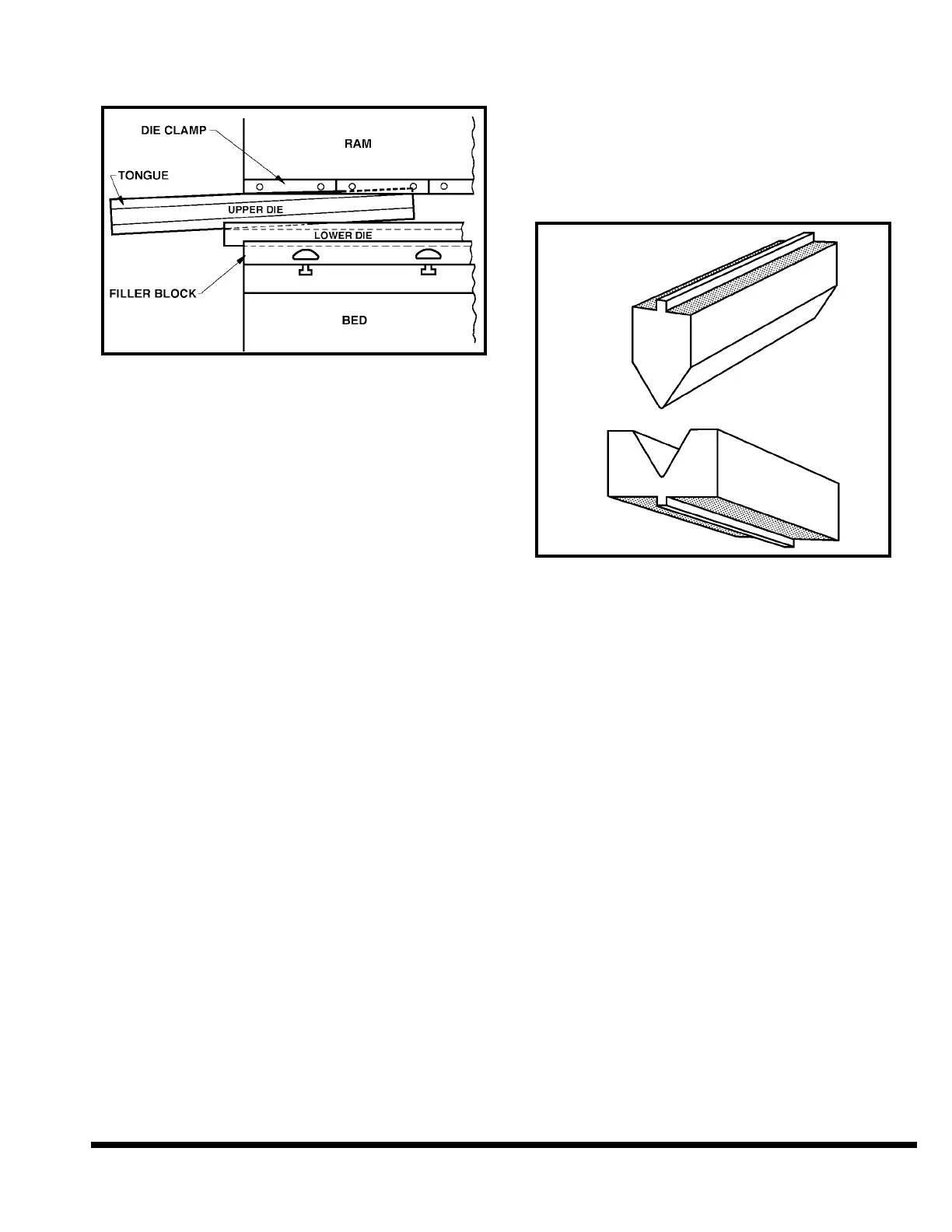

Note: Short, lightweight dies may be installed

as a set and slid into position.

FIGURE 5-5 – Die positioning

✦ Moderately tighten the ram die clamp nuts to

prevent the upper die from falling when the

ram is raised. Also tighten the appropriate

filler block set screws to secure lower die to the

filler block. Turn the OPERATOR CONTROLS

selector to “ON”.

✦ Use the RAM UP button to raise the ram .125”

to .25” (3.2 to 6.4mm). Turn the OPERATOR

CONTROLS selector to “OFF” and remove key.

✦ Visually align the upper and lower dies. Shift

the filler block front-to-back to obtain rough die

alignment.

✦ Turn OPERATOR CONTROLS selector to “ON”.

✦ Inch the ram down using palmbuttons until the

upper die is seated. In SET-UP MODE, the

machine’s hydraulic pressure is limited to 10%

of the machine’s capacity. For example, for a

centered die set on a 400 ton FM, the tonnage

is thus limited to 40 tons (355.8kN); however, if

centered under one housing, the tonnage is

thus limited to 20 tons (177.9kN).

IMPORTANT: When seating dies it may be

advisable to place wood blocks or soft

metal between the dies to prevent damage

to the dies. Short dies must have sufficient

shoulder area to prevent sinking into the

ram, bed or filler block.

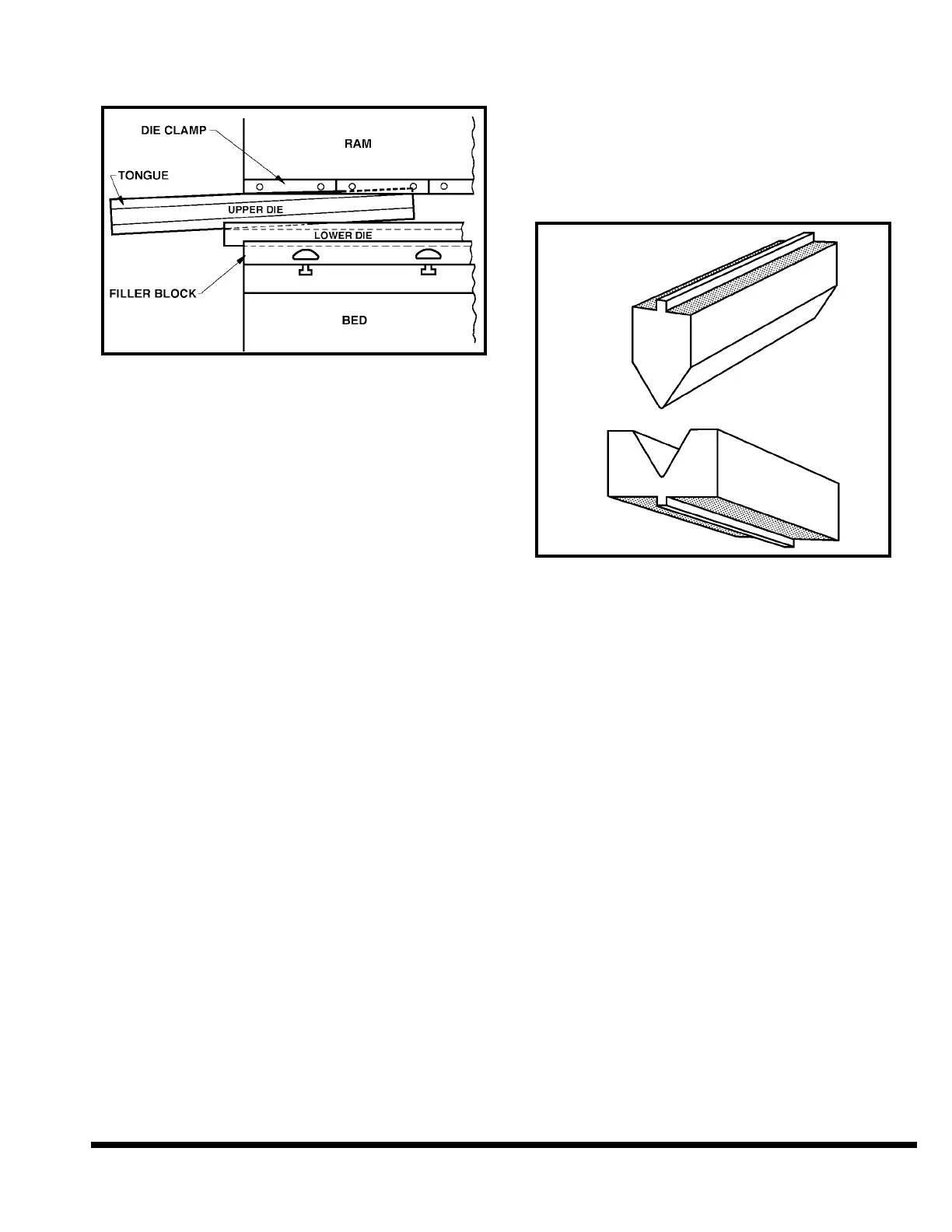

The hydraulic components and machine

frame members are safeguarded against

overload by a relief valve in the hydraulic

circuit. However, care must be taken to pro-

vide enough area under upper and lower

dies to prevent them from sinking into the

ram nose or bed top due to highly concen-

trated loads. This is the shaded area

shown in Figure 5-6. The minimum area

(sq. in.) for each die to prevent sinking may

be calculated by this formula:

Die Area = MAXIMUM TONNAGE / 15

An example for a 400 ton machine, the

minimum die area for a capacity load is

400 divided by 15, or 26.7 square inches.

FIGURE 5-6 – Seating dies

✦ Fully tighten the die clamp nuts after seating

the upper die. Check the shoulders of the dies

with a .002” (.05mm) feeler gage to make sure

they are seated tightly, both front and back.

✦

Run the ram upwards to provide clearance

between dies to remove wood blocks or metal

strips if used. Then move ram down to establish

clearance equal to at least the metal thickness.

Check the front-to-back die alignment over the

full length of the dies. Realign if necessary. Feel-

er gages should be used to measure front-to-

back die clearances between the upper and lower

dies at both ends and at the center of the dies.

✦ Tighten the filler block to the bed.

✦ Tighten the lower die to the filler block.

GAGING - OPTIONAL BACKGAGES

There are two types of optional backgages available

on the FM, the CNC Plate Gage and the CNC Heavy

Duty Backgage. The X-axis (front-to-back) position-

ing is programmable through the FM’s Multi-Axis

Control. The R-axis (vertical) is also programmable

on the CNC Plate Gage and the CNC Heavy Duty

Backgage when ordered with the optional Program-

mable R-axis feature.

5-3

Loading...

Loading...