will get into the corners. Do not use an air hose

because the pressure could drive grit and dirt into

the bearing surfaces.

The front vertical bed mounting faces of the hous-

ings must be plumb. This can be checked with the

level in squaring head of an ordinary machinist’s

square or with any level that can be used on a ver-

tical surface. If the housings are not plumb, loosen

the nuts on foundation bolts. Use leveling screws in

housing feet to raise or lower machine. Do not allow

machine to permanently rest on these screws. On

larger machines place a jack under lifting lug to

raise housing. Insert flat steel shims under the

housing feet as required. Lower housings and

retighten foundation bolt nuts. Recheck the plumb

on housing faces and repeat above procedure if

necessary until the housings are plumb.

Remove the bed from rear of housings using a

chain or cable of adequate capacity. DO NOT USE

HOUSING SLOT IN THE BED TO LIFT THE BED.

Remove the bed shoes and bed bolts from shipping

box. Clean the bearing surfaces of the housings

and the matching bed surfaces, and the bed shoes

and bolts. Carefully lubricate all finished surfaces

of the housings where the bed fits. Also lubricate

top and bottom surfaces of bed shoes. Use EP #2

Lithium grease (C.I. grease H-2EP). Place bed shoes

into position on the housings. Match the markings

on housings and bed shoes. Place the bed into posi-

tion on housings and insert bed bolts into bed.

Loosen all foundation bolt nuts and tighten bed

bolts securely. Retighten the foundation bolt nuts

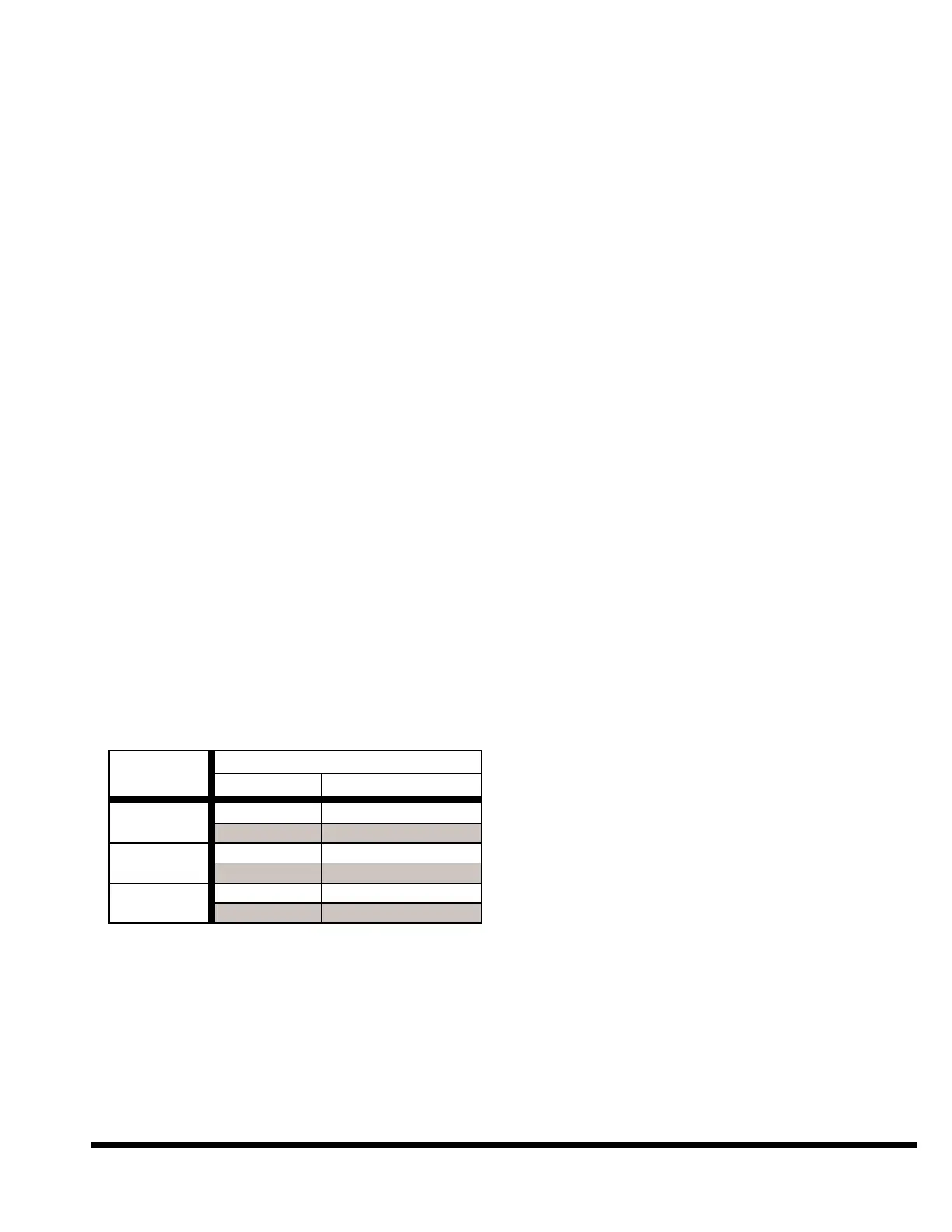

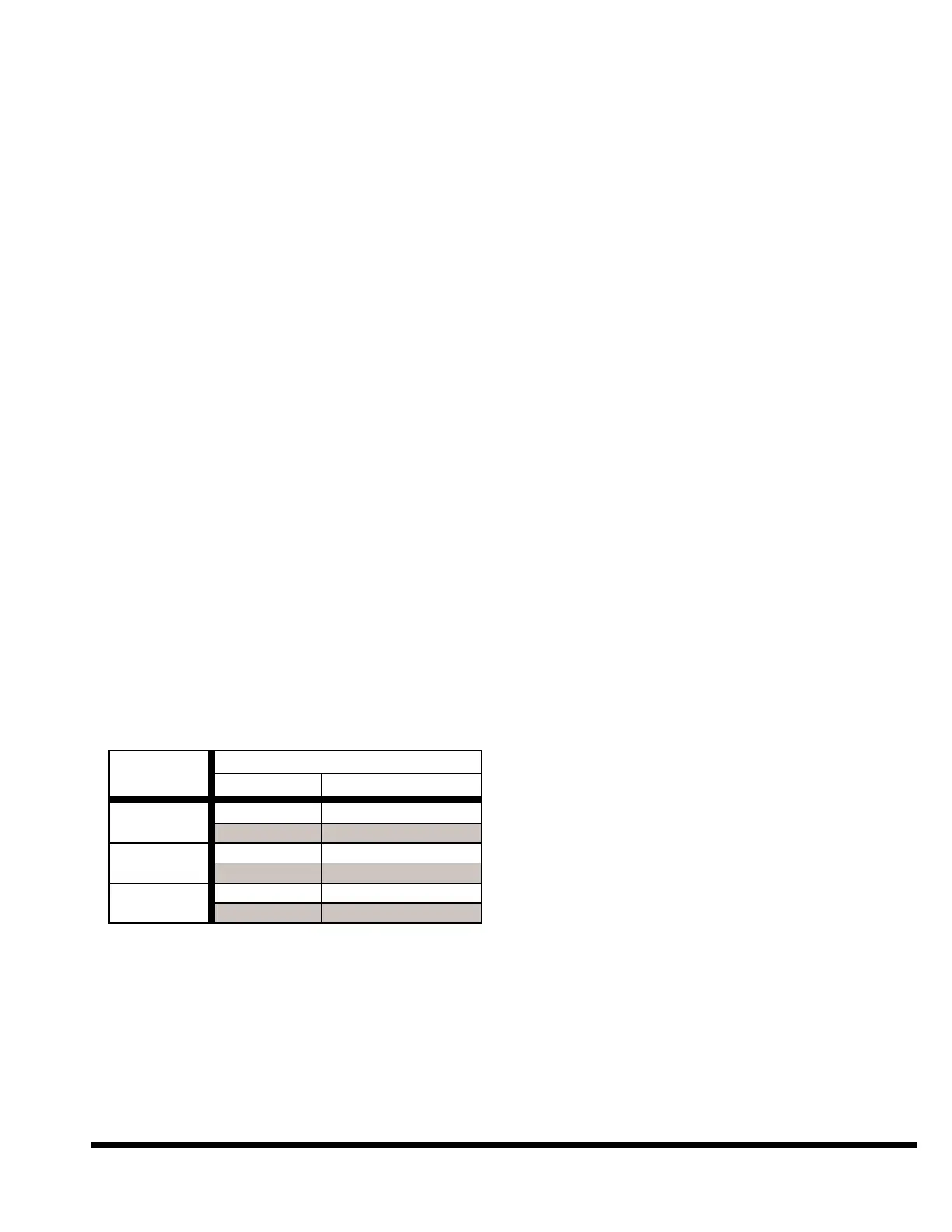

securely. See Figure 2-3 below for bed bolt and

foundation nut seating torques.

FIGURE 2-3 – Seating torques

Check your work with feeler gages. There should be

no clearance between the bearing surfaces of the

housings and bed. If there is clearance, either the

bed bolts are not tight or there is grit between the

bearing surfaces. There should also be no clear-

ance between the bed shoes and the bed.

Place a jack between bed top and the bottom of

both ram slides. Protect the finished surfaces with

wood or soft metal. Loosen, do not remove, the

screws holding four ram slide clamps to ram slides.

Remove plastic laminate shipping strips from under

ram slide clamps. Pry ram slides out enough to

remove the plastic laminate from between the ram

slides and guides.

IMPORTANT: These plastic laminate shipping

strips must be removed before running the

machine.

Use the recommended cleaning solvent to flush

protective grease from between slides and guides.

Allow surfaces to dry and lubricate with oil. Push

ram slides back against guides. Securely tighten

the ram slide clamp bolts. Lower both jacks equal-

ly. If ram follows the jacks down, do not allow one

end to get out-of-level more than one inch. Remove

the jacks.

Tighten the lock-down screws between the housings

and bed. They are located at the bottom of each

housing where the housing fits through the bed.

The encoder lower mounting brackets were removed

for shipment. A CINCINNATI INCORPORATED Ser-

vice Representative will install and adjust the

encoders at start-up.

Erection of assembled machines is completed. Pro-

ceed to the information on CLEANING.

ERECTION - DISASSEMBLED

MACHINES

The 400FM x 16' and larger press brakes are

usually shipped disassembled. CINCINNATI

INCORPORATED Service Representative should

be scheduled to assist with installation of

machine. Before setting-up the housings, open

the shim packages. Remove the thickest shim

from each package. Place one shim at each foun-

dation bolt location. The top surfaces of the

shims should be about level. Thinner shims can

be used to obtain this level condition. Then

place a 1/8" thick shim at the four front feet

locations to deliberately make the front of

machine high. It is then much easier to raise the

rear housing feet to obtain final leveling when

the press brake is in position. As an option we

recommend using a transit to establish that all

four front and rear pads are in the same plane.

The cylinders and slides should be assembled to

each housing. Most machines are shipped in this

manner. Either housing may be set up first. To lift

housing, use a clevis as shown in Figure 2-2. If the

clevis is not available, an adequate strength cable

should be used in the same housing hole. Be sure

Loading...

Loading...