It is very important to keep the oil clean. All pre-

cautions must be taken to keep the oil clean, free

of chips, grit, water, sludge, etc. The oil should be

drained and replaced after one year of service.

Replace the oil sooner if sludge or other contami-

nation is present. The drain valve is located in the

bottom of the reservoir(s). This valve should be

cracked once a month to remove any accumulat-

ed moisture. Check the oil level(s) daily.

New oil stored in drums is usually not as clean

as the filtered oil shipped with the machine. Oil

should be pumped through a 3 micron filter.

After the oil is changed, the Multi-Axis Control

display should be checked periodically to see if a

dirty filter error message appears. Change the fil-

ter element(s) if required.

OIL FILTER

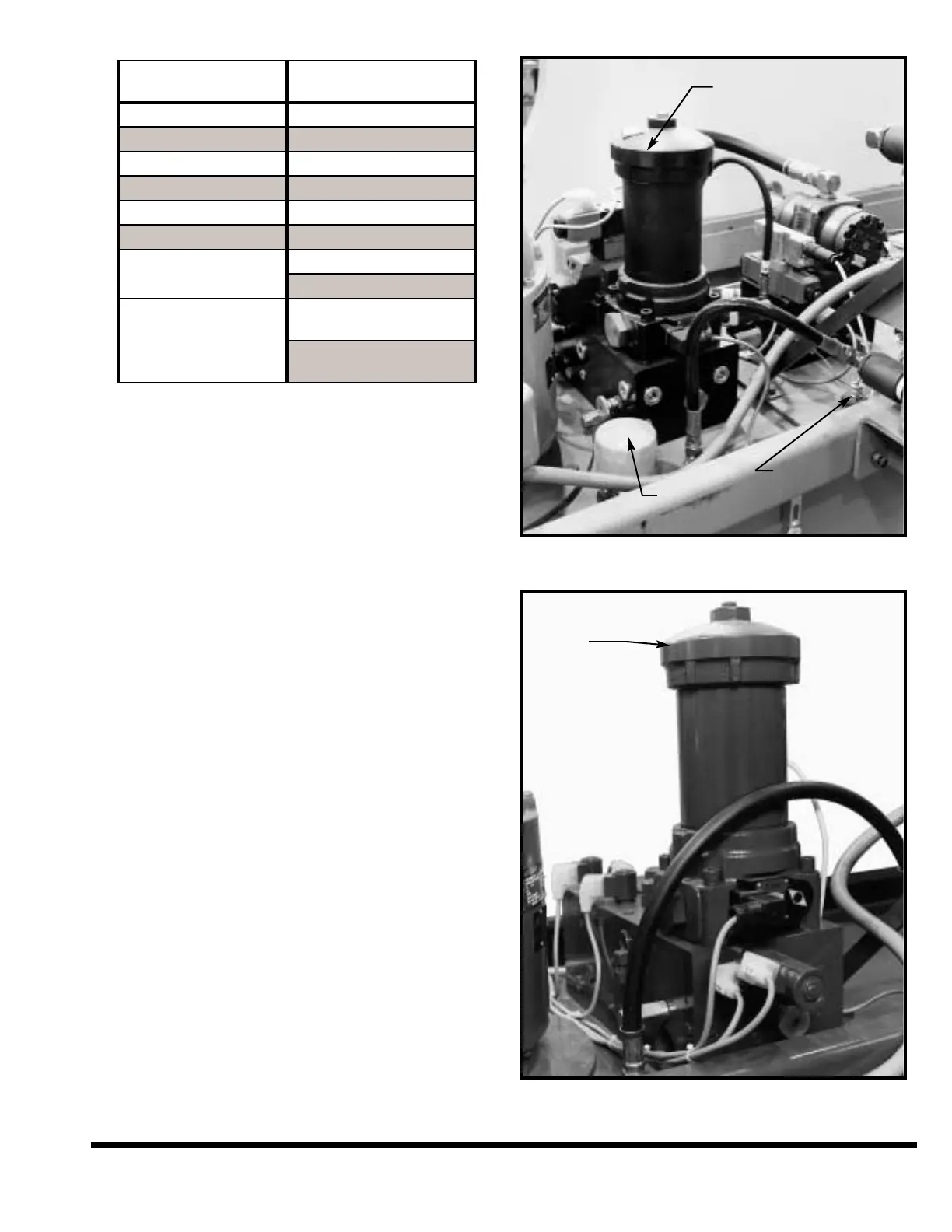

The high pressure filter is located on the

motor/pump mounting plate on top of the main

reservoir(s). See Figure 9-5A and 9-5B. When the

ram is moving, oil flows from the variable volume

pump through the high pressure filter.

When the filter has reached its dirt holding

capacity, an error message will appear on the

Multi-Axis Control display. The message will

remain until the dirty element is replaced. To

replace the filter, place the ram at the bottom of

the stroke and block the ram, turn OFF the main

drive motor(s) and the disconnect switch on the

main electrical enclosure and install a safety

lockout. Remove the top cap on the filter and the

dirty filter element. Install a new element and

replace the top cap.

FIGURE 9-5A – High pressure oil filter

(For 400 - 750 FM Standard)

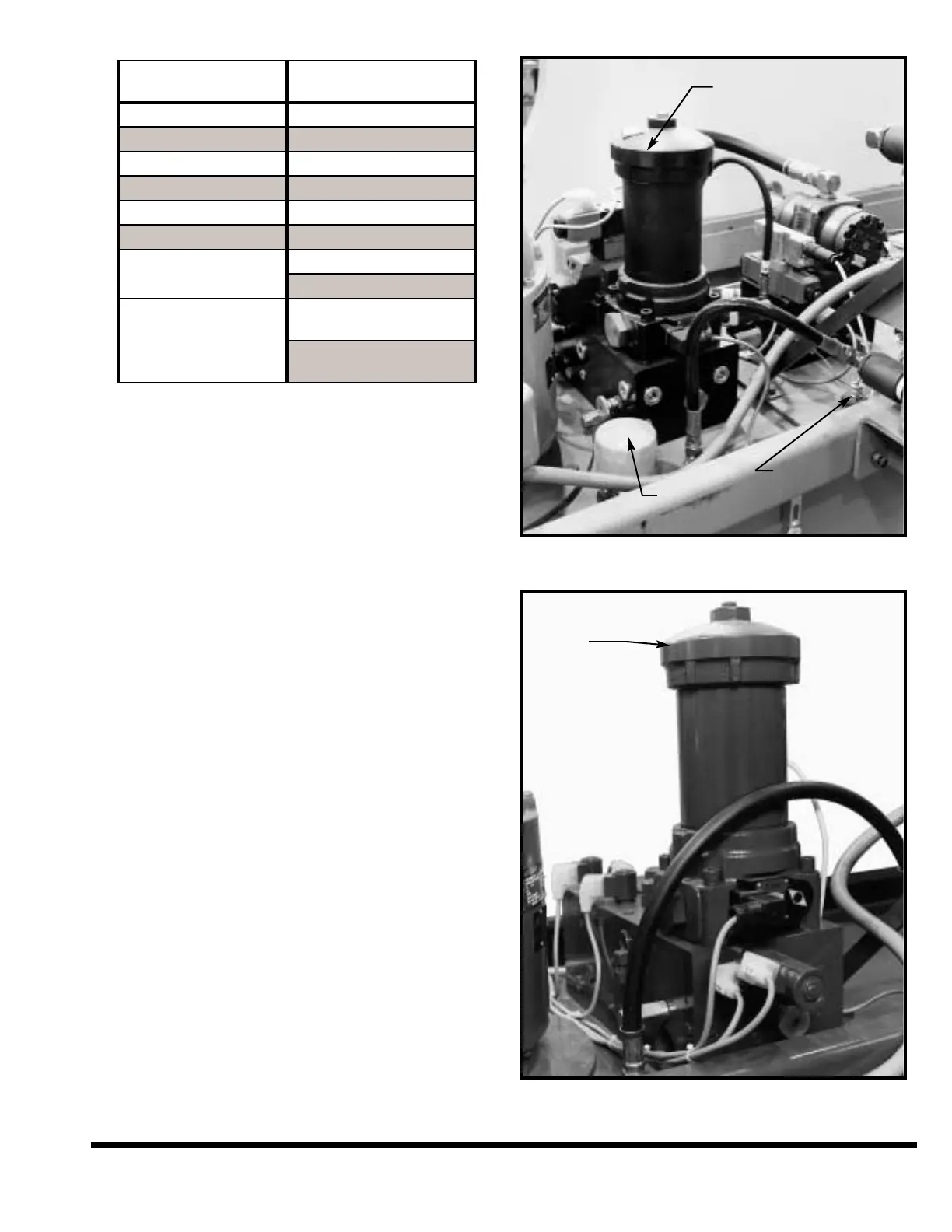

FIGURE 9-5B – High pressure oil filter

(For Hydraulic Speed Package & 1000 - 2000 FM)

155 GAL.

190 GAL.

230 GAL.

205 GAL. TOTAL

266 GAL.

Loading...

Loading...