OPERATING TECHNIQUES

The following guidelines will help the operator avoid

operating problems, producing bad parts, causing

injury to himself or damage to the tooling or machine.

TOOLING AND SETUP

◆ DO inspect the tooling carefully before starting

any job. It may be impossible to compensate for

badly worn dies and they could create a safety

hazard.

◆

DO select tooling which is correct for the job and

compatible with machine capacity. It is especial-

ly important to have the exact tooling when

recalling a previously run program from storage.

◆ DO ensure that tooling shoulders are tightly

seated against ram and filler block, and that

upper and lower dies are aligned front-to-back.

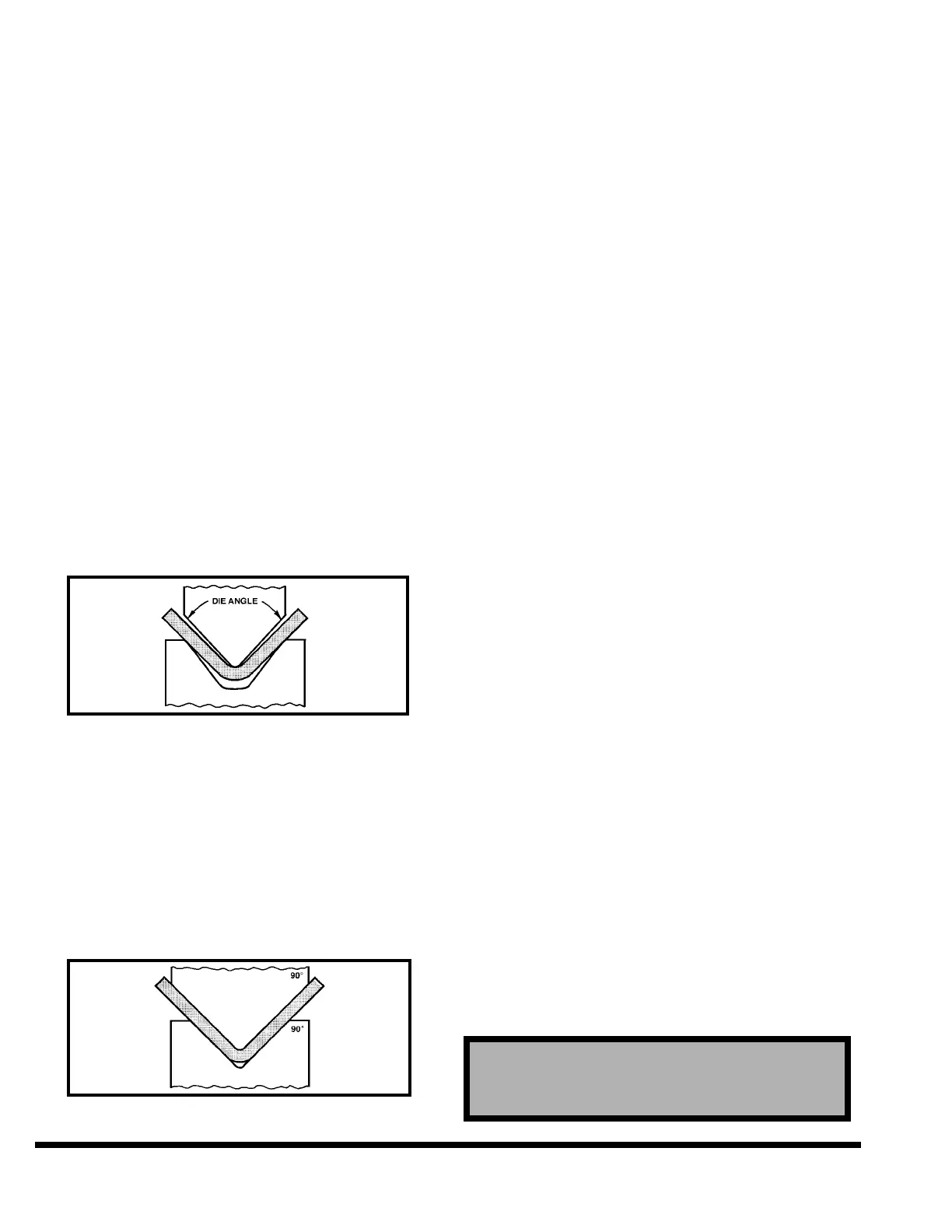

◆ DO NOT attempt to bend a part to the same

angle as the die when using ANGLE. Dies must

have sufficient allowance for springback so the

part does not bottom in the dies. It may be nec-

essary to use 80° (or less) dies when 90° air

bending for certain materials with large “spring-

back”. See Figure 5-17.

FIGURE 5-17 – Air bend

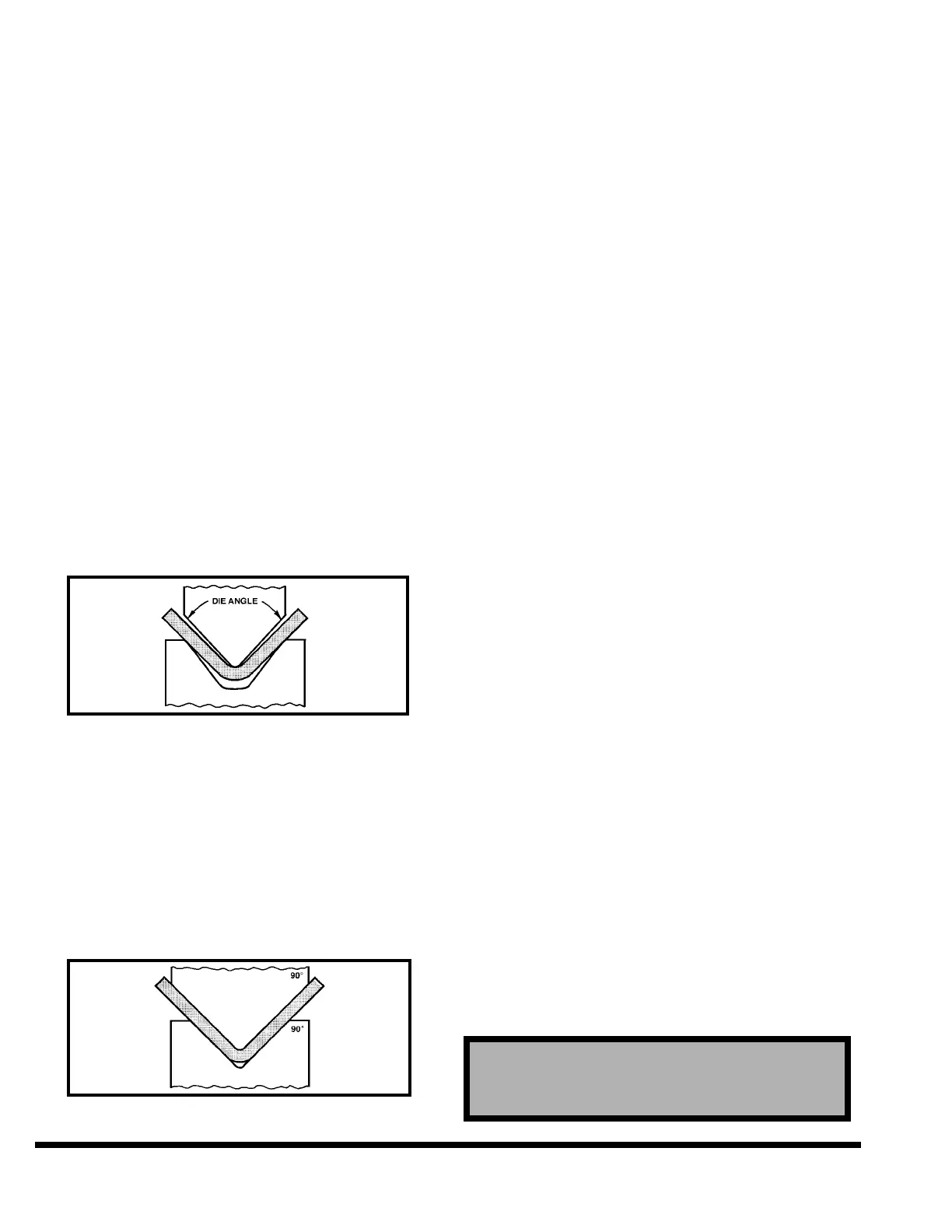

◆ DO NOT attempt to air bend a part when TON-

NAGE reversal has been selected. Bottoming dies

must be used when reversing on tonnage. See

Figure 5-18.

Note: Either air bend or bottoming dies can be

used when POSITION reversal has been

selected. However, sufficient clearance in

the dies and careful selection of the rever-

sal position and maximum tonnage is nec-

essary to avoid excessive tonnage build-up.

FIGURE 5-18 – Bottoming

◆ DO NOT use ANGLE or TONNAGE reversal

when punching. POSITION reversal should be

selected for punching.

◆ DO use as large a vee die opening as possible

when air bending. Larger vee openings are less

sensitive to material thickness variations,

deflections and tooling height variations.

◆ DO make ram tilt and die shimming adjust-

ments as soon as possible when setting up a

program as they may affect program inputs.

RUNNING

◆ DO NOT start running a job until the proper

methods and safeguards to protect the operator

and others from injury are understood and are

in place.

◆ DO NOT jog through the bend. Once ram has

reached speed change position, motion should

be continued through the bottom of the stroke.

◆ DO remove burrs or keep burrs up on material

for more consistent bends.

◆ DO run production in same speed in which the

setting up part was made.

◆ DO NOT make angle corrections in the middle

of a production run unless two or more consec-

utive bends are out-of-tolerance.

◆ ALWAYS block the ram or position the ram at

bottom of the stroke and turn “OFF” STROKE

CONTROL switch and remove the key whenever

leaving the machine.

GAGES

◆ DO ensure that gaging surfaces will not inter-

fere with the tooling or ram when setting up or

running a job.

◆ DO use the gaging surface which provides the

largest possible gaging target.

◆ DO spread gage fingers as far as possible to

achieve the best gaging accuracy.

◆ DO support workpiece in the gaging position,

both in front and rear of the bed.

REMOVING TOOLING

CAUTION

Before proceeding, read guidelines in SAFETY

section for removing tooling.

5-8

Loading...

Loading...