UNLOADING

After receiving your CINCINNATI FM Hydraulic

Press Brake, carefully remove the contents of the

one or more boxes shipped with the machine. In

these boxes are all of the machine’s optional acces-

sories and small parts, such as wrenches and lev-

eling shims. Check all of the parts in the boxes with

the packing list. Claims for shortages should be

made within ten days.

Leave the shipping skids attached to the machine

until it has been moved to its final location.

The 400FM through 14' machines are typically

shipped assembled on skids. The bed is mounted

on the back of the housings. Due to weight or

height limitations, longer machines or machines

with special main members, are typically shipped

disassembled.

400FM x 16' and larger machines are typically

shipped disassembled. Each of the five main mem-

bers can be handled by a crane of sufficient

capacity with chains or cables of adequate size

(refer to American National Standards Institute

B30.9). Shipping weights of the five members

(right housing, left housing, bed, ram and housing

brace) are clearly listed on the Bill of Lading for

the shipment. Check these weights carefully

before lifting or handling.

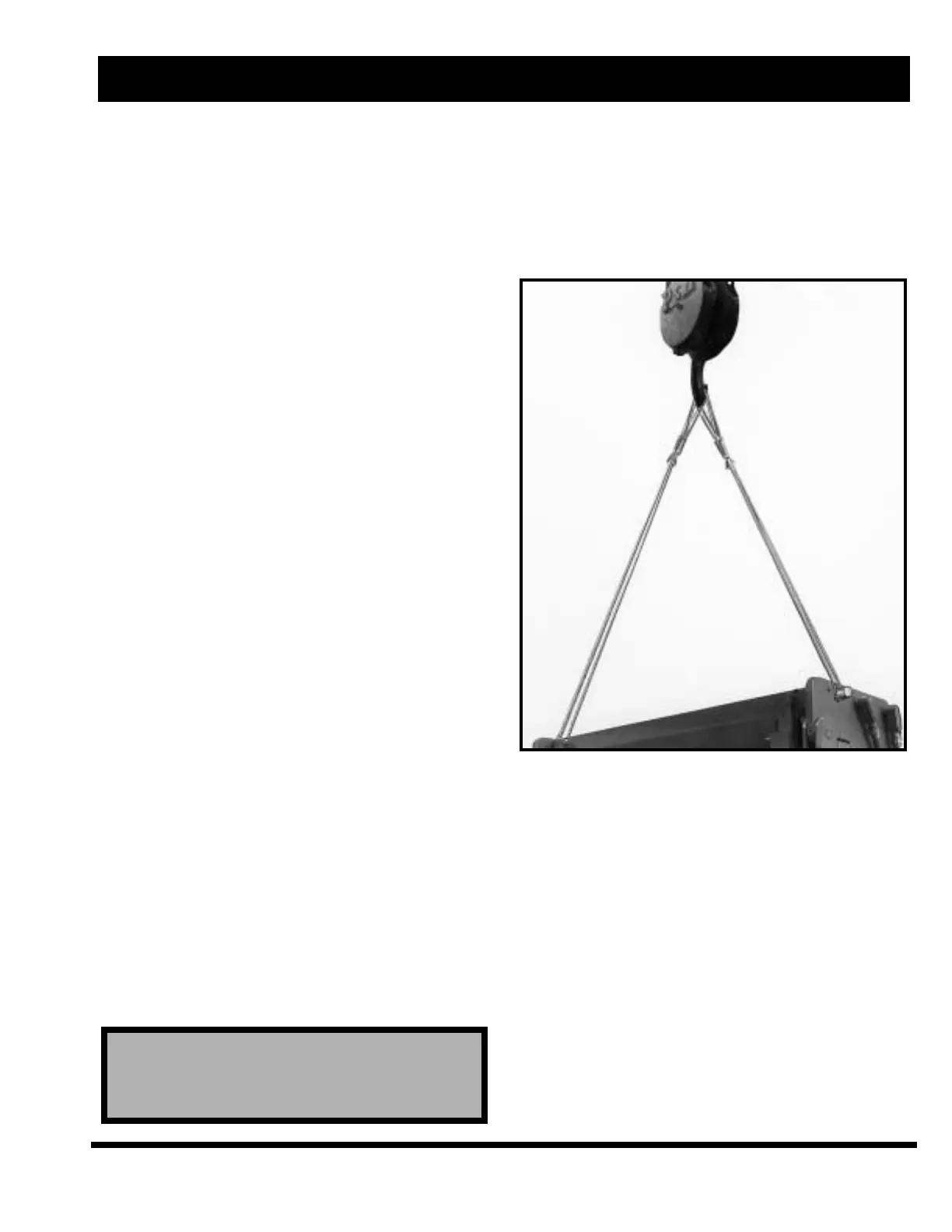

LIFTING AND MOVING

CINCINNATI INCORPORATED recommends that

professional riggers be employed to handle the

machine. They are experienced in safe handling

and will minimize risk of damage to the machine.

The assembled machines can be handled by cranes

of sufficient capacity. Use chains or cables adjust-

ed to the proper length for even lifting. The chains

or cables should be long enough to minimize the

side loading on the housings. If short cables are

used, fit a spreader beam between the housings

near the lifting holes. A typical hitch is shown in

Figure 2-1.

Where your crane does not have sufficient capacity,

or no crane is available, rig the machine into final

location. When rigging assembled machines into

position, leave the bed attached to the back of the

housing. If jacks are used to lower the press brake

onto the foundation bolts, care should be taken to

prevent twisting of the machine.

FIGURE 2-1 – Lifting the machine

Disassembled machines can be lifted directly from

the vehicle if crane capacities are sufficient. The

right and left housings should be lifted by the

lifter hole as shown in Figure 2-2. If a clevis as

shown is not available, an adequate strength cable

should be used in the same housing hole. The bed

and ram should be lifted with a cable through the

large lifting holes. Be sure to protect finished sur-

faces from damage.

Where crane capacities are not sufficient or avail-

able, the five main members can be handled by

using jacks, roller bars and a mobile crane. Care

should be taken to prevent damage to finished

surfaces and parts attached to main members of

the machine.

! W

! W

ARNING !

ARNING !

BE EXTREMELY CAREFUL TO KEEP MACHINE

SUPPORTED EVENLY AND TO GUARD AGAINST

TIPPING.

EM-446 (N-08/99)

2-1

SECTION 2 INSTALLATION

Loading...

Loading...