slots in these three members. The top of the cylin-

der contacts the top of the slot in the bed. The bot-

tom of the piston contacts the bottom of slots in the

auxiliary cross members.

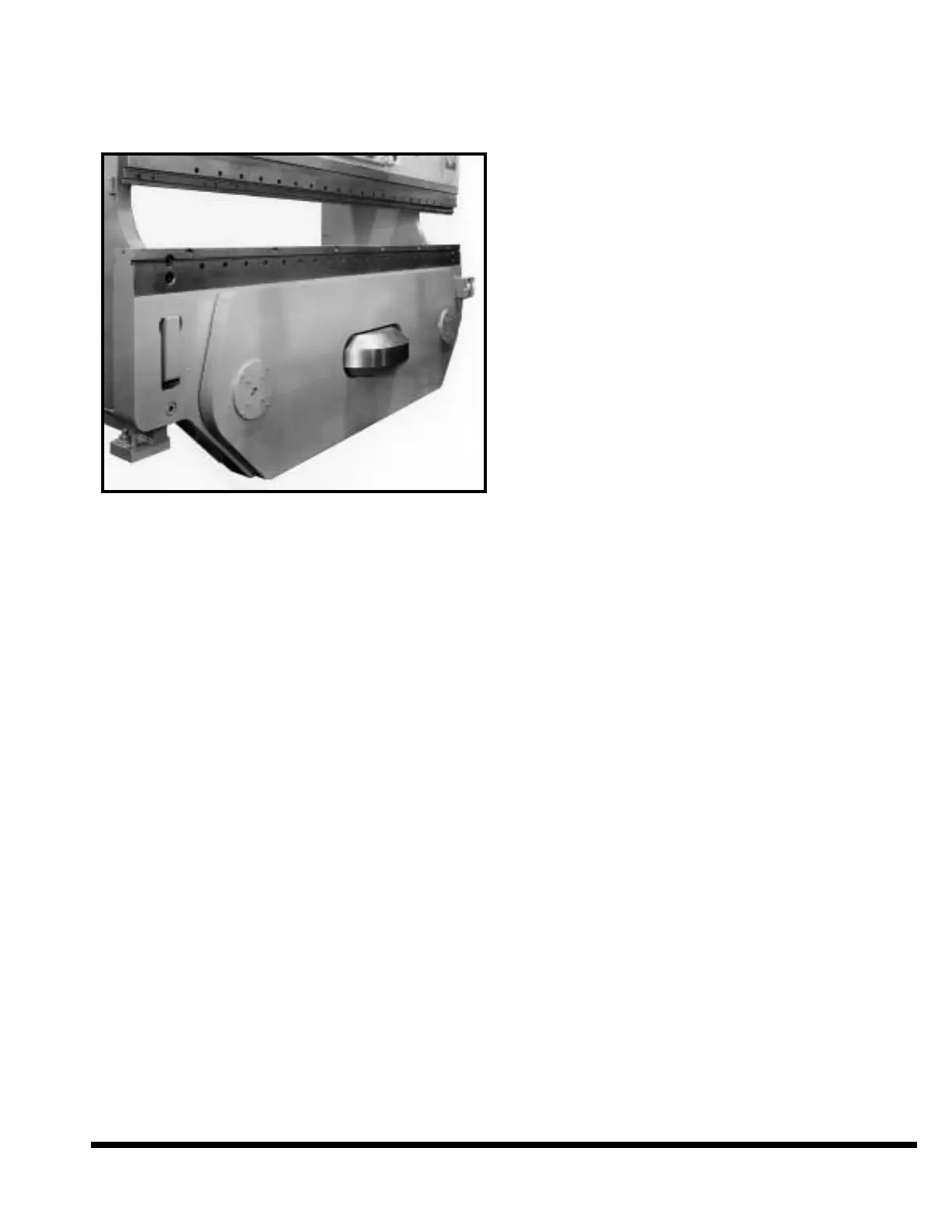

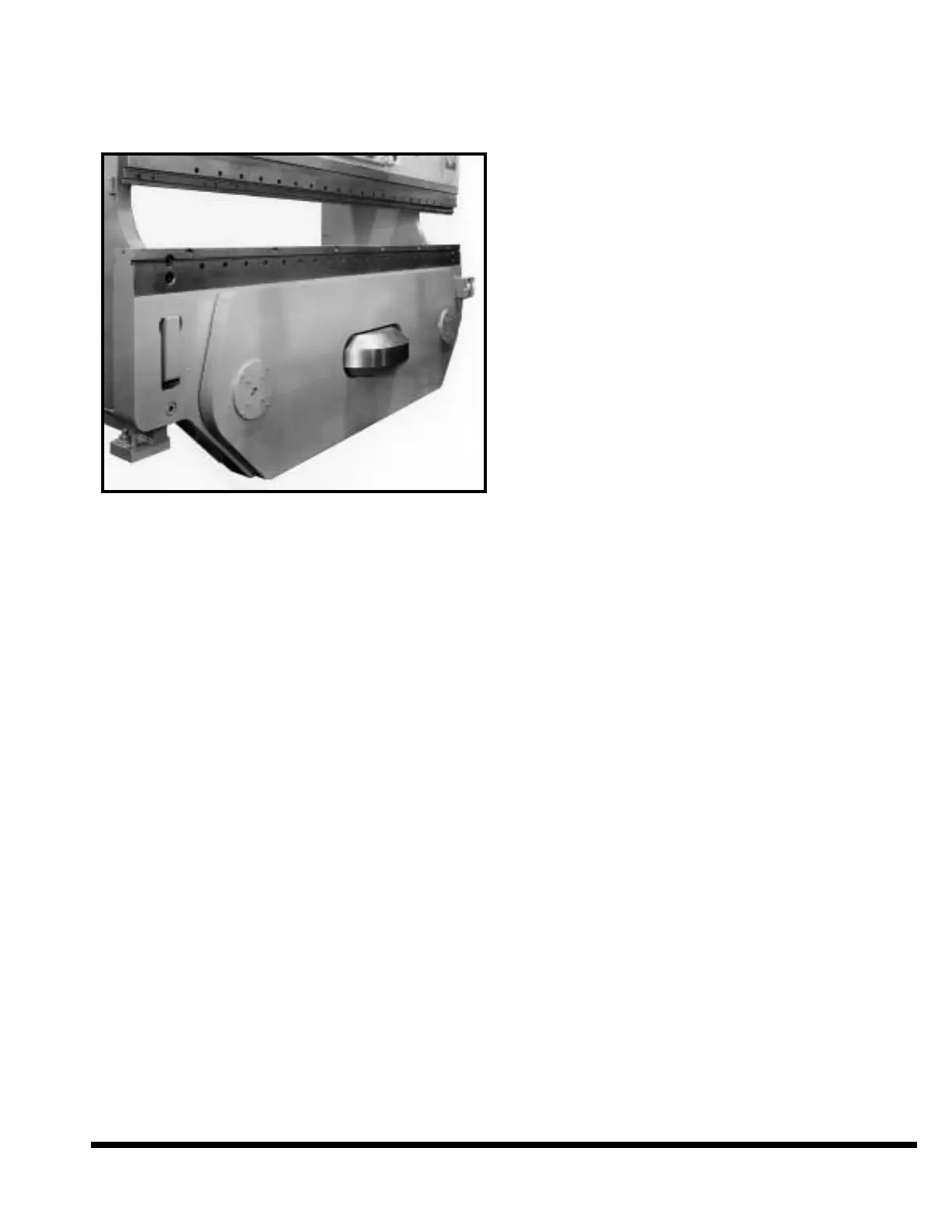

FIGURE 8-5 – Auto Crown

The force developed by Auto Crown is approximate-

ly twice as large as the forming load. This force

pushes up on the bed causing the bed to deflect up

an amount equal to the deflection of the ram. The

result is that the bed and ram remain parallel and

the upper die penetration is uniform along the bend

length. Auto Crown is available on 400FM x 10’ and

longer, 500FM and 600FM x 12’ and longer, and

750FM and 1000FM x 14’ and longer. 10’ and 12’

machines have one Auto Crown cylinder. Longer

machines have two Auto Crown cylinders.

TANDEM MODE

Tandem operation is the simultaneous operation

of two press brakes placed side-by-side. When

operating in this fashion, parts can be formed that

are as long as the total length of the two

machines. The two machines may be operated

either independently or in tandem mode. When

the machines are operated independently, they

operate as two standard FM Press Brakes. The

only limitation in independent operation is the

physical proximity of the two machines. When the

machines are operated in tandem, the right hand

machine becomes the master and all program-

ming and setup takes place on the master control.

The left hand machine becomes the slave

machine. The slave machine will duplicate all

actions of the master, both ram motions and gage

motions.

When using Tandem operation, the bending load is

typically distributed evenly and centered about the

tandem centerline. Also the beds and rams of the

two machines are symmetrical about the tandem

centerline. When the bend length spans the full

length of both machines, each machine is typically

close to being center loaded. If the overall bend

length is shorter, each machine is in an off-center

loaded condition. If the bend length is too short,

where there is no loading at the outer cylinders, the

rams will go out-of-level. These bends should only

be done on one machine operated independently.

The following information describes the controls

and procedures required to operate tandem FM

Press Brakes. It only covers items that are unique

to tandem operation. For a description of standard

operation of the FM Control, refer to SECTIONS 6

and 7.

TANDEM MACHINE CONTROLS

A single selector switch is provided on the master

machine’s electrical enclosure. This switch selects

whether the machines will operate independently

or in tandem. In the “SINGLE” position, the two

machines will operate independently; in the

“DUAL” position, the slave machine will duplicate

the actions of the master machine. Whenever the

switch position is changed, both machines will

display the MAIN MENU on the control screen.

When in Tandem Mode, the only controls that are

active on the slave machine are the RAM UP but-

ton, EMERGENCY STOP button, OPERATOR con-

trol switch and the MAIN DRIVE START and STOP

buttons. All palmbutton and footswitch stations

on the slave control will be inactive, all front panel

selection (forming speeds, stroke stops, etc.) will

be inactive.

TANDEM PROGRAMMING

Two additional program values appear on the

PROGRAM DATA screen when operating in Tan-

dem Mode. These are “SLV OFFSET” (slave offset)

and “SLV TILT” (slave tilt).

SLAVE OFFSET

In Tandem Mode, the programmed ram values are

controlled by the inboard linear transducer of the

master machine (left transducer of the right hand

machine). The “SLV OFFSET” value is applied at

the inboard transducer of the slave machine and is

used to match the inboard end of the upper die on

the slave machine to the inboard end of the upper

die on the master machine.

The slave offset is programmed between -1.000 and

+1.000 inches (-25.40 to +25.40mm). When the off-

8-3

Loading...

Loading...