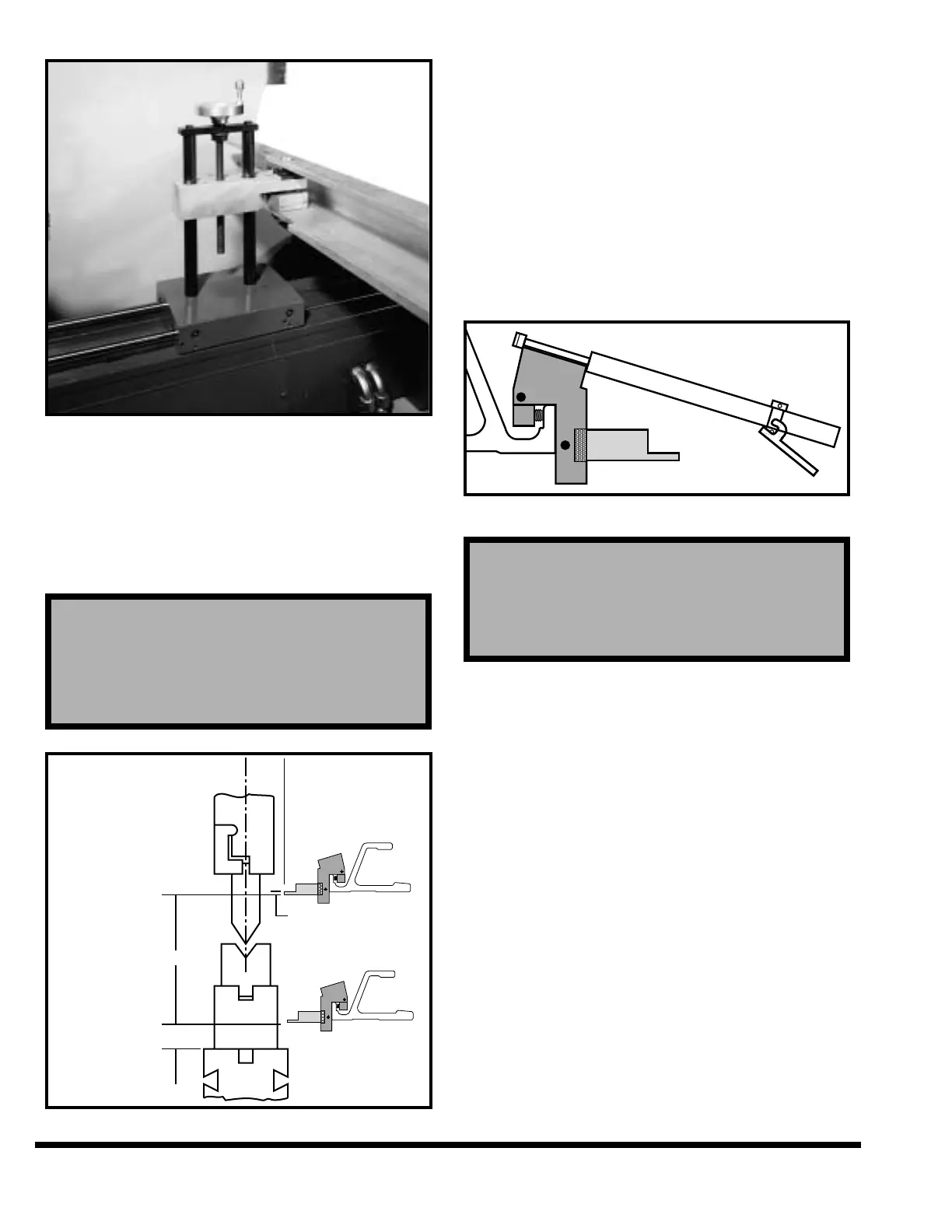

FIGURE 5-11 – Adjusting vertical gage position

Vertical position of the gage surfaces with power “R”

axis are adjusted with the program or they can be

adjusted with the gage jog softkeys. The best height

for the gages will depend upon the shape of the part

being formed. Standard adjustment limits are

shown in Figure 5-12.

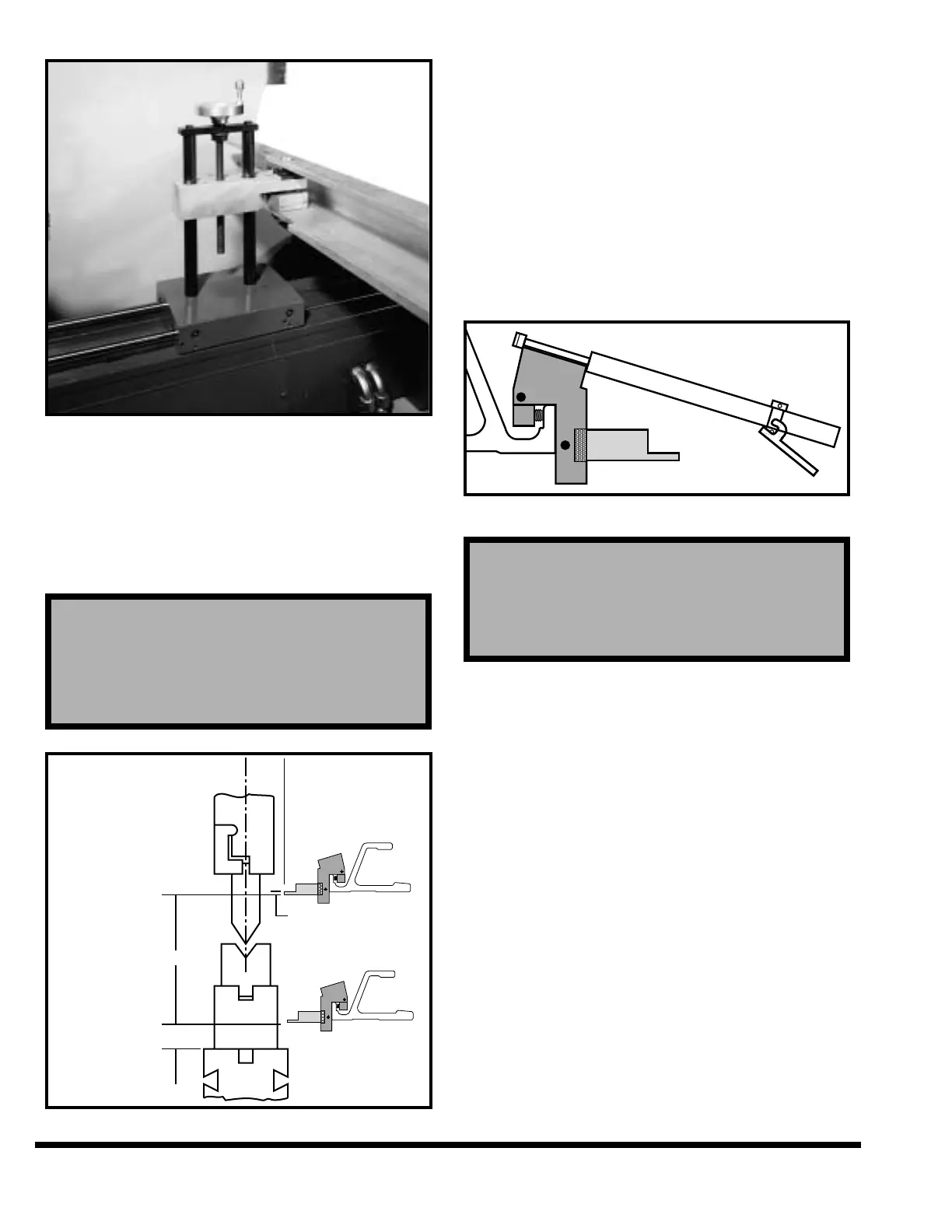

FIGURE 5-12 – Adjusting gage surfaces

The gage finger assemblies should be positioned

left-to-right to contact the part being formed at the

desired gage points. Normally the two gage finger

assemblies should be spread as wide as possible to

provide the most accurate gaging. The gage finger

assemblies are moved along the gage bar by using

the gage positioning tool (Figure 5-13). This tool

releases the gage assembly clamp and holds the

assembly while it is being moved. The gage posi-

tioning tool is used to position the gage assemblies

from the front of the machine. The gage finger

assemblies are installed or remounted by using the

gage positioning tool.

FIGURE 5-13 – Gage positioning tool

Minor part flange differences (end-to-end) can be

corrected by adjusting the individual gage fingers

either forward (to shorten flange) or backward (to

lengthen flange). First remove the gage assembly

from the backgage bar. Loosen the finger by pulling

out the locking knob (Figure 5-7) and turning knob

counterclockwise. The adjusting collar has a total

range of .06” (1.5mm) adjustment.

Adjust the collar either forward or backward the

desired amount. Reseat finger shoulder tightly

against adjusting collar and tighten the locking

knob. All gages are shipped from the factory zeroed

from the centerline of the ram with the gage assem-

bly at .00” position.

Note: The locking pin spins freely unless it is pulled

out. This allows the knob to rest against the

backgage face, thus preventing the finger

from being unlocked while the assembly is in

position on the gage bar.

IMPORTANT: Do not use standard gage finger

assemblies when gaging plates or sheets

that weigh over 100 lbs. (45 kg) on the CNC

CAUTION

The following gage finger adjustments should

never be made while the gage assembly is in place

on the backgage. Always use the gage positioning

tool to remove the gage assembly.

Loading...

Loading...