Plate Backgage. Damage to adjustable fin-

ger holder could result. Use Plate Gage

Blocks for these applications. Never allow

workpiece to contact aluminum gage bar.

Bar damage could result.

PROGRAM GAGE POSITION(S)

Now that the gage assemblies and the gage fingers

have been positioned left-to-right and vertically, the

backgage can be programmed for its front-to-back

position(s).

The actual position of the gage in relation to the

tooling is selected when entering a program into the

Control. This procedure is described under MULTI-

AXIS CONTROL PROGRAMMING, “FLANGE

DIMENSION” and “BEND ALLOWANCE” in SEC-

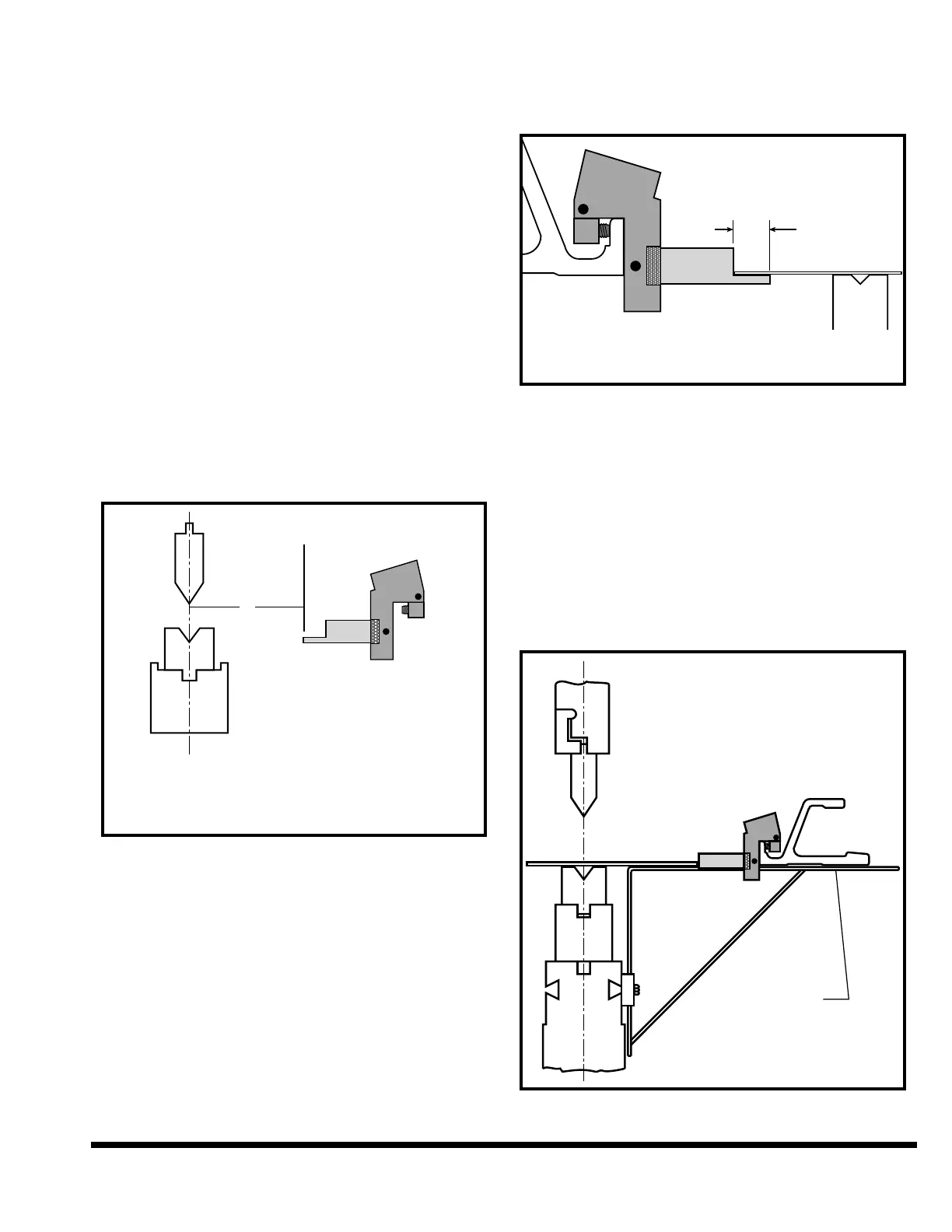

TION 7. Actual gage dimension from the centerline

of the tooling to the gage surface is determined by

two program inputs, flange dimension and bend

allowance. Bend allowance input is the sum of bend

allowance and finger offset. See Figure 5-14.

FIGURE 5-14 – Figuring actual gage dimension

Normally the control will position the gage bar rel-

ative to the ram centerline for a gage surface that is

4.000” (102mm) in front of the face of the gage bar.

This is correct when using standard gage finger

assemblies with 3.000” (76mm) long fingers, along

with tooling that is centered on ram centerline.

Shorter gage assemblies require negative offset and

longer assemblies require positive offset values.

Plate Gage Blocks require a -3.000” (-76mm) offset

since their gage surface is 1.000” (25.4mm) in front

of the gage bar. (Note: Put this offset in the Bend

Allowance value.)

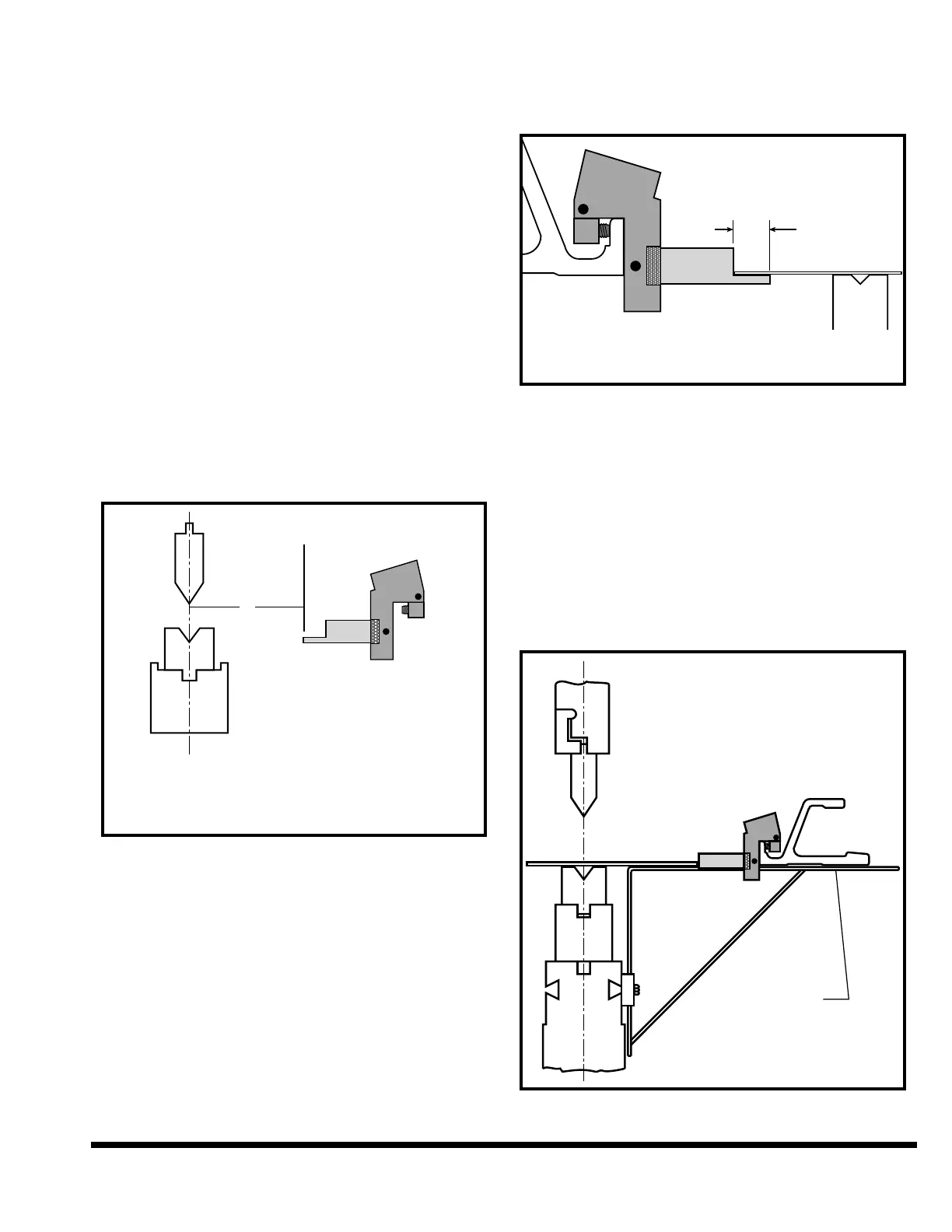

The 1/4” (6.4mm) gage finger can also be used as a

sheet support as shown in Figure 5-15, for light-

weight sheets.

FIGURE 5-15 – Gage finger used as sheet support

WORK SUPPORTS

Two work supports for light gauge material are fur-

nished with the optional backgages. They are

intended to be used in the rear of the bed when long

backpieces (which droop away from the gage sur-

face) are formed. These supports attach to rear

dovetail slots in the bed and should be positioned

at same height as the top of lower die. Figure 5-16

shows a typical work support set-up. Make sure

backgage bar clears the work support.

FIGURE 5-16 – Typical work support setup

dimension must be offset in the program.

Loading...

Loading...