necessary to obtain the proper flange dimen-

sion, enter the positive or negative value in

this field. A negative value moves the back-

gage toward the tooling. A positive value

moves the backgage away from the tooling.

The bend allowance can also be used as a

“finger offset” to compensate for non-standard

gage finger lengths or for gaging on the shelf

of a .25” finger.

Valid Range: -0.999 - +0.999

Entry Format: 0.XXX English or X.XX Metric

Default Value: 0.000

GA. PAUSE (Gage Pause): This value repre-

sents the amount of time in seconds the back-

gage will delay at the current step position or

retracted position before advancing to the next

step programmed position. The pause timer

starts after the ram returns to the top of

stroke. When a gage pause time is non-zero,

the gage will not move forward (towards the

dies) to the next step position until the ram has

returned to the top of stroke and the gage

pause timer has expired. If the gage pause time

is programmed to zero, the gage will move

backward or forward at the bottom of the

stroke, depending on the next step pro-

grammed position.

Valid Range: 0.0 - 9.9

Entry Format: X.X

Default Value: 0.1 ==> Gage will not move to

next step until ram has returned to top of stroke

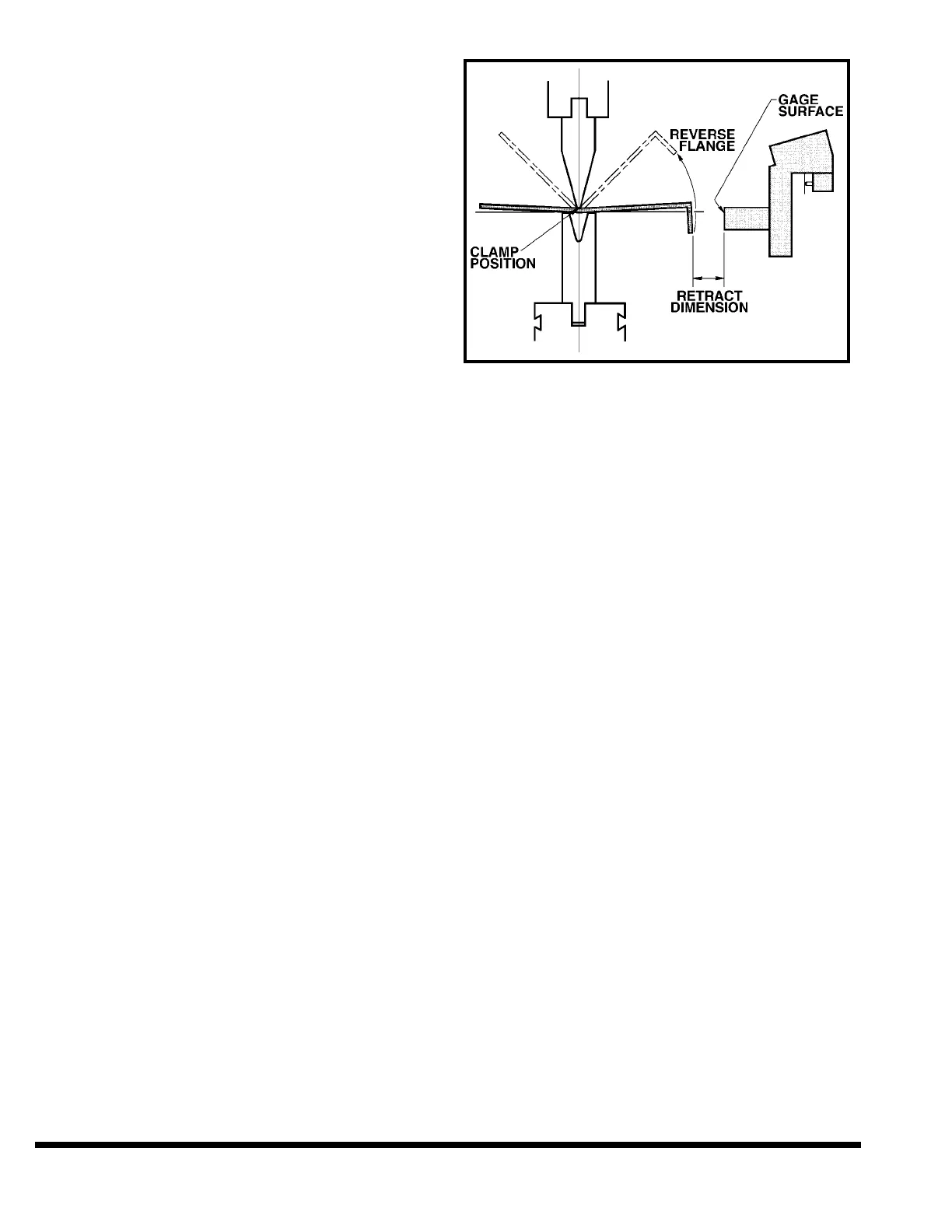

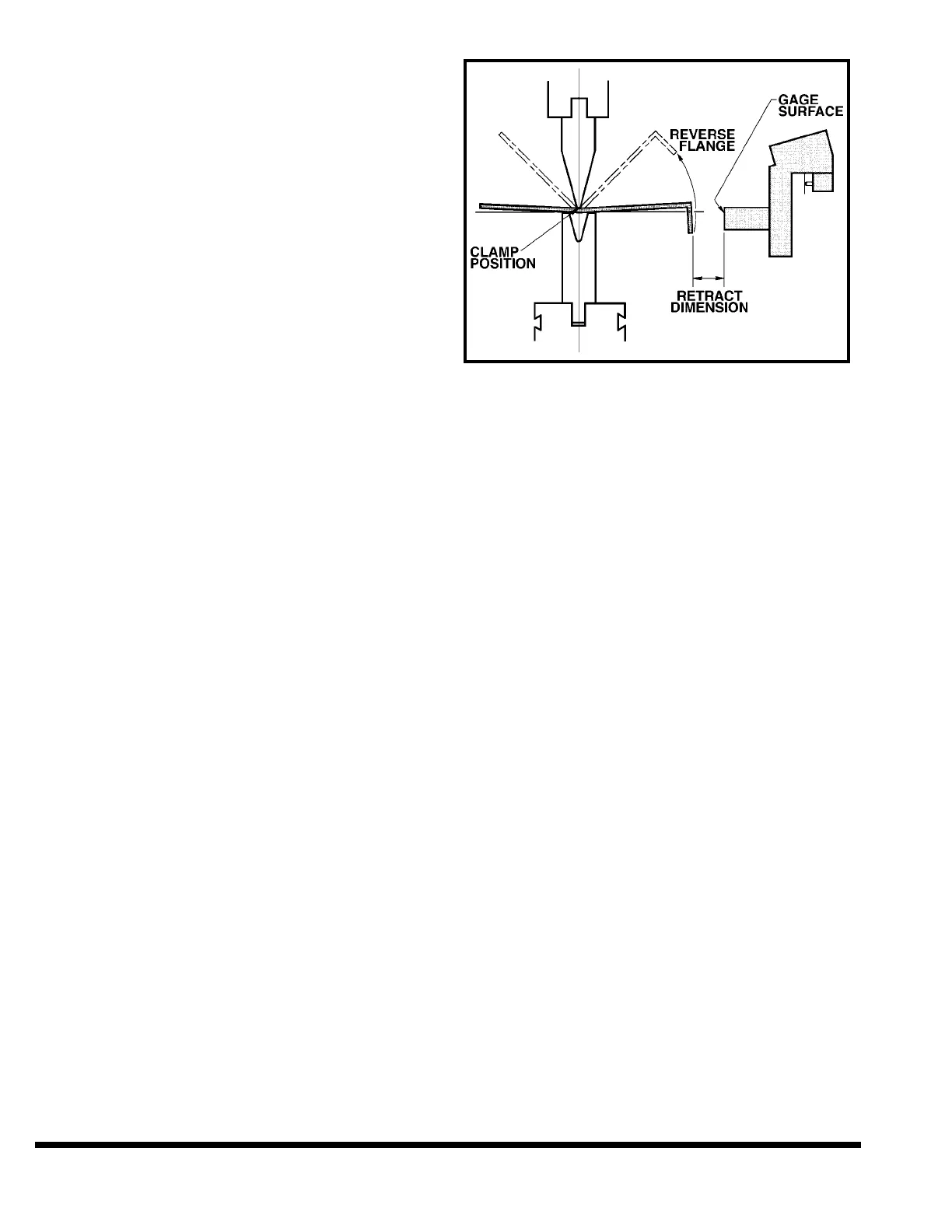

RETR DIS (Retract Distance): This value is

the distance the gage will move back from the

programmed flange dimension once the ram

has reached the clamp position (see CLAMP

POSITION). See Figure 7-5. It is used to pro-

vide clearance during the bend between the

workpiece and the gage surface when the part

has a reverse flange. If the value entered

results in a retract position greater than the

maximum gage travel then the gage will only

retract to the maximum travel without gener-

ating an error. If the ram reaches the bottom

of the stroke before the clamp position, the

gage will retract at reversal. The gage will

move to either the retract position or the next

step flange dimension, whichever is further

from the dies.

Valid Range: 0.000 - X Max Dimension

Entry Format: XX.XXX English or XXXX.XX

Metric

Default Value: 0.000

FIGURE 7-5 – Clamp and Retract

CLAMP: This function is used in conjunction

with the ram CLAMP POSITION and the gage

RETRACT DISTANCE. When the CLAMP func-

tion is ON, the control stops the ram on the

down stroke at the programmed CLAMP POSI-

TION. The operator must then release and reac-

tivate the palmbutton or footswitch to continue

the bend. If a retract distance has been pro-

grammed, the backgage will retract away from

the workpiece when the ram reaches clamp

position.

If the CLAMP function is set to PAUSE, the ram

will hesitate for a moment at the clamp position

while the gage retracts, then continue on. It is

not necessary to release and reactivate the oper-

ator controls when PAUSE is selected.

When the CLAMP function is off, the ram will not

stop at the clamp position but the gage will

retract as the ram passes the CLAMP POSITION.

To select the CLAMP function, use the arrow

keys to highlight the CLAMP field. Press the “Off”

softkey’s button to turn the clamp stop off. Press

the “On/Pause” softkey’s button to toggle

between ON and PAUSE.

FRONT PANEL SETTINGS

There are two functions on the front panel of the

control which are programmed on a per step

basis. These are the FORM SPEED SELECT and

the STROKE STOPS. The setting of these two

functions are not indicated on the display itself.

Instead the setting is indicated by an LED under

the specific function. When changing steps the

LED’s will change to reflect the programmed set-

ting for that step.

7-8

Loading...

Loading...