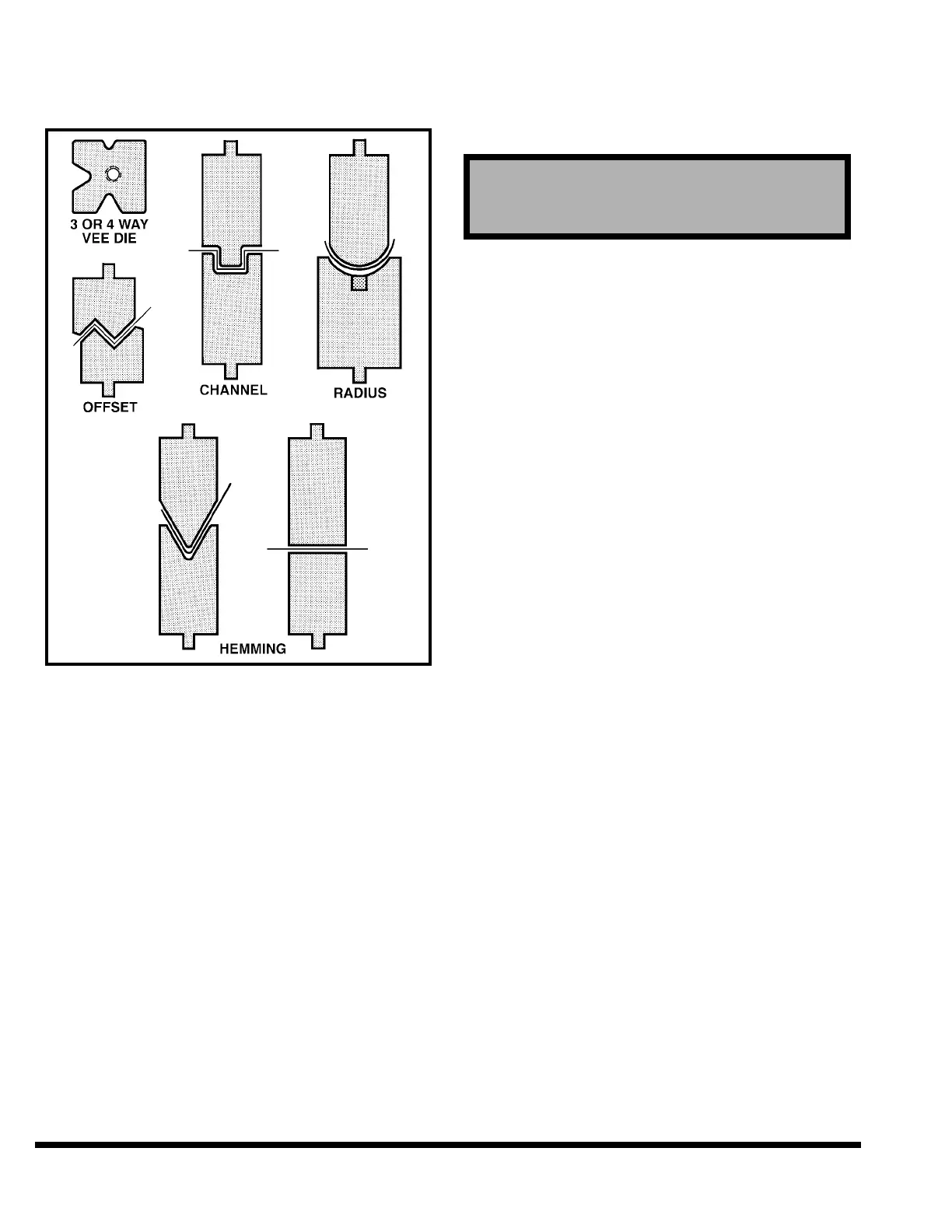

CINCINNATI INCORPORATED can provide many

other types of standard and special dies, some of

which are shown in Figure 5-4.

FIGURE 5-4 – Types of dies

DIE SETS: Special care and precautions should be

taken when operating die sets with guide pins

and bushings.

Depending on the working height of the die set,

the full stroke return may cause the die set

guide pins and bushings to separate. Re-entry of

the guide pins into the bushings may be difficult,

if not impossible. Each die set application should

be reviewed for this condition.

CINCINNATI INCORPORATED recommends that

the working height of all die sets be such that the

bushings never leave the guide pins when the

ram makes a full up stroke.

TOOL INSTALLATION

To install the tooling, use the following procedure:

✦ Turn “ON” the main disconnect switch.

✦ Depress MAIN DRIVE - START pushbutton on

FM Control Station (Figure 6-1).

✦ Turn OPERATOR CONTROL selector to “ON”

position.

✦ Use MODE SELECT to place machine in “SET-

UP” mode.

SETUP mode is used to run the ram down

using the Palmbutton Operator Station, and

up using the RAM UP button. This mode is to

be used only for positioning the ram under no-

load conditions.

✦ If the ram is not at maximum “up” position,

depress RAM UP button on Palmbutton Opera-

tor Station to raise ram. Ram will move to the

maximum “up” position and stop. When the

ram stops, continue with the next step.

✦ Turn the OPERATOR CONTROLS selector on

the FM Control Station to “OFF” position and

remove the key to prevent ram movement.

✦ If the filler block has not already been installed,

deburr, clean and lightly oil bed top. Place nuts

for filler block screws in proper bed cross slots.

Place filler block (die holder) on bed and lightly

bolt in place. At this time, also install optional

die aligners (3 front and 3 back) to the front and

back of the bed. In some cases a filler block may

not be required and die may be placed directly

on the bed. Deburr, clean and lightly oil the top

of filler block. Loosen all of the filler block set

screws.

✦ Measure the height of the lower die and upper

die together. Turn the Operator Controls Selec-

tor on the FM Control Station to “ON”. Lower

the ram to a height above the filler block equal

to the die height plus 1/4”. Turn the Operator

Controls Selector to “OFF” and remove key.

✦ Insert lower die on the filler block. Leave it

extended past end of bed several inches. Visu-

ally center filler block so lower die is aligned

with slot in the ram nose.

✦ Loosen all ram die clamp nuts about .125”

(3.2mm).

✦ Rest the upper die on extended portion of lower

die. Make sure tongue of upper die is in the ram

nose slot and that the upper die is trapped by

the lower die and ram die slot. See Figure 5-5.

Then slide upper die into lengthwise position

with the lower die. Slide the set of dies into a

centered position on the machine.

CAUTION

Before proceeding, read guidelines in SAFETY

Section for installing tooling.

5-2

Loading...

Loading...