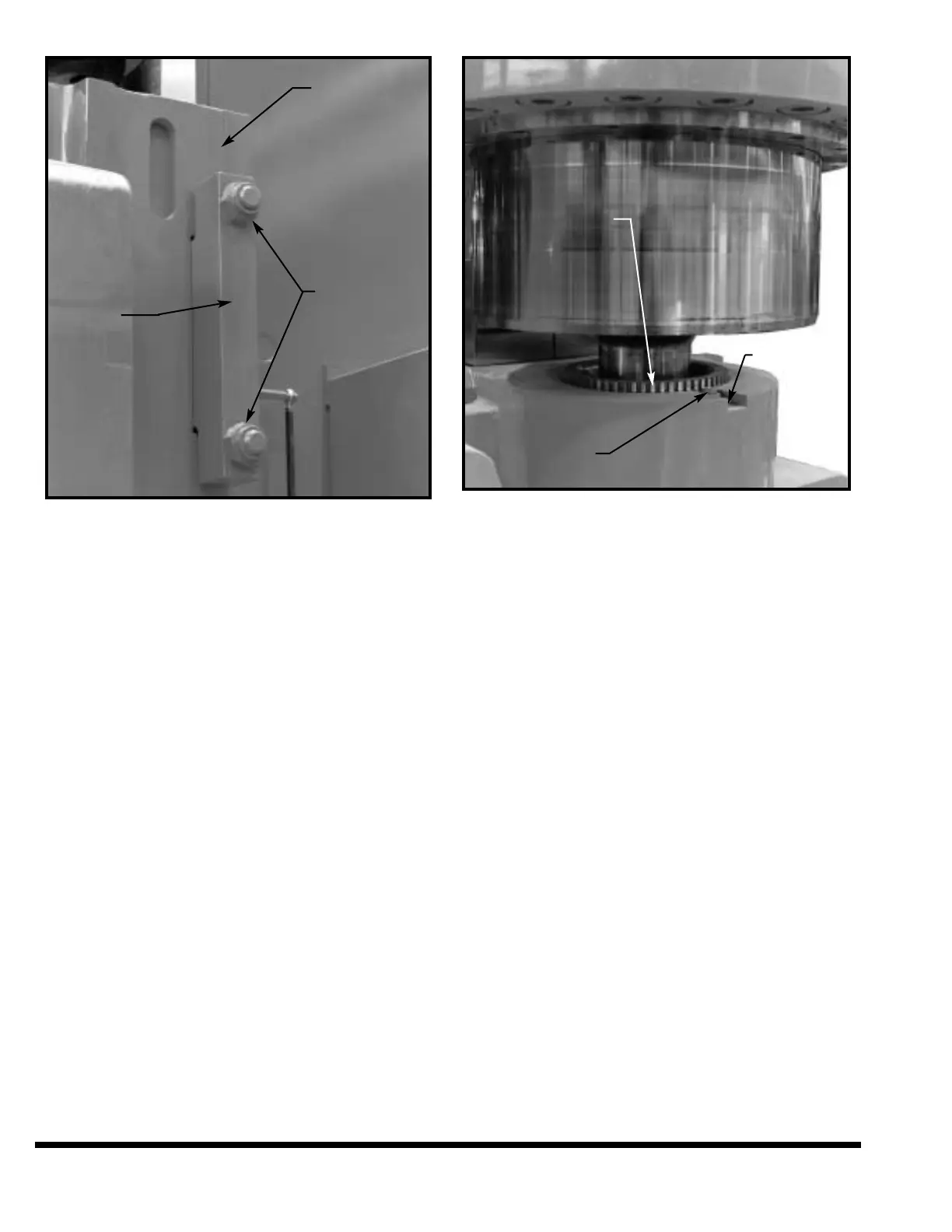

FIGURE 9-10 – Swivel end-guide bearing

1. Adjust swivel end-guide clamp by tightening

the two hex nuts evenly until they are snug,

monthly.

2. Backoff both nuts one-quarter turn. This will

allow about .002” to .003” (.051mm to

.076mm) running clearance.

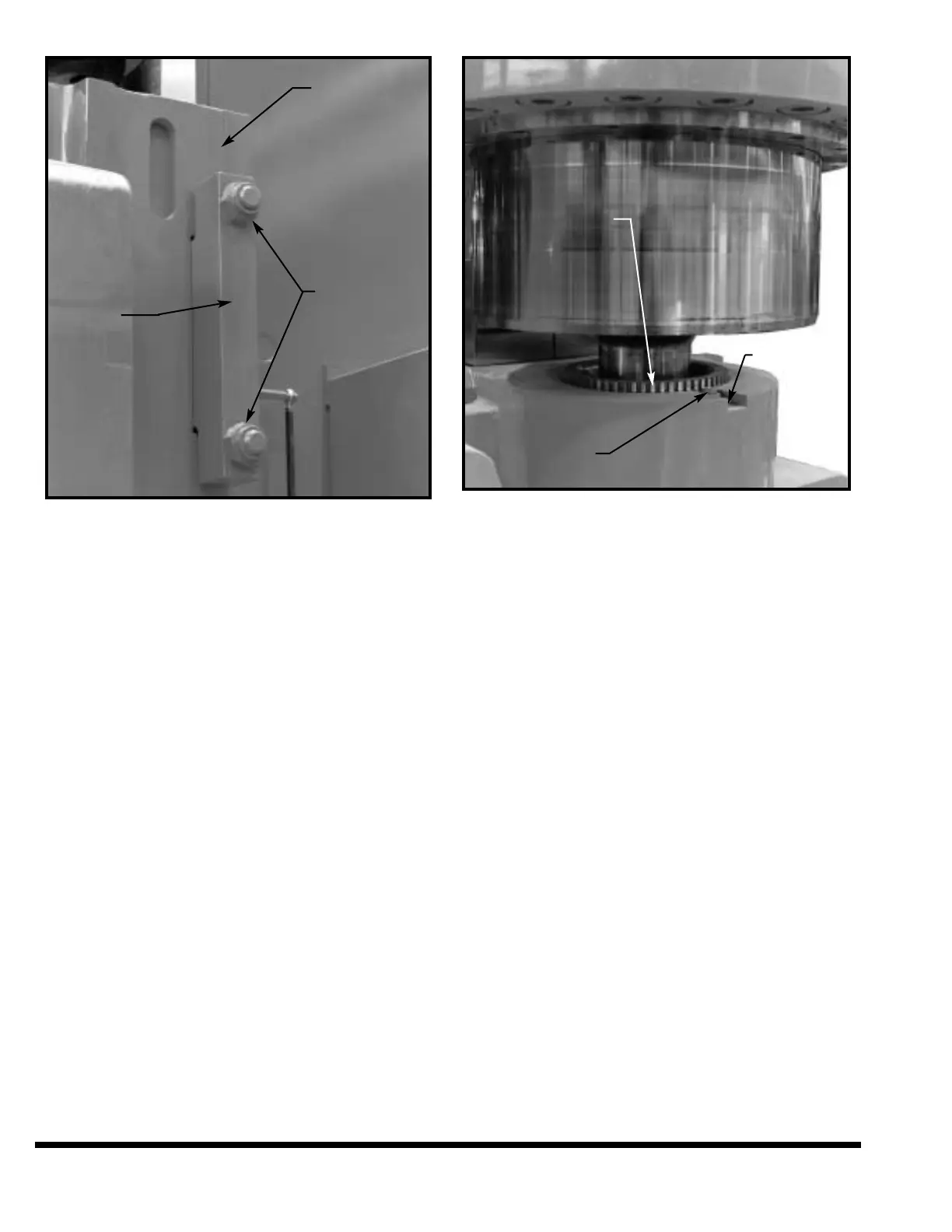

BALL SEAT ADJUSTMENT

To adjust for wear in the piston ball seat:

1. Turn the main drive motor and disconnect

switch on main electrical enclosure OFF. Lock-

out the main disconnect.

2. Select jacks of sufficient capacity to lift the

weight of the ram and ram slides. Place the

jacks at each housing. Protect the finished sur-

faces of bed and ram with wood or soft metal.

3. Raise the jacks until piston ball ends are tight

in the ball sockets.

4. Loosen the lock screw and pry lock plate away

from adjusting nut.

5. Turn adjusting nut clockwise by tapping with a

brass rod until it is tight. Then backoff one

notch. Tap lock plate into the notch and tight-

en lock screw.

6. Repeat Steps 4 and 5 for the other ball seat.

7. Remove jacks.

FIGURE 9-11 – Ball seat adjustment

RAM LINEAR TRANSDUCER

(POTENTIOMETER) ADJUSTMENT

IMPORTANT: This procedure must be done when-

ever the ram clamp bolts are loosened.

1. Set the machine controls:

OPERATOR STATION RIGHT ON

FOOTSWITCH OFF

MODE SELECT SETUP

OPERATOR CONTROLS Selector ON

SUPERVISOR Selector ON

2. Start machine by turning main disconnect ON

and pressing MAIN DRIVE “START” button.

3. Clean the bed top and place a 8.000” - 14.000”

(203.2mm - 355.6mm) steel spacer (or any two

identical length spacers longer than the mini-

mum closed height of the machine) between the

bed and ram at each end, in line with the trans-

ducer rods, and centered under the ram nose.

Check that the ram nose, and not (just) the ram

die clamps, are resting tightly on the spacer(s).

Check with a .001” (.025mm) to .002” (.05mm)

feeler gage. Both ends must be checked. See

Figure 9-12.

4. Use the Palmbutton Operator Station to cycle

the ram down and the “RAM UP” button to

cycle the ram upwards.

5. Jog the ram down until it is about .50” away

from the spacers.

9-8

RIGHT SLIDE

ADJUSTING

NUTS

END-GUIDE

BEARING

CLAMP

ADJUSTING NUT

LOCK PLATE

LOCK SCREW

Loading...

Loading...