Carefully bend the tubing in the middle

according to the diagram below. DO NOT

bend the tubing more than 90° or more t

han 3 times.

NOTE: DO NOT intertwine signal cable

with other wires. While bundling these

items together, do not intertwine or cross

the signal cable with any other wiring.

6. REFRIGERANT PIPING CONNECTION

7GB-14

4. Remove PVC tape from ends of pipe

when ready to perform flaring work.

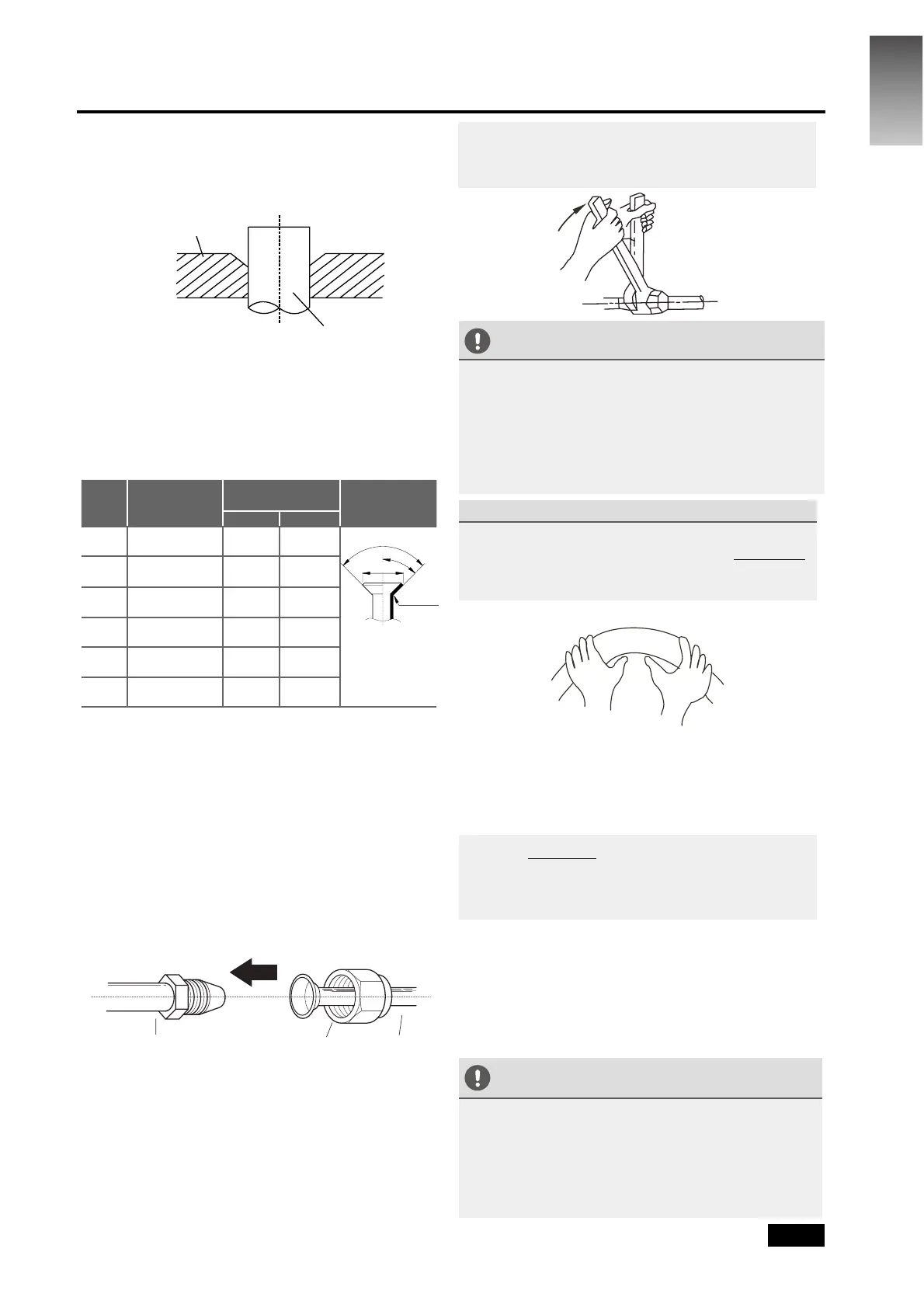

5. Clamp flare form on the end of the pipe.

The end of the pipe must extend beyond

the flare form.

Flare form

Pipe

Fig. 6.4

6.

Place flaring tool onto the form.

7. Turn the handle of the flaring tool

clockwise until the pipe is fully flared.

Flare the pipe in accordance with the

dimensions shown in table 6.1.

Table 6.1: PIPING EXTENSION BEYOND FLARE

FORM

Pipe

gauge

Tightening

torque

Flare dimension (A)

(Unit: mm)

Flare shape

Min. Max.

Ø 6.4

14.2-17.2 N.m

(144-176 kgf.cm)

8.3 8.3

R0.4~0.8

45

°

±

2

90

°

±

4

A

Fig. 6.5

Ø 9.5

32.7-39.9 N.m

(333-407 kgf.cm)

12.4 12.4

Ø 12.7

49.5-60.3 N.m

(504-616 kgf.cm)

15.4 15.8

Ø 15.9

61.8-75.4 N.m

(630-770 kgf.cm)

18.6 19

Ø 19.1

97.2-118.6 N.m

(990-1210 kgf.cm)

22.9 23.3

8. Remove the flaring tool and flare form,

then inspect the end of the pipe for

cracks and even flaring.

Step 4: Connect pipes

Connect the copper pipes to the indoor unit

first, then connect it to the outdoor unit. You

should first connect the low-pressure pipe,

then the high-pressure pipe.

1. When connecting the flare nuts, apply

a thin coat of refrigeration oil to the

flared ends of the pipes.

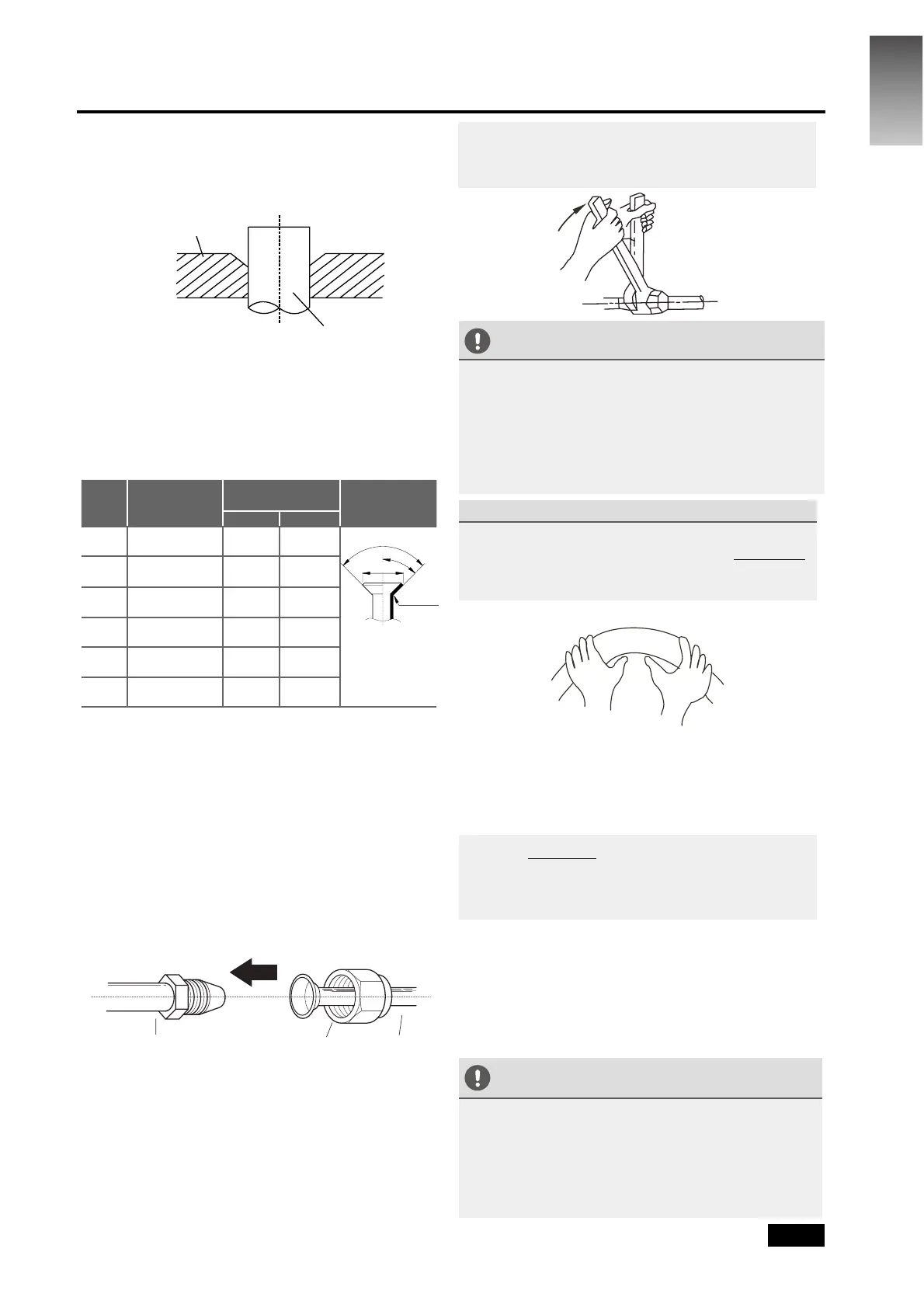

2. Align the center of the two pipes that

you will connect.

Indoor unit tubing

Flare nut

Pipe

Fig. 6.6

3. Tighten the flare nut as tightly as

possible by hand.

4. Using a spanner, grip the nut on the unit

tubing.

5. While firmly gripping the nut, use a

torque wrench to tighten the flare nut

according to the torque values in table

7.1.

NOTE: Use both a spanner and a torque

wrench when connecting or disconnecting

pipes to/fromthe unit.

Fig. 6.7

CAUTION

• Ensure to wrap insulation around the

piping. Direct contact with the bare piping

may result in burns or frostbite.

• Make sure the pipe is properly connected.

Over tightening may damage the bell

mouth and under tightening may lead to

leakage.

NOTE ON MINIMUM BEND RADIUS

Bend the pipe with thumb

min-radius 10cm (3.9”)

Fig. 6.8

6. After connecting the copper pipes to

the indoor unit, wrap the power cable,

signal cable and the piping together

with binding tape.

7. Thread this pipeline through the wall

and connect it to the outdoor unit.

8. Insulate all the piping, including the

valves of the outdoor unit.

9. Open the stop valves of the outdoor

unit to start the flow of the refrigerant

between the indoor and outdoor unit.

CAUTION

Check to make sure there is no refrigerant

leak after completing the installation work.

If there is a refrigerant leak, ventilate the

area immediately and evacuate the system

(refer to the Air Evacuation section of this

manual).

Ø 22

109.5-133.7 N.m

(1117-1364 kgf.cm)

27 27.3

GB

Loading...

Loading...