The CNC Plate Gage is also furnished with a pair of

heavy duty gage blocks. They are non-adjustable

hardened steel assemblies, which are generally rec-

ommended for gaging large sheets or plates over

100 lbs. (45 kg).

The face of the gage fingers is the contact surface

and gaging surface for the workpiece when it is

pushed through the dies for gaging. The distance

from the face of the gage finger to the centerline of

the dies is the gage distance.

IMPORTANT: Do not gage from the front sur-

face of the aluminum gage bar due to wear

and possible damage of this surface.

It is generally recommended that two-point gaging

be used. This minimizes sheet edge camber effect

and allows greater flexibility in positioning gage

contact points. See Figure 5-9.

FIGURE 5-9 – Two-point gaging

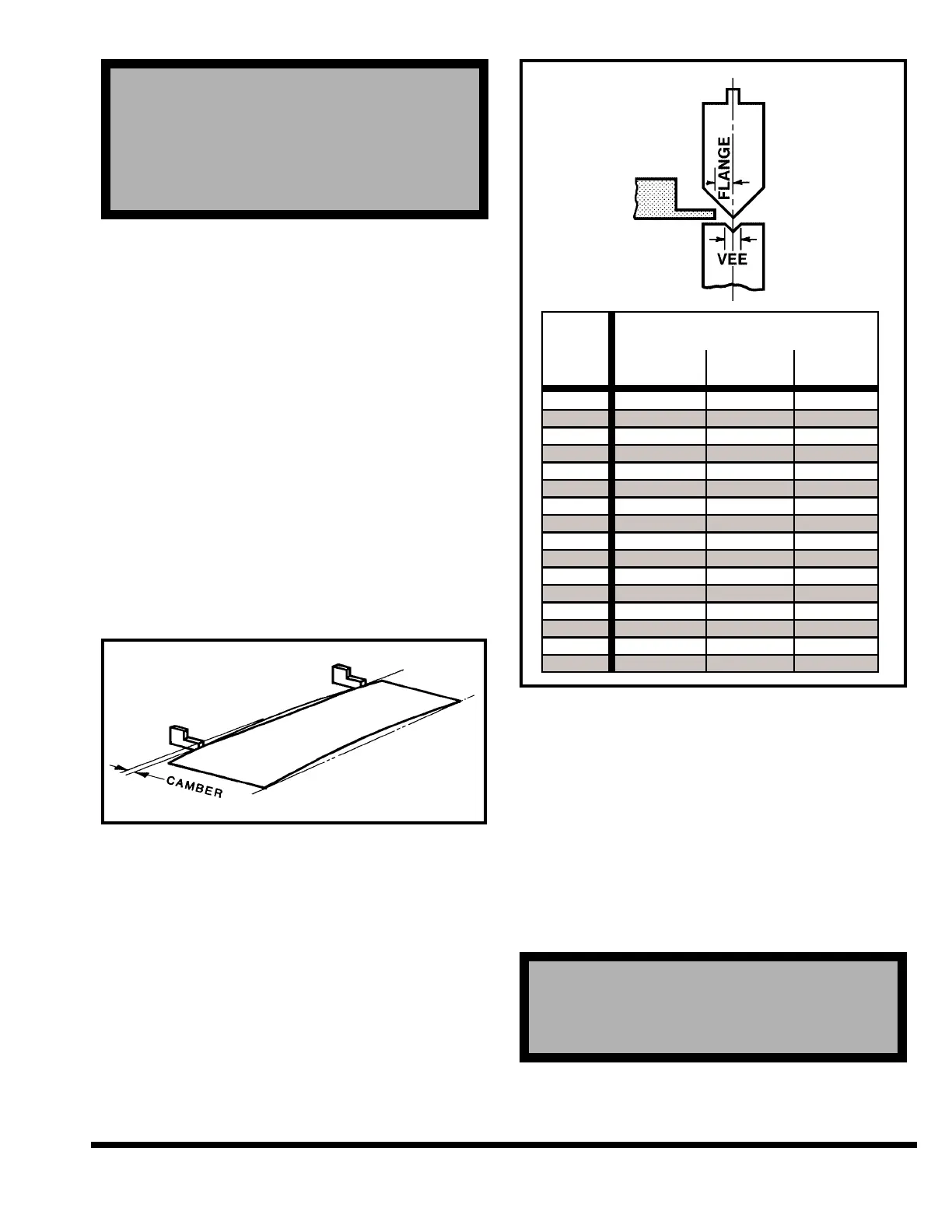

To select the gage finger for the forming job to be

run, refer to Figure 5-10. This chart provides the

minimum flange size it is possible to form with a

given size vee die.

FIGURE 5-10 – Minimum flange size

IMPORTANT: The selected gage surface should

be analyzed carefully to avoid interference

with the tooling and yet provide a large

enough target to ensure part contact.

ADJUST GAGE FINGER POSITION

Vertical position of the gage surfaces with man-

ual “R” are adjusted by turning the hand cranks

on each CNC Heavy Duty Backgage carriage

(Figure 5-11).

! ! ! DANGER ! ! !

! ! ! DANGER ! ! !

DO NOT REACH THROUGH DIE AREA TO

ADJUST “R”. GO TO REAR OF MACHINE TO

MAKE ADJUSTMENT.

! ! ! DANGER ! ! !

! ! ! DANGER ! ! !

DO NOT INSTALL OR REMOVE GAGE FINGER

OR GAGE ASSEMBLY BY REACHING THROUGH

DIE AREA. REMOVE GAGE ASSEMBLY FROM

GAGE BAR USING SPECIAL HAND TOOL FROM

FRONT OR GO TO REAR OF MACHINE TO MAN-

UALLY REMOVE GAGE ASSEMBLY.

5-5

Loading...

Loading...