set is positive, the slave machine will track a posi-

tion higher than the master. Negative values will

cause the slave to track lower than the master.

SLAVE TILT

The program value “SLV TILT” is used to set the tilt

on the slave machine. It has the same valid range

as “RAM TILT”, which is used to set the tilt on the

master machine.

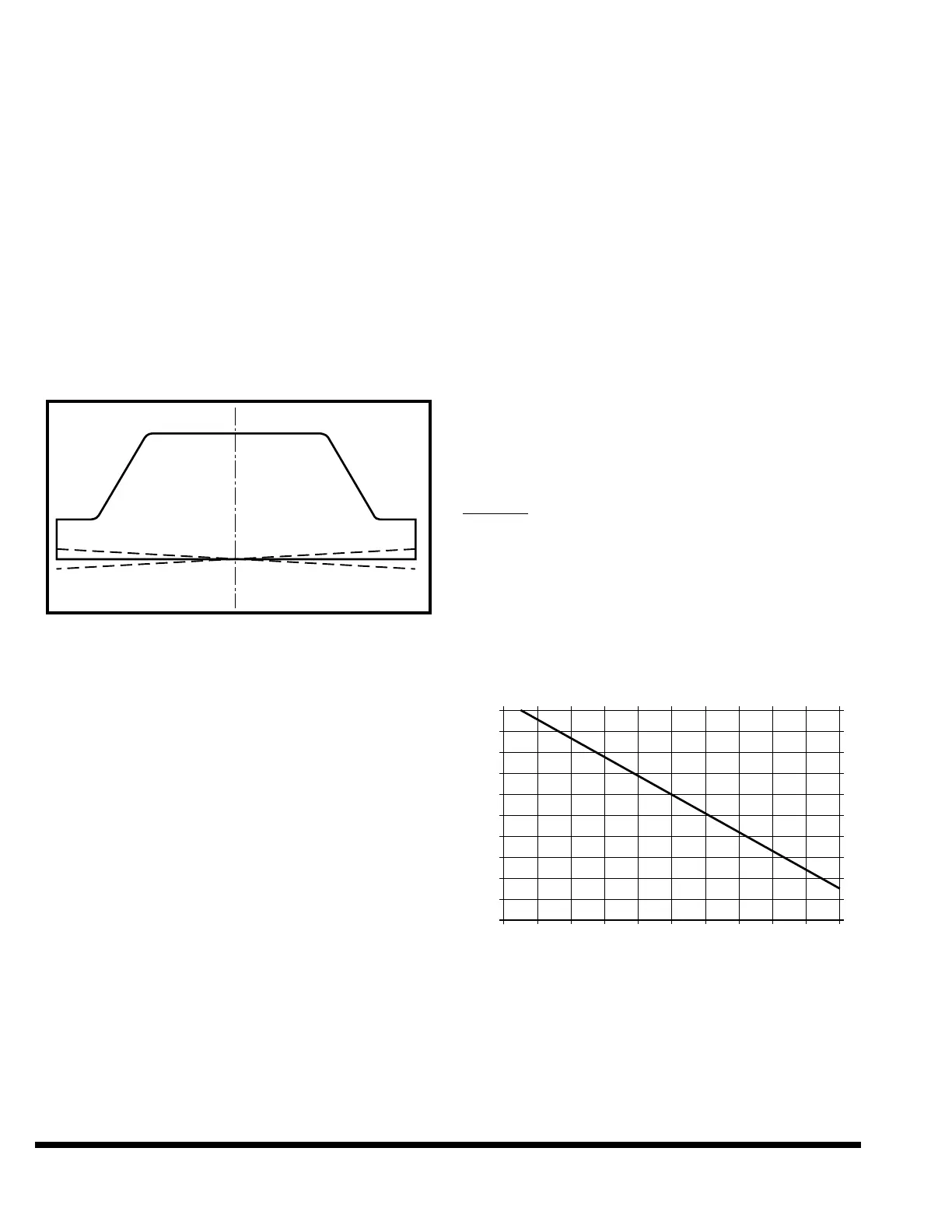

In Tandem Mode, tilt has a different effect than in

independent mode. Tilt does not affect the reversal

position of the ram at the center of the machine for

an independent machine. The two ends of the

machine are raised and lowered by half of the pro-

grammed tilt so the position of the ram at the cen-

ter remains unaffected. See Figure 8-6.

FIGURE 8-6 – Ram tilt in Single or Independent mode

For tandem machines, tilt does not affect the rever-

sal position of the ram at the inboard transducer.

The entire “RAM TILT” value is applied at the out-

board transducer of the master machine (right

transducer of the right hand machine). Positive

“RAM TILT” lowers the right end of the master

machine and negative “RAM TILT” raises the right

end of the master machine. On the slave machine,

the entire “SLV TILT” value is applied at the out-

board transducer (left transducer of the left hand

machine). Positive “SLV TILT” raises the left end of

the slave machine and negative “SLV TILT” lowers

the left end of the slave machine. See Figure 8-7.

Note: When tilts and offsets are used, the total avail-

able stroke length of the machine is reduced.

The ram will stop on the up stroke when the

highest cylinder reaches its maximum up

position. Likewise, the ram will stop on the

down stroke when the lowest cylinder reach-

es its maximum down position.

REVERSAL TONNAGE

When programming the reversal tonnage in Tan-

dem Mode, the maximum value becomes the com-

bined tonnage of both machines. For example,

when two 2000 FM Press Brakes are working in

tandem, the maximum tonnage that can be

entered is 4000 tons. The programmed tonnage

(and the tonnage displayed in the DIAGNOSTIC

screen) will only indicate the actual tonnage if a

bend the full length of both machines is made. For

bends shorter than full length, the actual tonnage

will be less than programmed or displayed.

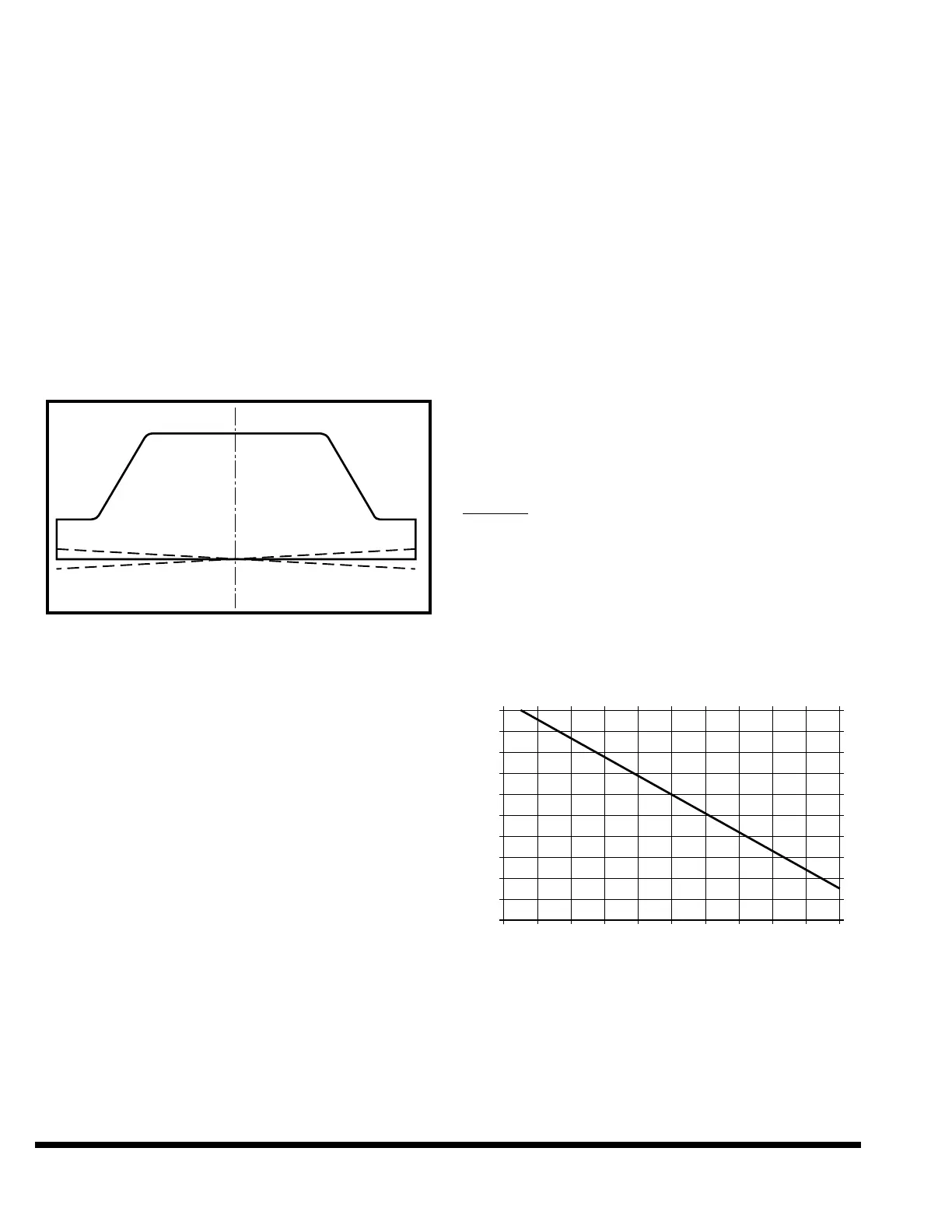

To determine the program tonnage to be applied to

a part, use the bend length to select a Force Mul-

tiplier from the Tonnage Adjustment chart sup-

plied with your specific tandem machines. (This

chart will vary depending on the machine’s ton-

nage, nominal length and extension length(s). The

following chart is for 2000 FM tandem machines

with 20 ft. nominal length each and a 12 inch

extension on the inboard end of both machines.)

Multiply the required tonnage by the Force Multi-

plier and enter this value into the control. If this

value is more than the maximum value for the

tandem machines, enter the maximum value.

Example

: A 400 inch bend length part requires

1000 tons to form the part or to protect

the tooling. On the 2000 FM tandem

previously mentioned, the Force Multi-

plier from the Tonnage Adjustment

chart is 1.51. Multiply 1000 ton x 1.51

= 1510. Input 1510 for tonnage in the

program. This calculation assumes

that the part is centered about the tan-

dem centerline.

Tonnage Adjustment

LIGHT GUARDS

If a light guard is to be used to safeguard the

machine during tandem operation, the light guard

must be connected to the master machine and must

cover the entire workspace of the two machines. A

light guard connected to the slave machine will not

be active during tandem operation.

Loading...

Loading...