ADDITIONAL OPERATOR

CONTROLS

One additional Palmbutton Operator Station

and/or footswitch can be installed on the FM. See

previous description of FM CONTROL STATION in

SECTION 6 for the operation of these controls.

GAGE INSTALLATION

The CINCINNATI INCORPORATED FM gages are

shipped disassembled from the machine. Remove

the gage assemblies from their packing

container(s). Remove any protective wrapping and

clean the parts.

IMPORTANT: Do not install the gage or make

electrical connections until a CINCINNATI

INCORPORATED Service Representative is

present.

For the final adjustments and installation of the

gage, see the MAINTENANCE & ADJUSTMENTS,

SECTION 9, of this manual.

BACKGAGES

Set-up and operating techniques for the optional

backgage are described in SECTION 5. Also

described are the gage assemblies and fingers used

with these backgages. Programming is described in

SECTION 7.

There are two optional backgages available on the

FM. They are the CNC Plate Gage and the CNC

Heavy Duty Backgage.

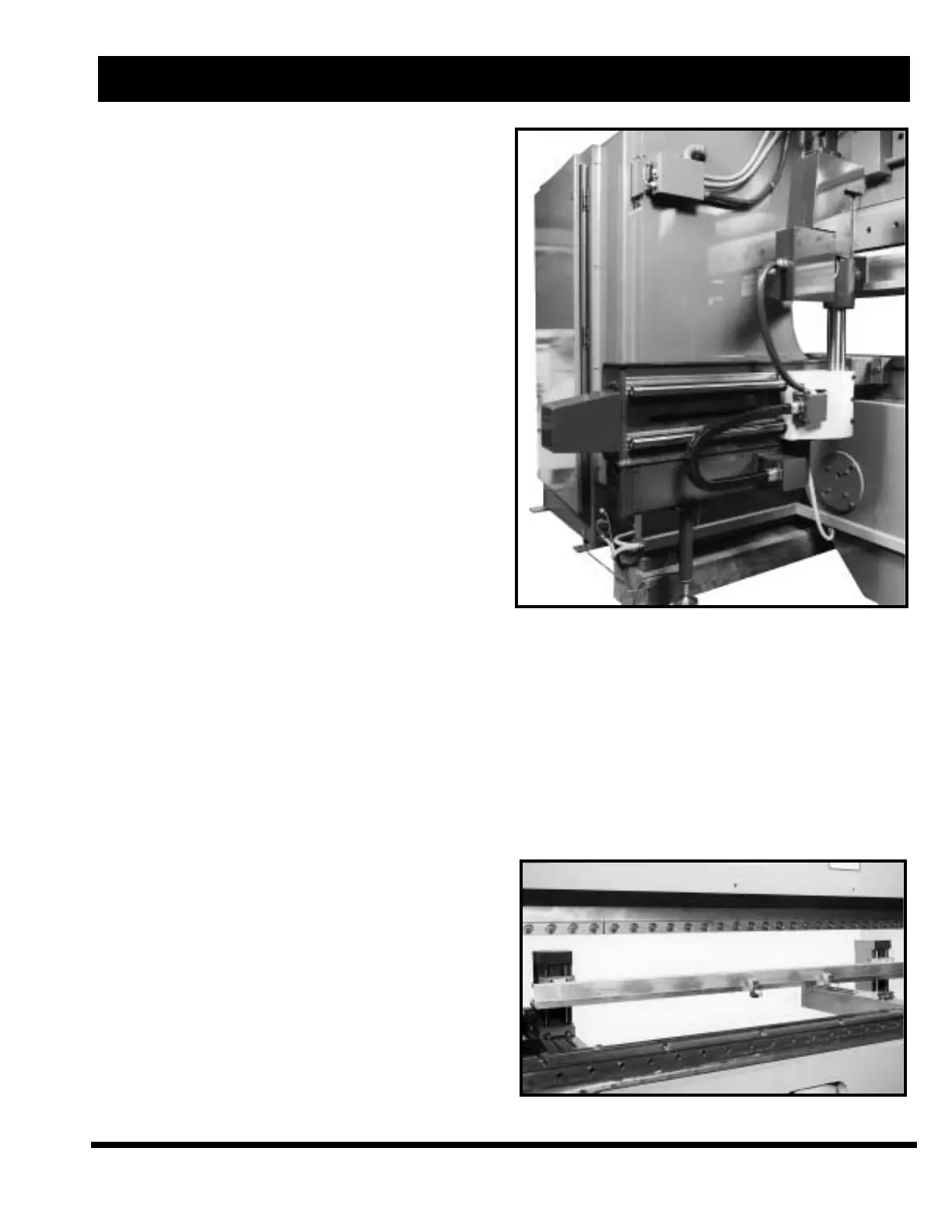

CNC PLATE GAGE

This backgage is intended for applications where

the majority of material is heavy sheets or plate

weighing over 100 lbs. (45.4kg). It is a dual drive

type with a 24” (610mm) or 40” (1016mm) range

powered X-axis. The R-axis is 8” (203mm) program-

mable powered vertical adjustment. See Figure 8-1.

The Plate Gage is programmable and can be posi-

tioned and sequenced in the horizontal X-axis and

vertical R-axis.

FIGURE 8-1 – CNC Plate Gage

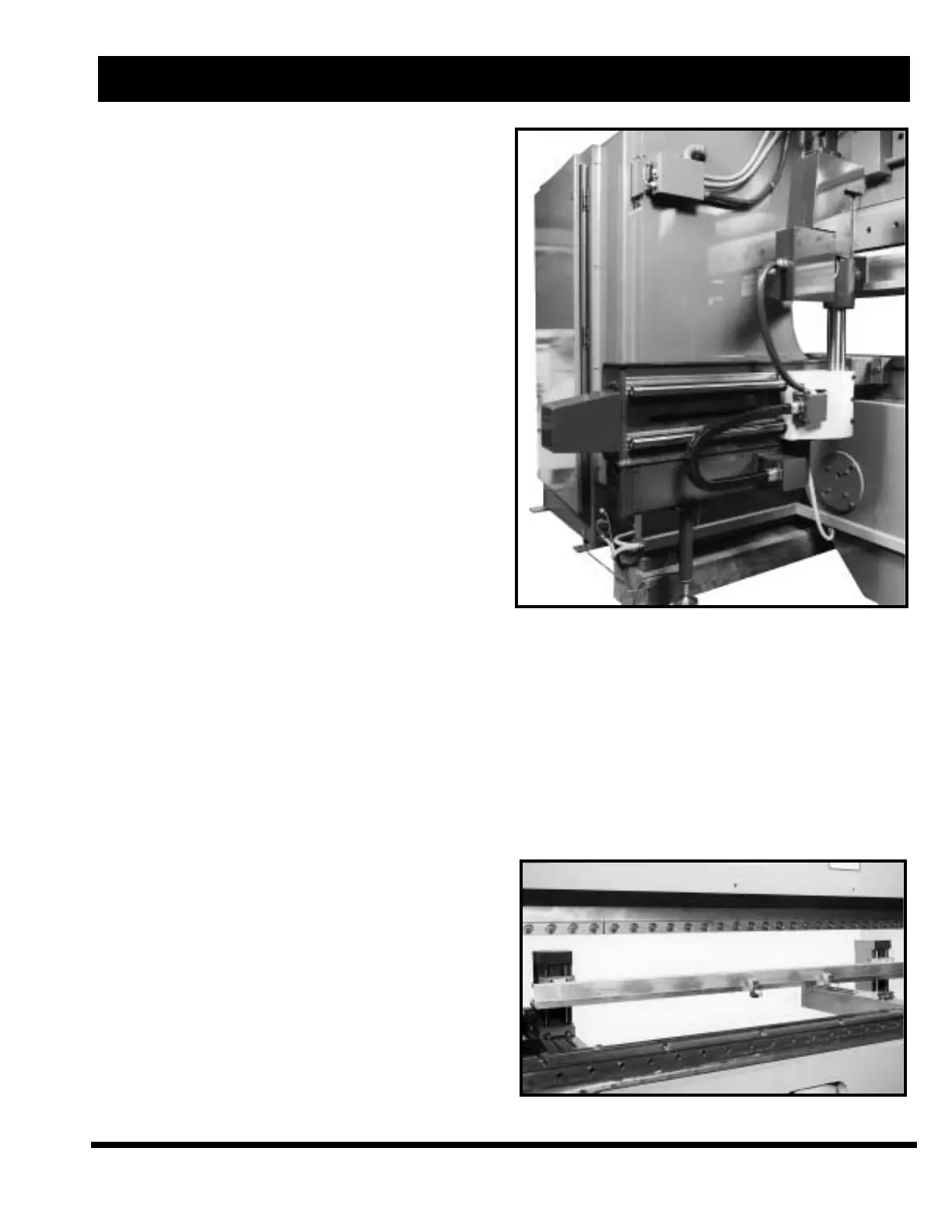

CNC HEAVY DUTY BACKGAGE

This backgage has a 24” (610mm) or 40” (1016mm)

powered X-axis (front-to-back) whose position can

be programmed by entering numerical data into the

CNC Multi-Axis Control. The positioning speed is

1200 in/min. (508 mm/sec). This backgage has

vertical adjustment up to 8” (203mm) either manu-

ally using a handwheel on each guide assembly or

by a programmable powered adjustment with a

positioning speed of 300 IPM. See Figure 8-2.

FIGURE 8-2 – CNC Heavy Duty Backgage

EM-446 (N-08/99)

8-1

SECTION 8 OPTIONS

Loading...

Loading...