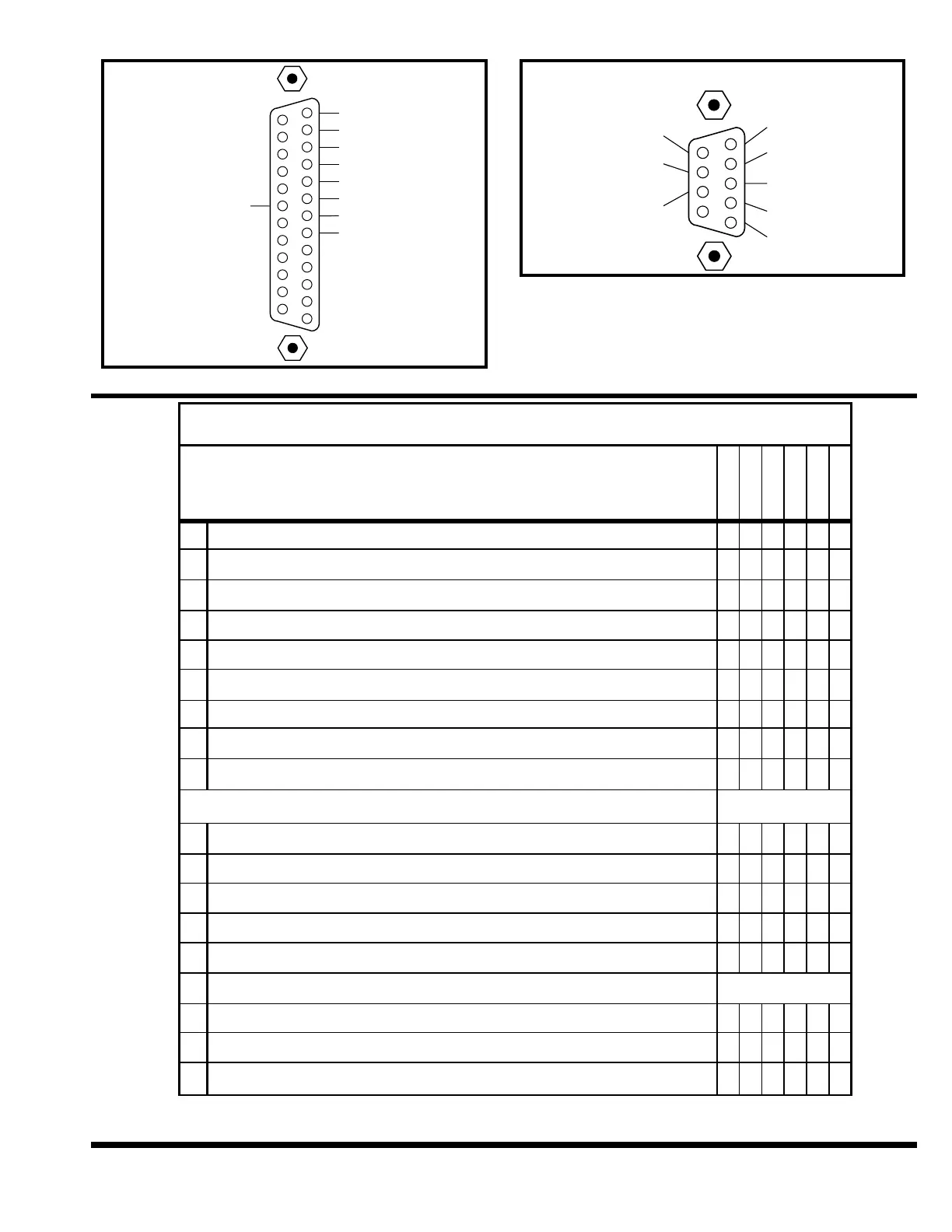

FIGURE 9-21 – PC 25-Pin Serial Port

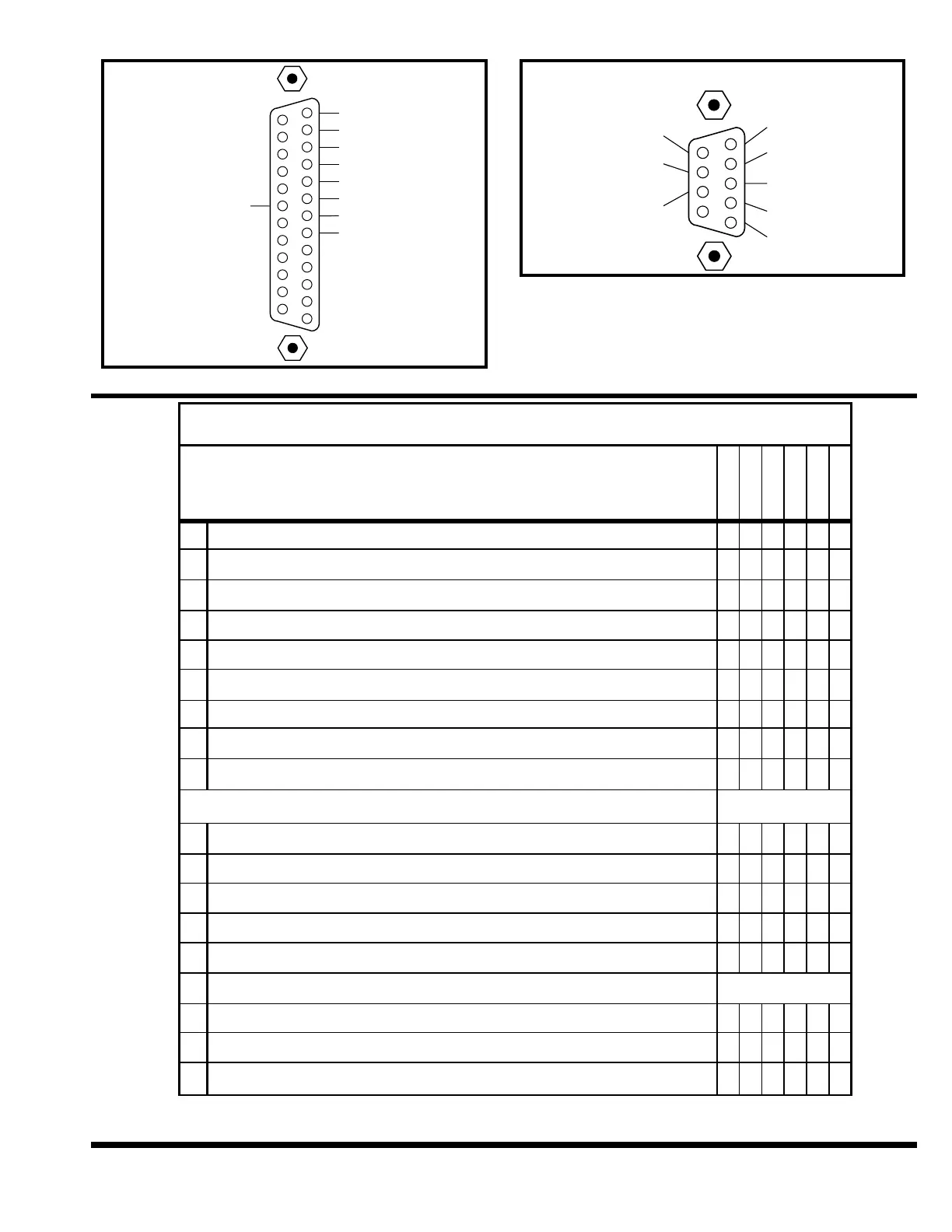

FIGURE 9-22 – PC 9-Pin Serial Port

SG

DTR Output

TD Output

RD Input

DCD Input

DSR Input

RTS Output

CTS Input

5

4

3

2

1

6

7

8

DB9M

SG

DCD Input

DTR Output

13

7

8

20

25

1

DB25M

14

2

3

4

5

6

FG

TD Output

RD Input

RTS Output

CTS Input

DSR Input

MAINTENANCE CHECKLIST – FM HYDRAULIC PRESS BRAKE

Check entire machine for loose fasteners – tighten if necessary.

Wipe entire machine clean.

Check machine levelness.

Check ram guide clearances – relevel if necessary.

Check ball seat clearances - adjust if necessary.

Replace pressure line filter element(s).

Adjust swivel end-guide bearings.

Replace filter(s) in air-cooled heat exchanger(s) (optional).

Replace reservoir air filter – breather(s).

1

2

3

4

5

6

7

8

9

DAILY

WEEKLY

MONTHLY

3 MONTHS

6 MONTHS

YEARLY

LUBRICATION SCHEDULE

ABOVE INTERVALS ARE BASED ON ONE SHIFT AND NORMAL PRESS BRAKE OPERATION.

DETAILED INSTRUCTIONS FOR SERVICING THE MACHINE CAN BE FOUND IN THIS MANUAL.

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

1

2

3

4

5

6

7

8

9

Check reservoir oil level(s).

Check lubrication at both guides.

Lubricate cylinder clevis pin(s).

Clean and flush ram guides with oil.

Check for water in reservoir(s).

Clean and lubricate Heavy Duty or Plate Gage horizontal guide rails.

Lubricate Auto Crown

pins (optional).

Clean and lubricate Heavy Duty or Plate Gage ballscrews (optional).

Drain, clean and refill hydraulic reservoir(s).

CHECK OR ADJUSTMENT

X

WHEN INDICATED

X

Loading...

Loading...