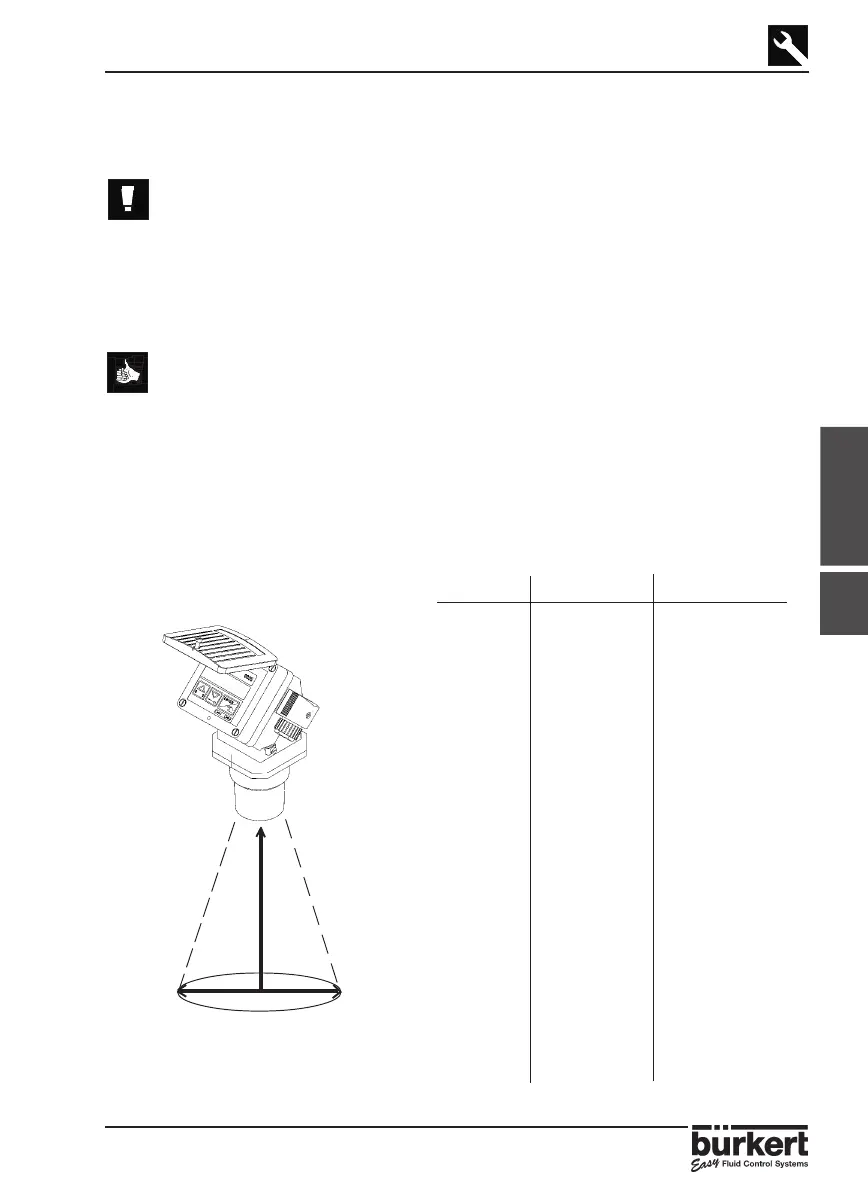

3.1.1 Beam cone diameter

The ultrasonic level transmitter type 8175 generates 8 pulses per second which is

emitted from the base of the transducer. As the pulses leave the transmitter, they

expand to an 8° beam angle until they are reflected back via the process medium.

To determine the maximum diameter of the beam cone for the application select the

maximum length (L) from the table below.

Fig. 3.1 Length and Diameter

Relationship

Diameter (D cm)

8°

Length (L cm)

Min 30 cm

3.1

LD L DL D

30 4 360 50 690 96

40 6 370 52 700 98

50 7 380 53 710 99

60 8 390 55 720 101

70 10 400 56 730 102

80 11 410 57 740 103

90 13 420 59 750 105

100 14 430 60 760 106

110 15 440 62 770 108

120 17 450 63 780 109

130 18 460 64 790 110

140 20 470 66 800 112

150 21 480 67 810 113

160 22 490 69 820 115

170 24 500 70 830 116

180 25 510 71 840 117

190 27 520 73 850 119

200 28 530 74 860 120

210 29 540 76 870 122

220 31 550 77 880 123

230 32 560 78 890 124

240 34 570 80 900 126

250 35 580 81 910 127

260 36 590 83 920 129

270 38 600 84 930 130

280 39 610 85 940 131

290 41 620 87 950 133

300 42 630 88 960 134

310 43 640 90 970 136

320 45 650 91 980 137

330 46 660 92 990 138

340 48 670 94 1000 140

350 49 680 95

Loading...

Loading...