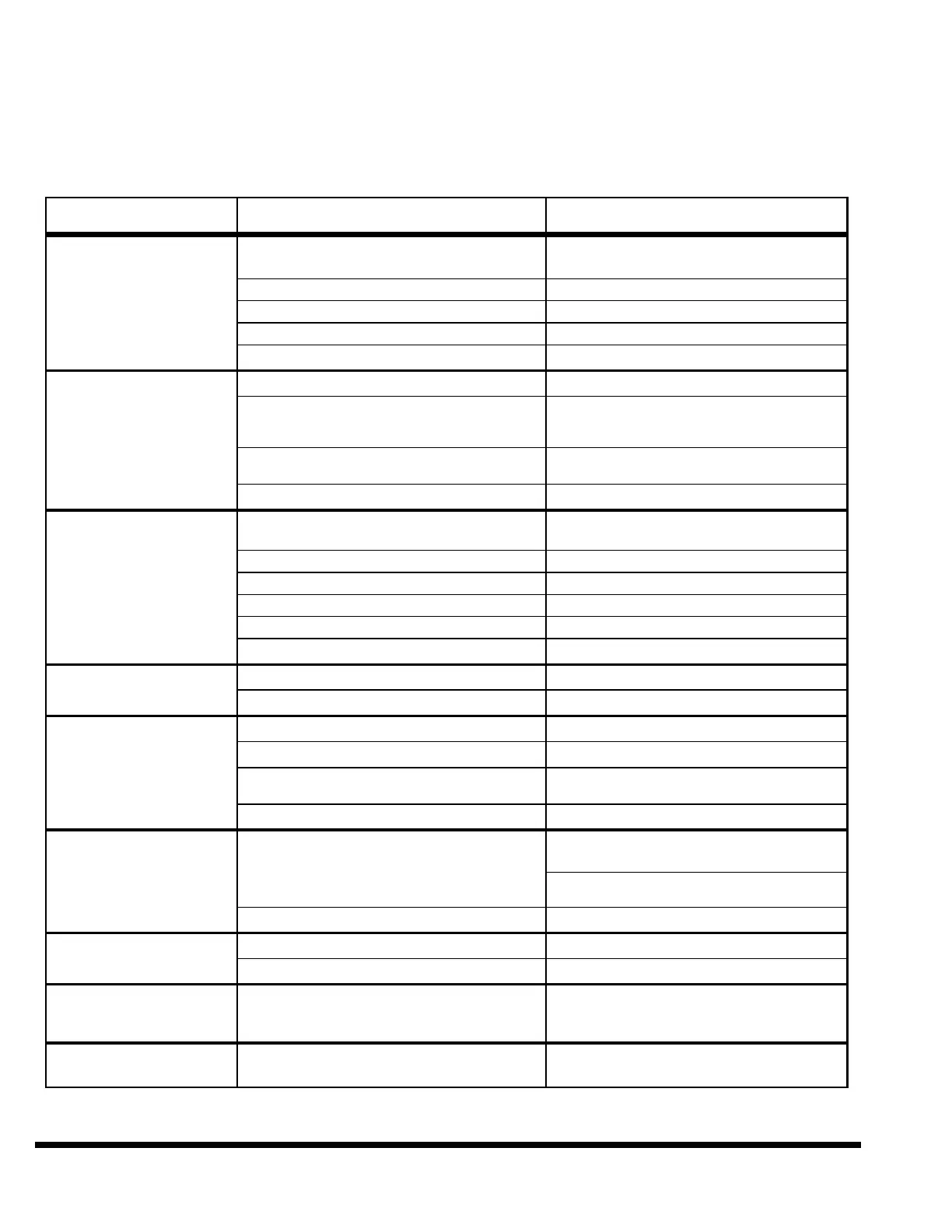

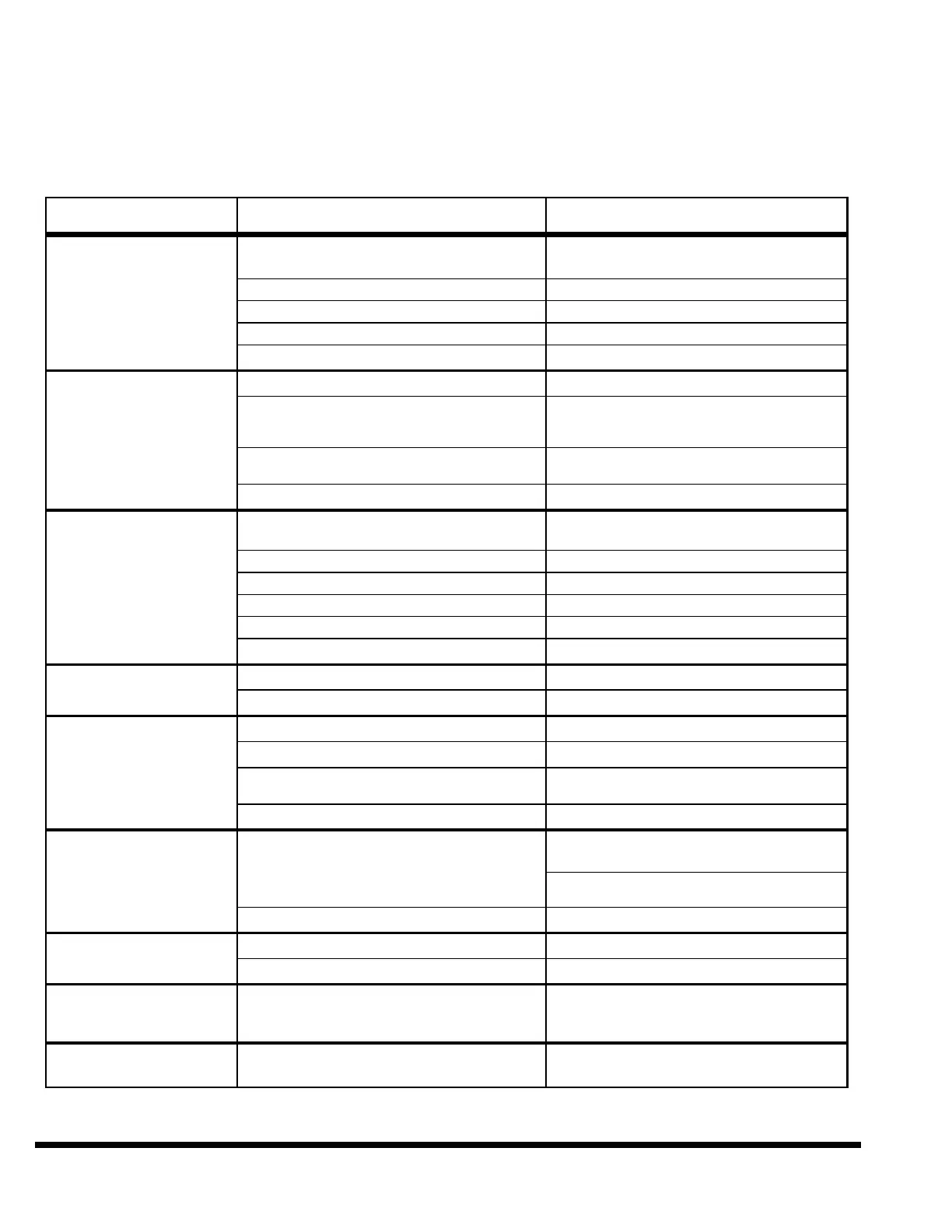

WHAT TO DO

POSSIBLE CAUSE

PROBLEM

If green GROUND CONNECTED light is

OFF, check factory power source.

Check fuses and replace if necessary.

Press manual reset button on starter.

Check and repair or replace.

Check and repair or replace.

Check main relief pressure. (C.I. Service only.)

Check if wire size is sufficient for amperage

shown on main electrical enclosure. Replace

if necessary.

Check factory supply. Correct factory wiring

or contact local electrical utility.

Check hoses.

Turn to “ON” position.

Turn to “ON” position.

Check solenoid valves #1, #2 and #6.

Replace contacts.

Repair or replace.

Replace high current output board.

Check hydraulics.

Replace transducer.

Contact CINCINNATI Service.

Lower STROKE REVERSAL position.

Reset SPEED CHANGE position.

Check solenoid valve #5.

Increase setting.

Tensile and yield strength of material is too

high. Check material.

Improper dies for material and/or bend.

Check die application.

Center the load.

Contact CINCINNATI Service.

Replace printed circuit board.

Replace transducer.

Check for correct electrical signal and valve

spool shift. Repair or replace.

No power to machine.

Blown fuse(s).

Motor heaters.

Low power supplies.

Any system failure.

Main relief valve pressure set too low.

Electrical leads to machine too small.

Insufficient supply voltage at machine.

Leak in reservoir hose lines.

OPERATOR CONTROL or MODE SELECT

switch is in “OFF” position.

Proper operator selector is not turned ON.

Valve malfunction.

1M contact not closed.

Defective input from footswitch.

Defective valve driver.

Ram motion stopped.

Defective transducers.

Defective tonnage control.

STROKE REVERSAL position set too HIGH.

Ram does not shift to forming speed from

HIGH speed.

Tonnage reversal value set too LOW.

Attempting to make “over capacity” bend.

Load not centered left or right on machine.

Defective tonnage control.

Defective control printed circuit board.

Defective transducer.

Valve malfunction (Solenoid #3, #4 and #5).

Drive motor will not start.

B

M

L

A

Main drive motor stalls.

E

I

L

Motor is running but ram

cannot be cycled.

P

D

1

D

D

Motor shuts off.

D

Ram reverses before

building up proper tonnage

or completing bend and

highlights TONNAGE on

the display.

R

T

Tonnage display readout

reaches maximum

capacity but ram reverses

before completing bend.

Ram completed bend but

will not reverse.

On up stroke, ram

continued up past full top

stroke position.

On down stroke, ram will

not change speeds.

TROUBLESHOOTING

Effective troubleshooting is usually acquired with experience and by a thorough knowledge of your

machine and its operation. The assembly drawings, including hydraulic and electrical schematics (includ-

ed with this manual), should be used as troubleshooting aids. The following chart has been developed to

present typical effects which indicate trouble spots in the machine system.

Loading...

Loading...