Machine must be connected to a good earth

ground. A ground lug on the line side of the

machine main disconnect is provided for this pur-

pose. Refer to local and state codes for acceptable

grounding methods.

Note: If CINCINNATI INCORPORATED Service Rep-

resentative is not present, call before pro-

ceeding any further or starting machine.

He will complete all electrical connections and

check motor rotation.

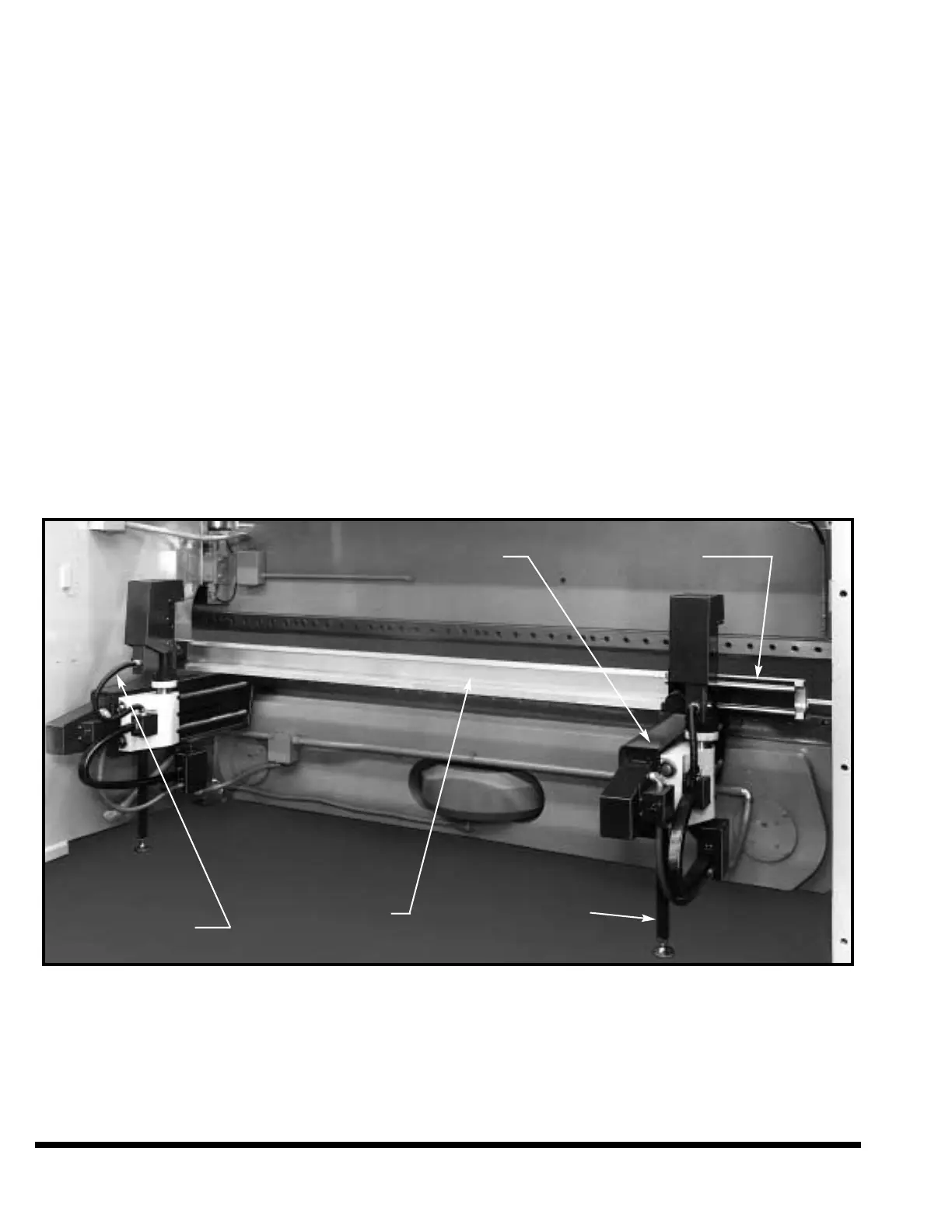

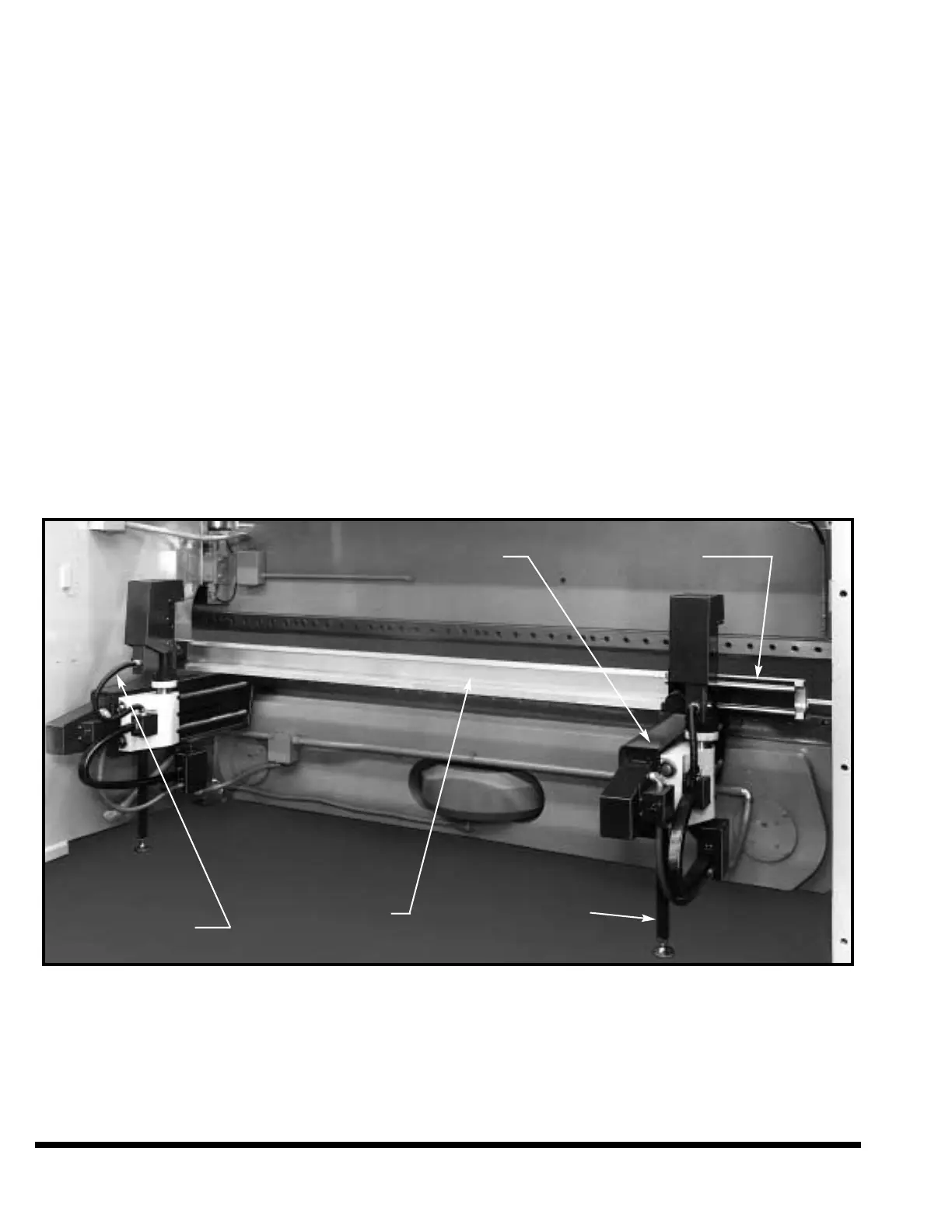

CNC PLATE GAGE (Optional)

The CNC Plate Gage is an optional feature which

provides capability for plate forming applications.

Remove the backgage arm assemblies and gage bar

from packing boxes. Remove any protective wrap-

ping and clean the parts. Backgage arm assemblies

are identified as “LEFT HAND” or “RIGHT HAND” by

metal tags on top of the assembly. Install assem-

blies to rear dovetail slot in bed using dovetail bolts,

hex nuts and lockwashers. The “LEFT HAND”

assembly is mounted toward the left side as viewed

from the front of the machine (see Figure 2-8). Use

roll pin holes drilled at the factory to locate assem-

blies along slot. Install roll pins and tighten mount-

ing nuts securely.

Before installing gage bar, install backgage support

legs under backgage arm assemblies. Arm assem-

blies should now be leveled using leveling screws on

support legs. Place precision level on upper guide

rail and adjust screw to raise or lower rear of back-

gage arm assembly as required. Tighten leveling

screw locknuts when finished.

Install gage bar by inserting horizontal guides into

right mounting block. Mount left end of bar to

mounting plate using cap screws provided.

Do not make any electrical connections. This

will be done by a CINCINNATI INCORPORATED

Service Representative.

Clean the horizontal guide rails and lubricate by

spraying them with SAE #10 oil.

2-8

FIGURE 2-8 – CNC Plate Gage (shown with optional Auto Crown)

RIGHT ARM

ASSEMBLY

GAGE BAR SUPPORT LEG

HORIZONTAL

GUIDES

LEFT ARM

ASSEMBLY

❦

Loading...

Loading...