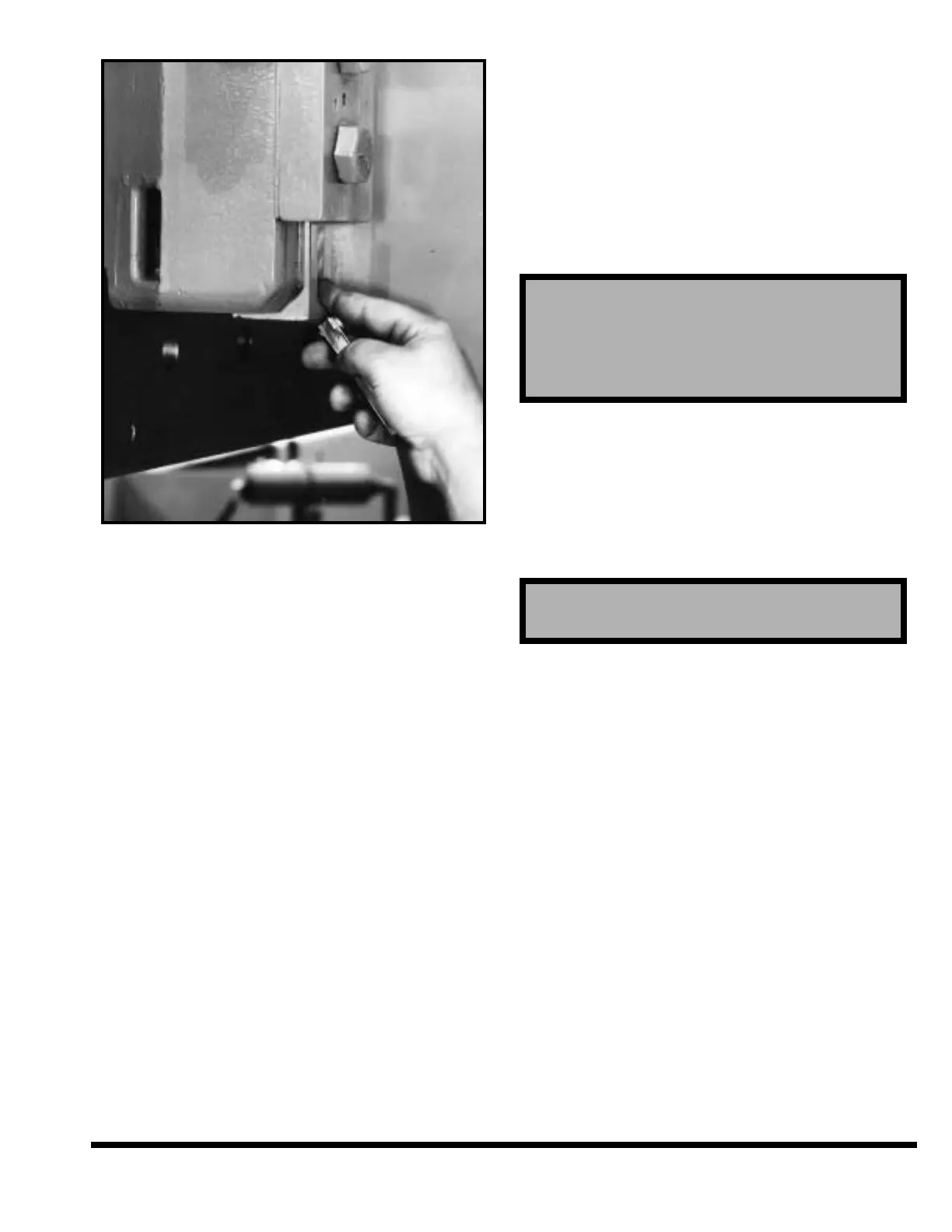

FIGURE 2-7 – Checking slide clearance

Regardless of level of the bed, if this condition is not

corrected the slides may score. Raise or lower the

rear of either housing to relieve twist in machine.

Some clearance must appear at the points which

have been tight.

These slide clearances are considered to be

the final and most important check on the

level of the machine since they are actual

running clearances.

After the machine is level, retighten foundation bolt

nuts securely. Recheck slide clearances. Do not

remove shims. Alignment may not be permanent,

recheck level in a few weeks. Do not use any grout-

ing around the machine. Leave the bed pit empty

and cover with steel plate.

HYDRAULIC RESERVOIR

Remove pipe plug from auxiliary cover plate and

install the air breather. Remove shipping caps and

install filler / breathers.

The hydraulic reservoirs are equipped with a drain

valve. See Figure 1-2. Before starting machine,

crack this valve open. Water may have collected in

the tank during shipment. If no water comes out, or

when oil starts coming out, close the valve secure-

ly. Repeat this check monthly.

LUBRICATION

Proper lubrication is of extreme importance to your

machine. The following lubrication points should

be checked before start-up and at regular intervals

thereafter.

1. Hydraulic Reservoir: Before starting machine

check for proper fluid level at the oil sight gage.

See Figure 1-2. Fluid level must be checked

with the ram at the top of the stroke.

2. Cylinder Clevis Pins: Lubricate while cycling ram

under load, such as obtained with a bumping die.

Lubricate once a week for the first six weeks and

once a month thereafter. Use a #2 lithium base

grease with “moly” additive (C.I. grease H-2M).

This must be done after electrical connections

are made and the machine is running.

3. Ram Slides: The ram slides (Figure 1-1) are

automatically lubricated with clean, filtered oil

from the hydraulic system. When stroking the

ram, oil is forced through metering fittings on

each ram guide. Before starting the press

brake, the exposed part of guides should be

wiped clean and oiled.

ELECTRICAL CONNECTION

Suitable electrical leads must be brought to the

machine as shown on certified Foundation Plan

drawing. These leads are connected to incoming

side of electrical disconnect switch in main electri-

cal enclosure. Be certain that leads are of sufficient

capacity and that proper voltage is fed to the

machine. CINCINNATI INCORPORATED equipment

requires that the incoming line supply at the

machine does not vary more than plus or minus

10% from the nominal. Some installations may

require additional line conditioning, other than

supplied with the machine controls. Contact

CINCINNATI INCORPORATED Service Department

for further information.

CAUTION

Keep clear of the moving ram.

CAUTION

Standard machines are designed for and

shipped with petroleum-based hydraulic

fluid, which is flammable. Check applicable

fire codes for special precautions.

2-7

Loading...

Loading...