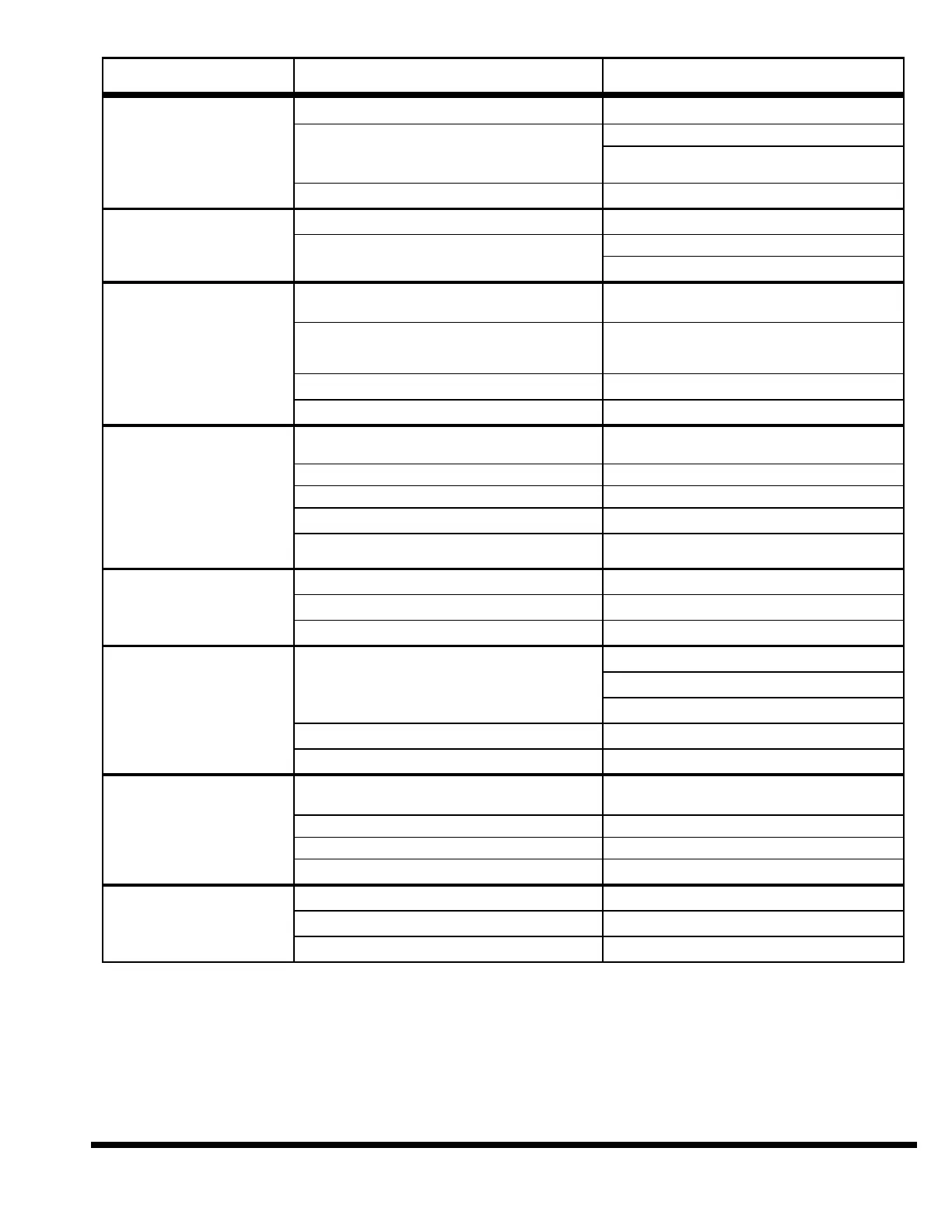

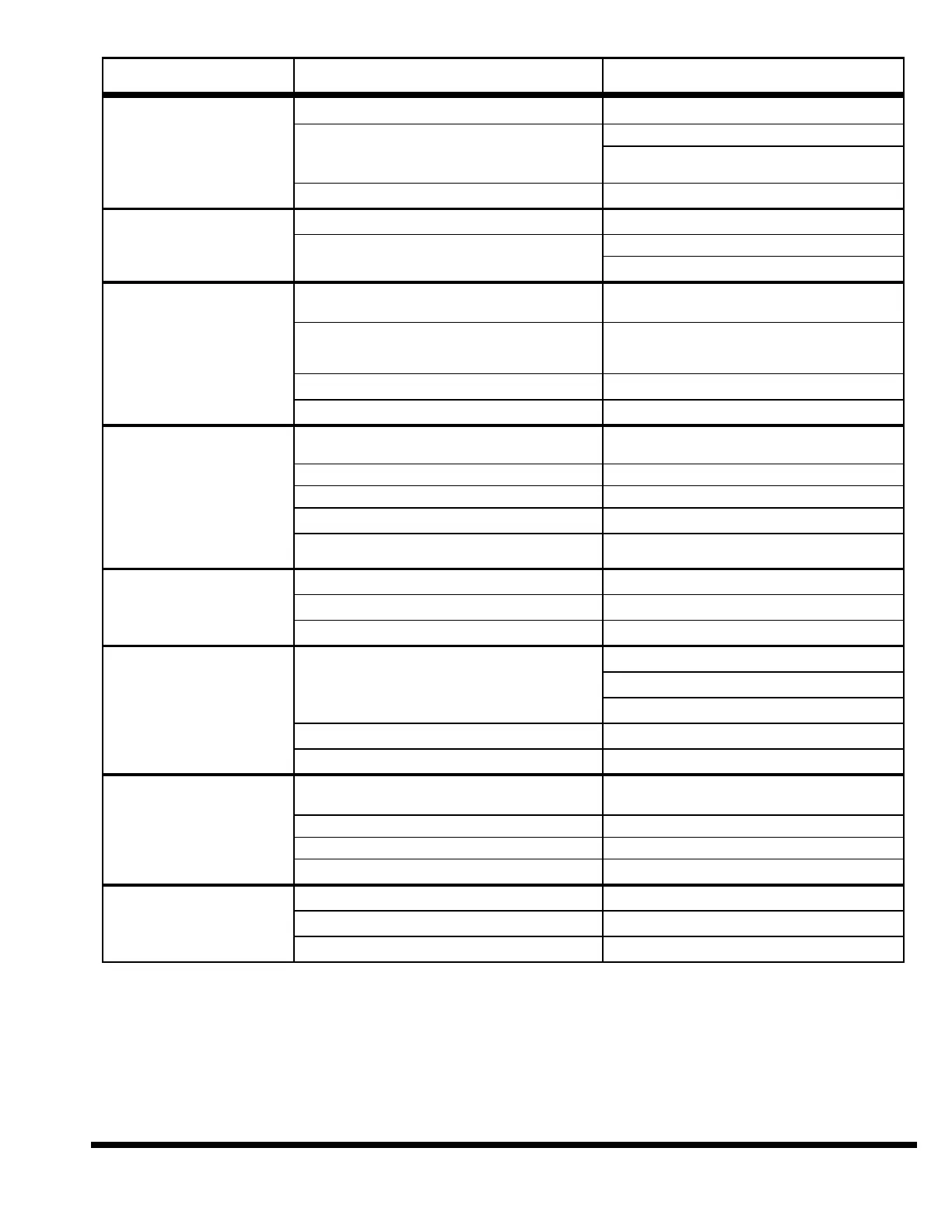

WHAT TO DO

POSSIBLE CAUSE

PROBLEM

Inspect and tighten all fittings and seals.

Remove and inspect.

Exchange left and right valves. Replace

defective valve.

Bleed air.

Replace seal.

Replace level valve.

Replace analog board.

Reset counterbalance pressure - refer to this

section.

Repair or replace.

CAUTION: Block ram to prevent from

falling.

Replace seal.

Close or replace valve.

Check main relief valve pressure - contact

CINCINNATI Service.

Replace seal.

Remove and inspect.

Remove and inspect.

Check solenoid valve electrical signal and

spool shift.

Call CINCINNATI Service.

Check and replace.

Adjust if necessary.

Clogged inlet line.

Low fluid level.

Contaminated fluid - replace.

Overhaul - replace.

Loose connections.

Check speed change point and adjust.

Inspect and replace.

Replace encoder assembly.

Tighten.

Center load on machine.

Tilt ram to compensate or replace dies.

Shim dies.

Air entering prefill area thru piping or seals.

Slow or erratic operation of prefill valve(s).

Air in Auto Crown (optional).

Piston seal leaking.

Level circuit failure.

Counterbalance valve pressure set too low.

Defective counterbalance valve.

Piston seal or piston rod seal leaking.

Cylinder bleed valve open.

Main relief valve pressure set too low.

Piston seal leaking.

Fill valve(s) remain open.

Defective fill valve(s)

Fill pilot valve.

Temperature control sensor set too high.

Defective temperature control sensor.

Check stand-by pressure.

Cavitation.

Worn pump.

Air in fluid.

Speed reversal position too close to material

contact point.

Improper or worn dies.

Defective transducers.

Loose transducers.

Off-center machine loading.

Worn dies.

Machine and / or die defection.

Hesitation of a cylinder

at speed change and / or

erratic leveling at the

bottom of the stroke.

Ram goes out-of-level

during bend and shuts

off drive motor.

Ram drifts down rapidly

when in idle - this can

result in ram tilt beyond

limits, shutting off drive

motor.

Ram stalls during bend -

will not reverse direction

or reach maximum

capacity.

Hydraulic fluid is exces-

sively hot (machines

equipped with oil coolers).

Noisy pump.

Inconsistent bends.

Non-uniform bends

(end-to-end).

Loading...

Loading...