CAPACITY

The CNC Plate Gage has a 24” or 40” X-axis and an

8” or 12” R-axis. The X-axis is driven at 400

in./min., and the R-axis at 90 in./min. If large

plates or sheets weighing over 150 lbs. (68 Kg) are

to be gaged, then the CNC Plate Gage should be

used.

The CNC Heavy Duty Backgage has a 24” or 40” X-

axis and a manual or programmble 8” or 12” R-

axis. The X-axis is driven at 1200 in./min., and the

optional programmable R-axis at 300 in./min. The

CNC Heavy Duty Backgage should only be used for

sheets 1/4” (6.4mm) maximum thickness and

weigh less than 150 lbs. (68 Kg).

IMPORTANT: Reasonable care should be used

when positioning heavy material against

the gages. Heavy shock loads could dam-

age parts of the gage.

GAGE ASSEMBLY

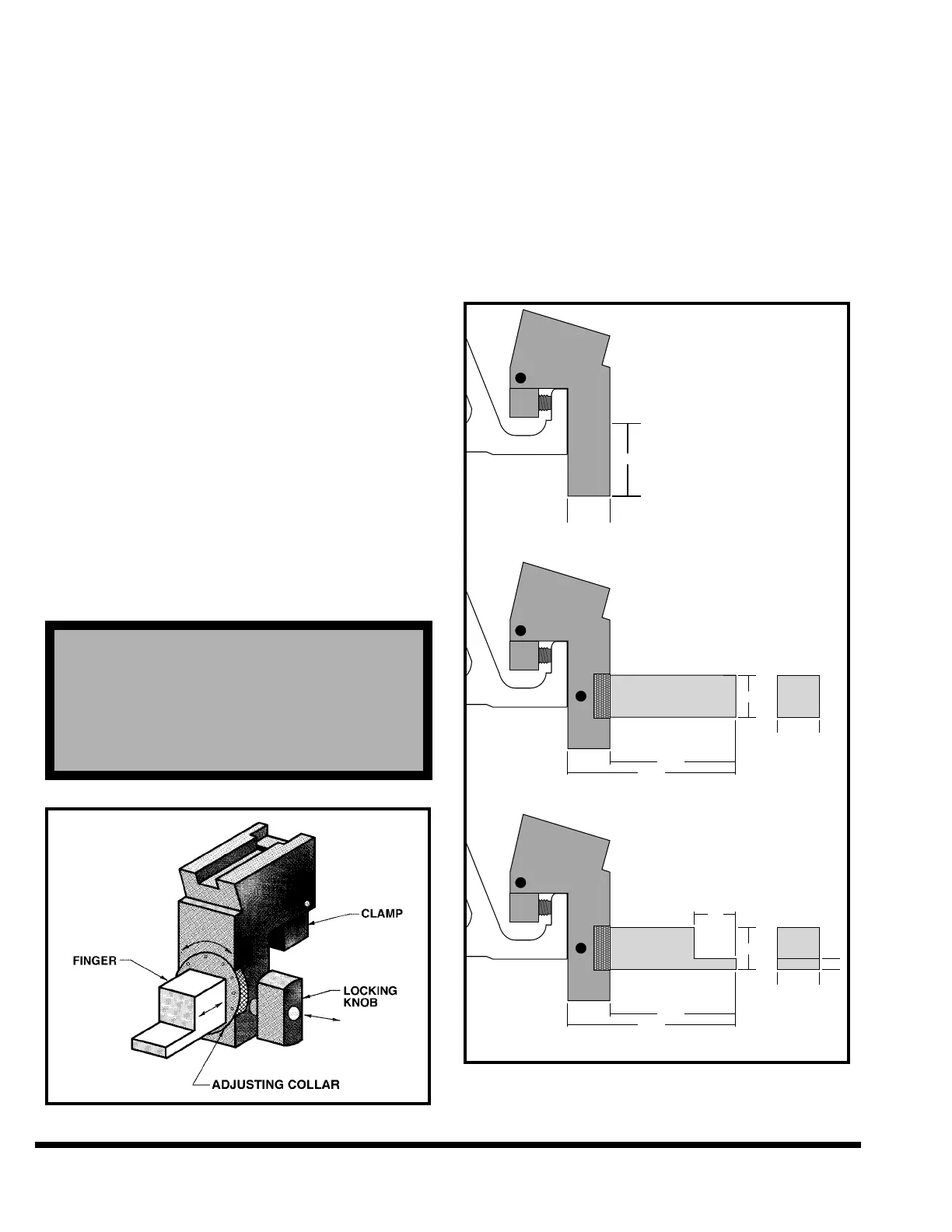

Two gage assemblies are furnished with each back-

gage and are mounted on the backgage gage bar.

The gage assemblies (Figure 5-7) are manually

positioned along the length of the gage bar, usually

centered on the tooling and spaced apart a distance

less than the length of the workpiece.

FIGURE 5-7 – Gage assembly

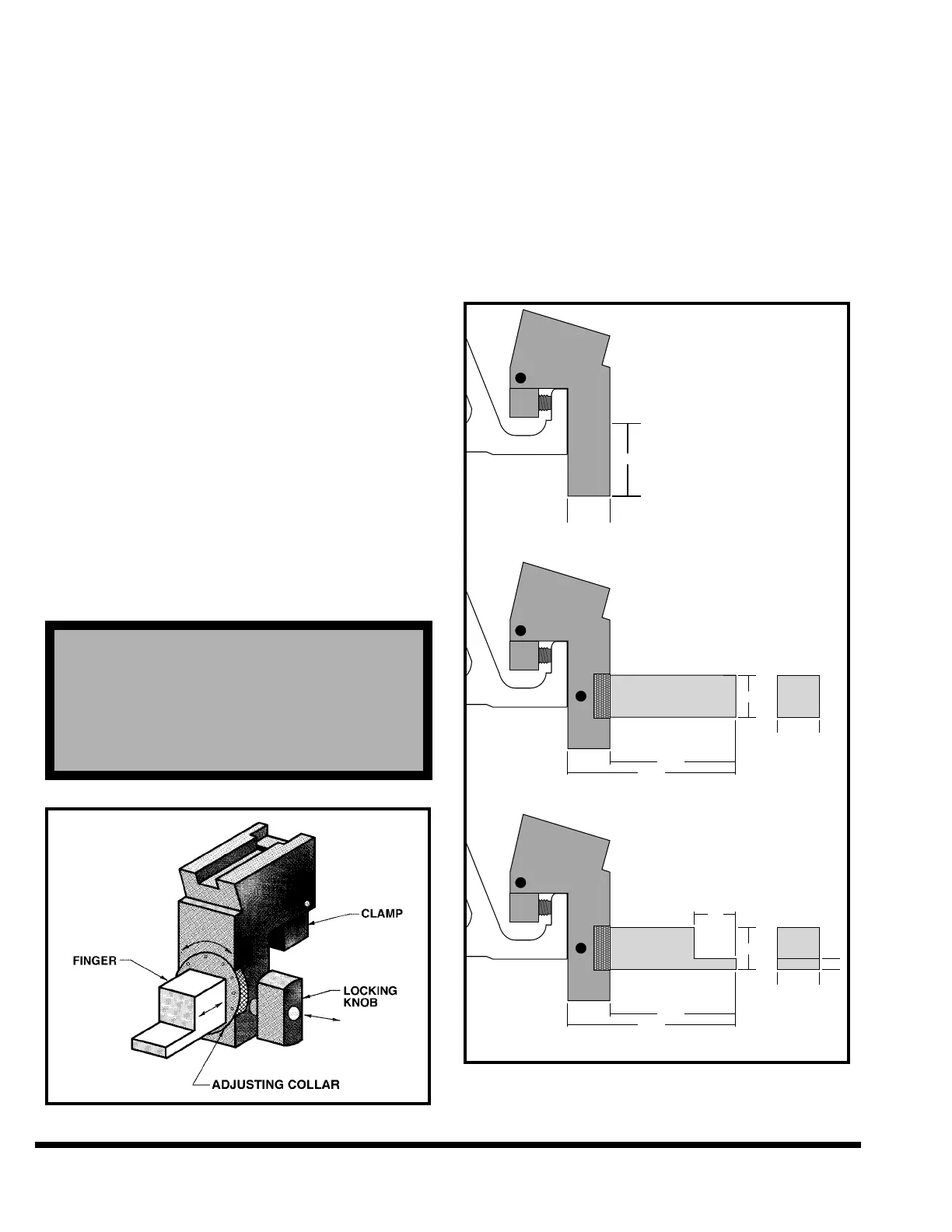

Two pairs of gage fingers are furnished with each

backgage. The 1” (25mm) gage finger or the 1/4”

(6.4mm) gage finger is installed into the gage

assembly as shown in Figure 5-8. The 1” (25mm)

gage finger should be used wherever possible, as it

provides the largest target and contact area. The

1/4” (6.4mm) gage finger can be rotated in the gage

assembly to provide either a 1” (25mm) or a 1/4”

(6.4mm) high surface for short flanges. An optional

1/8” (3.2mm) gage finger can be furnished for

smaller flanges. 1”, 1/4”, and 1/8” optional flip fin-

gers are also available.

FIGURE 5-8 – Standard gaging surfaces

STD. GAGE ASSEMBLY – 1" FINGER

STD. GAGE ASSEMBLY – 1/4" FINGER

Loading...

Loading...